KA-RaceIng

As we know, racing always aims to be faster, lighter, and more innovative.

As a Formula Student team of the Karlsruhe Institute of Technology, KA-RaceIng has been following this approach since 2006 and is now developing the 15th generation of racing cars.

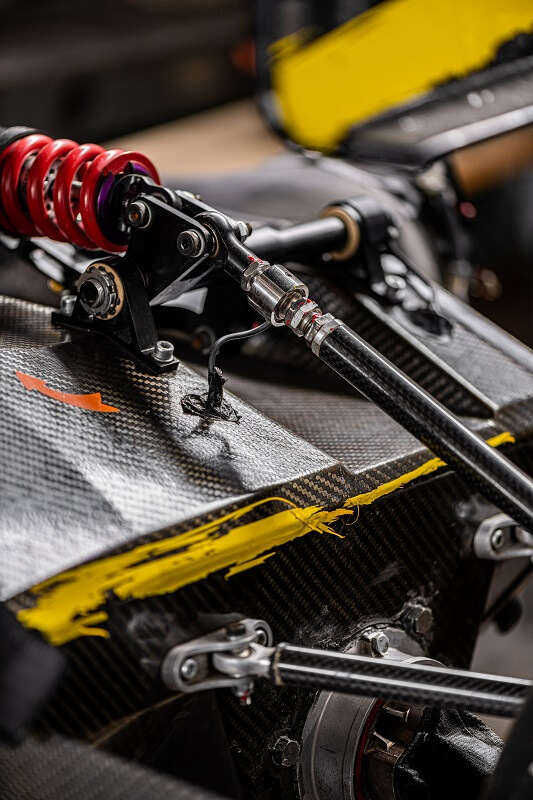

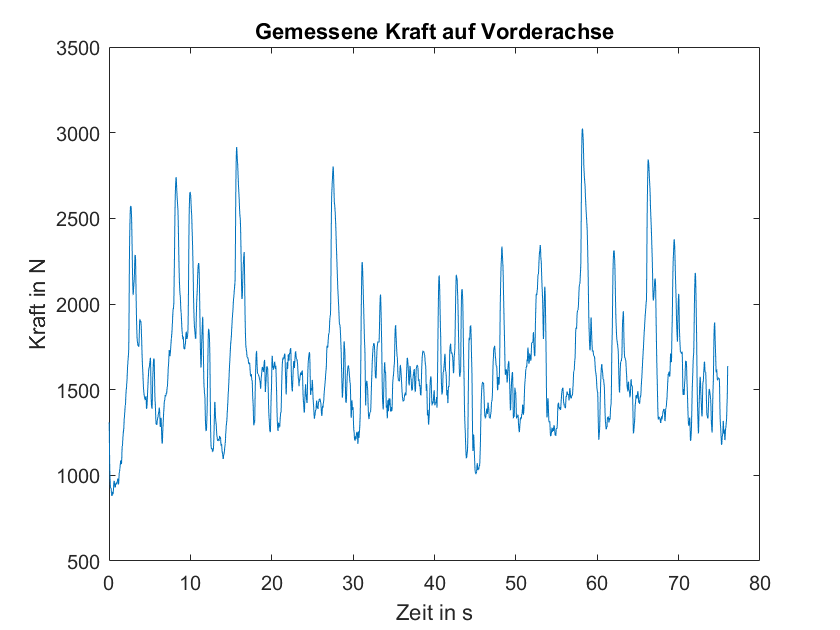

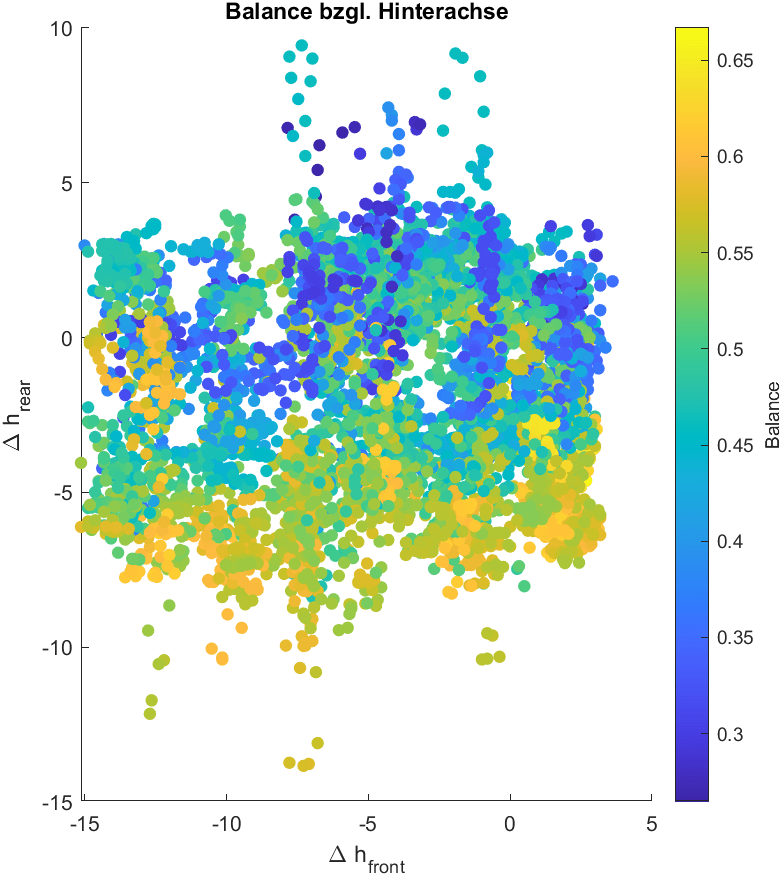

Monitoring the entire product life cycle through sensors is enormously important and helpful, especially for building prototypes in the context of Formula Student: from implementing the concept idea through validating it on various test benches to supporting the driver on the track. For this reason, we use various HBK force transducers such as the U9C force sensors, the 20kN force washer and the 50kN force sensor.

Thank you for your support and cooperation, even at special times!

More about KA-RaceIng