Intelligent and flexible experimental setups for tests on concrete structures

Aarhus University School of Engineering's Concrete Laboratory provides experimental facilities for all those studying engineering in the Danish city of Aarhus. As student numbers have increased, demand for places in the laboratory has grown - with the result that the laboratory needs a flexible, smart solution for collecting measurement data, so that as many experiments as possible can be carried out. HBM has supplied equipment including five QuantumX MX840B units and a range of different transducers, all meeting the requirements of a state-of-the-art test laboratory.

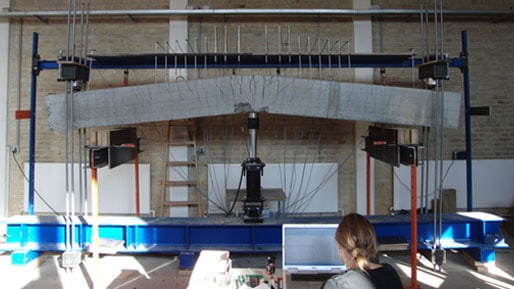

The Concrete Laboratory at Aarhus University School of Engineering is used by the students to carry out both static and dynamic experiments involvingconcrete structures. Aarhus University School of Engineering is an umbrella institution for all engineering courses in Aarhus.The laboratory is being expanded, and the number of students needing to use the laboratory is constantly increasing.

The static experiments are carried out on various types of structures and involve not only fracture of traditional reinforced concrete beams, but also other types of structures that occasionally require adaptable measurementequipment. The laboratory therefore needs to have measuring equipment that is easy to use in many different contexts and in all kinds of setups, so that the students can perform a wide range of experiments without the laboratory having to invest in various types of equipment.

Flexibility and universal use

To satisfy its need for data acquisition from a number of transducers andsensors, the Concrete Laboratory has purchased five QuantumX MX840A units from HBM, along with 24 flow transducers. For the Concrete Laboratory, one of the main advantages of using the QuantumX MX840A for data acquisition is that the unit can collect data from transducers based on various different technologies – whether these are flow transducers, load cells, strain gauges, accelerometers or other measuring equipment.

Thanks to its flexibility, the QuantumX unit can be used universally for the laboratory's many experiments. Another key factor in the laboratory's choice of the QuantumX MX840A was that the unit can be used with equipment fromdifferent suppliers. Electronic engineer Jørgen Holm, who is responsible for the organization and operation of the laboratory, explains:

"The QuantumX MX840A meets our requirement for a high degree of flexibility as regards using the unit with many different types of transducers from different suppliers. That gives us more freedom - so the great flexibility offered by the QuantumX quite simply makes it easier for us to collect a complete set of data from the same experimental setup."

Easy configuration of experimental setups

With students lining up to use the laboratory facilities, it is naturally important that the setups can be put in place quickly and easily, and the experiments performed with a high degree of accuracy right from the start. That also makes demands of the measuring equipment.

"Another key reason why we chose the QuantumX MX840A is that it is a highlyintelligentunit, which makes it easy to work with. We can thus calibrate the equipment using TEDS, which means we can use it together with all our latest equipment and our future equipment, and it makes configuring theexperimental setup uncomplicated and accurate," says Jørgen Holm.

TEDS, which stands for Transducer Electronic Data Sheet, means the data acquisition system can retrieve data automatically from the connected transducers, and the equipment can then calibrate itself - thus ensuring a high degree of precision in the measurements.

A safe bet in teaching

The Concrete Laboratory had previous experience of data acquisition from HBM using Spider8 and Catman Easy, but feels that the new generation of QuantumX data acquisition systems is worth the upgrade:

"We have used equipment from HBM before, and while we've always been happy with it we can see significant improvements in our new QuantumX units – both on the software side and when it comes to the performance of the hardware, which is now significantly more powerful than HBM's previous data acquisition units," says Jørgen Holm.

In other words, the Concrete Laboratory sees the QuantumX as a safe bet when it comes to providing the best possible conditions for teaching the engineers of the future.

Challenge

The Concrete Laboratory at Aarhus University School of Engineering is expanding its facilities as student numbers increase. It therefore needed flexible and intelligent measurement equipment that could be configured easily in different ways.

Solution

The central data acquisition unit is the QuantumX MX840A from HBM, which uses TEDS to calibrate a range of different transducers from both HBM and other suppliers, and which provides the laboratory with state-of-the-art measurement equipment. The laboratory also uses HBM's Catman software.

Result

The Concrete Laboratory is confident that it will be able to use both existing and future transducers with the QuantumX units, enabling it to create a state-of-the-art experimental environment easily, quickly and accurately for the engineers of tomorrow.