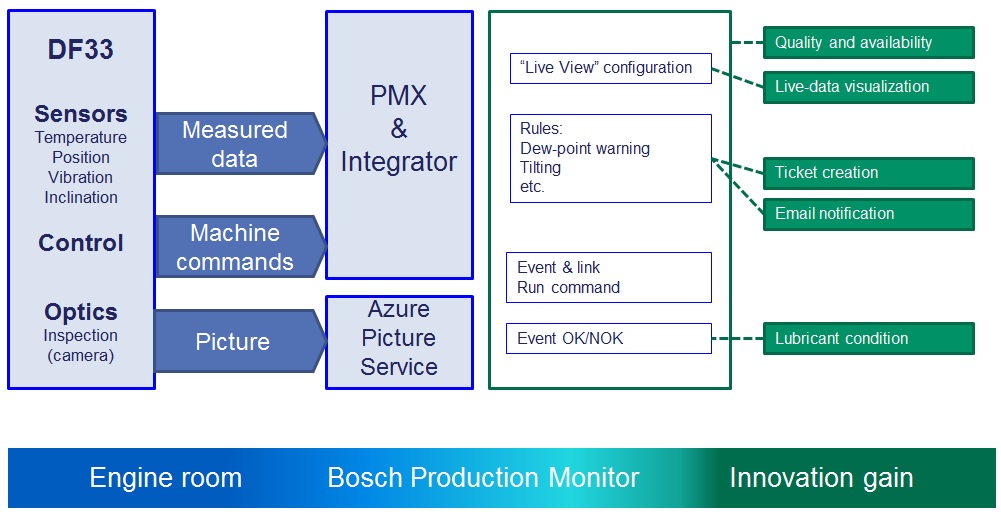

其采用了博世公司的 Nexxed 生产绩效评估软件。这个强大的工具可进行各种分析和评估,从设置警报、创建和发送服务订单并可植入人工智能(AI)。存储自学习规则,以便以后能够提前识别和及时报告生产缺陷。

PMX 和 HBM 云存储使生产过程更安全、更高效

HBM 始终致力于为客户提供高效灵活的 工业 4.0 集成解决方案,减少宕机时间,优化生产过程。

自 1977 年成立以来,HBM 一直是世界上最著名的校准实验室之一。HBM 也是第一个获得 DKD(Deutscher Kalibrierdienst/德国校准服务)认证的校准实验室。不断扩大的投资确保了最高精度,并最大可能地满足不断增长的客户需求。

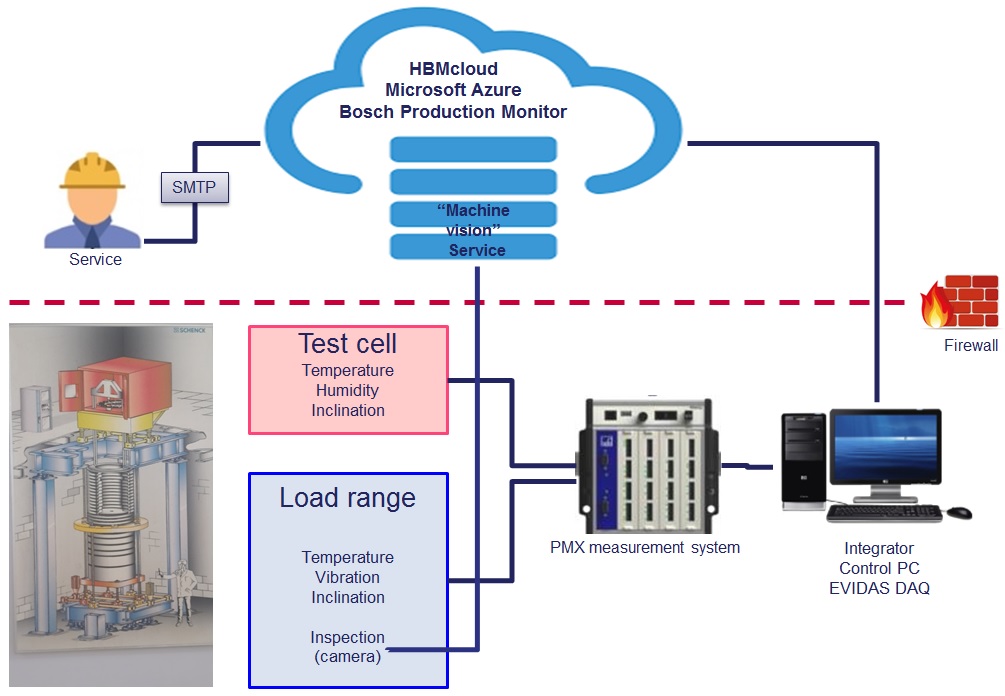

该系统全天候运行,测试的传感器的量程从4.7吨到33吨(部分加载)到100吨。也就是大约 330 千牛的力。在实际生产过程中,机械或空调系统的缺陷会导致成本上升和宕机,必须加以补救。为了实现这一目标,第一个校准系统配备了PMX、HBM的测量技术,包括云连接。

前提是现有的系统控制(PLC)不做任何改变,而将新系统监控时间减少到最低程度。

问题

校准系统采用 330千牛的传感器,待测零件承受了巨大的力。因此,必须确保有效控制且操作安全。此外,气候控制系统或是机械缺陷故障会导致高昂的成本和停机时间。

解决方案

博世和 HBM 一起寻找合适的硬件和软件:大量的过程和传感器数据被集成到内部 PMX 放大器系统中,以高分辨率(数千赫兹)传输到HBM测量数据采集软件。然后,数据以压缩格式以低传输速率(几赫兹)继续传输到HBM云存储。最大的优点是,数据可以根据级别提供所需的详细信息。

结果

本地的原始测量数据提供精确的、并支持人工智能分析。而压缩数据则通过云传输到 Nexeed Production Performance Manager。在那里,为了进行评估,信息被转换成指令、警告或可视化。由于 Nexeed Production Performance Manager被证明是测试站的第一个理想解决方案,HBM 将在未来几个月内将其扩展到 20个不同类型测试系统中。HBM和博世一起合作,确保 HBM 客户能获得带有分析和评估选项的创新测试和测量技术,并能在最短的时间内获得最大性能。

分三步插入并运行

第一步,对系统的运行状态进行分析,确定机器监控的相关测量点。其次是选择合适的传感器和测量技术。在测试室-校准系统的上部,包括多种传感器力传感器和称重传感器,以及监测所使用温度、湿度和倾角传感器。在下半区域,大型砝码由电机驱动产生校准符合。整个过程由温度、振动和倾角传感器监测。

第二步,选择合适的测量技术。 PMX 是一个具有数据采集和实时数据处理功能的多通道测量系统。可进行全面的诊断,并可通过浏览器进行参数化。以19.2 kHz的采样率记录和评估所有测量数据。测量和诊断数据通过标准以太网接口(TCP/IP)传输到物联网路由器中。这个路由器由一台 PC 和数据采集软件组成。

第三步,确定合适的云计算和评估软件。基于云的测量技术最大优势是数据不需要从一个存储位置移动到另一个存储位置。并且可立即使用——在许多情况下可由人工智能而自动实现:HBM 云允许您访问全球范围内的数据(取决于授权),从而改善信息流以进行国际合作。这个策略的一个重要支柱是选择“正确的”云合作伙伴。HBM 采用的是微软 Azure 解决方案 - 可靠,领先,并且数据也可以根据公司所在地的法律要求存储。

快速灵活地连接到工业 4.0

益处

高效联网 新的和现有的设备,并 优化生产过程和产品质量:IOT网关, PMX 和DAQ软件使连接到工业4.0环境更容易实现——且不受自动化逻辑的干扰。应用程序的硬件和软件的精确匹配组合,收集传感器和过程数据,将这些数据传输到制造执行系统、云应用或本地监控的系统,并进行过程数据分析。

- 提高生产力和效率

- 分三步插入并运行

- 满足不同需求的模块化系统

- 可扩展且健壮的测量硬件(PMX)和软件

- 经得起未来考验的开放软件体系结构和HBM云应用