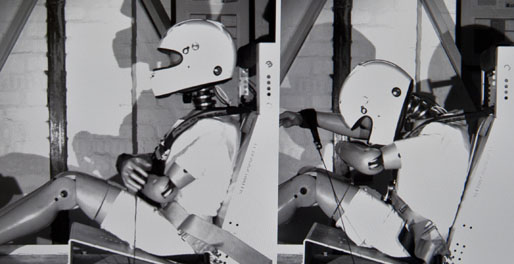

After initial testing together with BMW, the experts at the Leatt Corporation developed their own test structures with which they could simulate the forces acting on bike riders during an accident.

“There were no test bench standards for this device, so we needed to set them ourselves” said Cornel de Jongh, biomedical engineer. During an accident, compressive, tensile and shear forces occur together with strain and bending moments, and these need to be evaluated in combination. “Besides the mechanics, we use the SoMat eDAQlite data acquisition unit from HBM to acquire the signals from our 23 dummy and other sensor channels”, explained Cornel. This extremely rugged amplifier can be used to acquire a wide range of parameters, making SoMat eDAQlite the ‘heart’ of this test bench as Cornel emphasized.

The Leatt Corporation uses HBM's nCode GlyphWorks® software for post-processing the measurement data – powerful software for processing test data in engineering with the focus on structural durability and lifetime analyses.