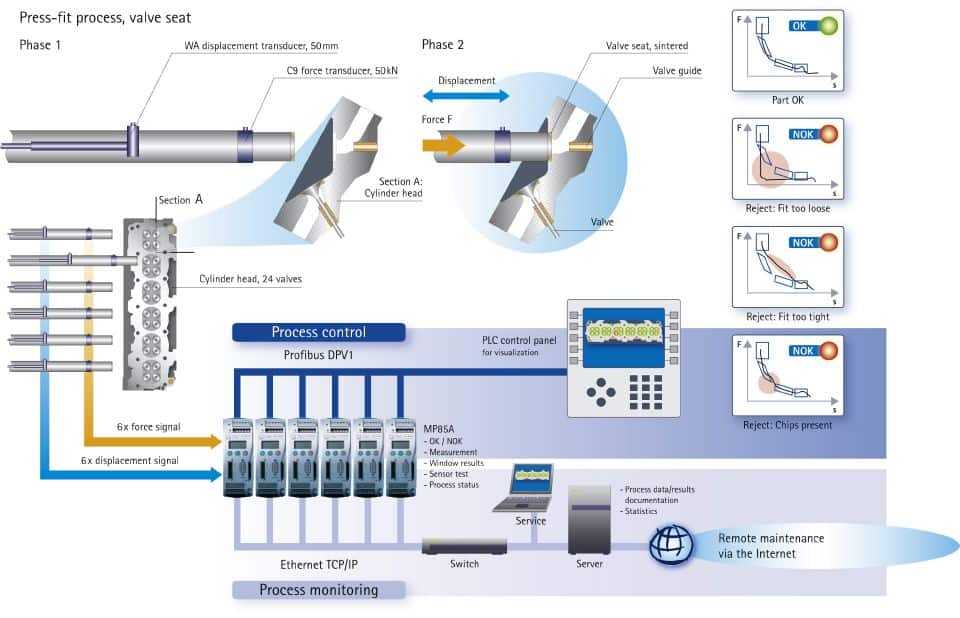

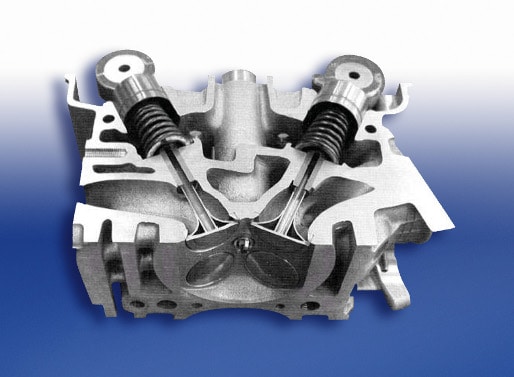

In combustion engines, valve seats and valve guides are subjected to special loadings. There are thermal loads as well as mechanical loads, produced by the ignition pressure or by the valve disk coming down hard when closing. This is why sintered materials are used in engines of the latest generation. The cycle times, that is to say the production times for assembling a cylinder head with 24 valves, have to be continually reduced, for economic reasons. The automotive industry is demanding 70 seconds or less for this.

Successful process monitoring…

With cylinder head assembly, the requirement is to be able to detect errors from the force/displacement characteristic curve produced when press-fitting the valve seats and to draw conclusions about their causes. The results of all the processes must be stored, so that they can be recalled when necessary. A central PLC is responsible for all machine control.

…with MP85A FASTpress controllers

The new MP85A is linked to the machine control via the industrial Profibus fieldbus. Parallel monitoring on a PC is via Ethernet. As the MP85A units also have Profibus DPV1 functionality, they can be specifically controlled by the PLC. The external tolerances of the cast body interfere with the actual press-fit displacement. Normally this would mean that you would need to increase the “not OK” (NOK) limits of the evaluation system to such an extent that sensitive error recognition would no longer be possible.

Although the external tolerances of the die-cast body are superimposed on the press-fit displacement, reproducible press-fit curves can now be obtained.

Probing the causes of errors

HBM's PME Assistant software offers a wide range of functions to detect errors. Each valve seat on the cylinder head can be assigned its own tolerance window with its own evaluation criteria for the press-fit process. This provides an overview of where on the cylinder head problems occur.

Data capture and processing with the PME Assistant

NOK curves are quickly detected with the PME Assistant software. The search can be targeted by date, component and serial number or even by the required press-fit point on the cylinder head.

Intelligent measurement technology for increased efficiency

The Ethernet interface of the MP85A permits measurement curves and results to be directly transmitted to and stored on a PC in the production line, or a file server on the corporate network. You can directly interface the MP85A with your existing network structures using TCP/IP. In addition to increased data security, this allows you to perform remote maintenance and diagnosis.