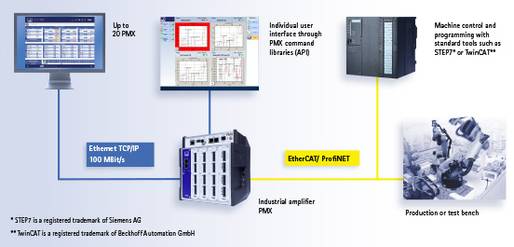

Development cycles need to be shortened and costs reduced for companies to remain competitive today. At the same time, raw materials, energy and the workforce are getting more expensive. It is necessary to improve the efficiency of the process without influencing the quality of the product. Automation is the answer to these numerous challenges. The measurement technology of today needs to get ready for the demands of automation technology tomorrow - from the sensor to the software.

Whether in the test environment, production or service and maintenance - automated sequences ensure added efficiency and lower costs in all areas. The automation of test and production facilities for instance permanently saves money by saving power, using resources more carefully or by improving production sequences and thus product quality.

Systems that are intelligently equipped also help to avoid expensive production downtimes. Automation technology not only makes the service and maintenance of systems easier and faster, it also signals potential risks for production long before they turn into real problems.

High requirements for measurement technology

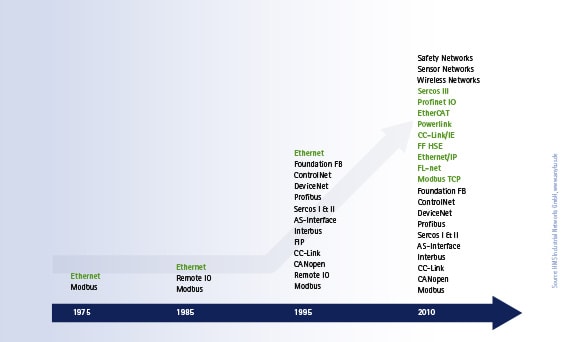

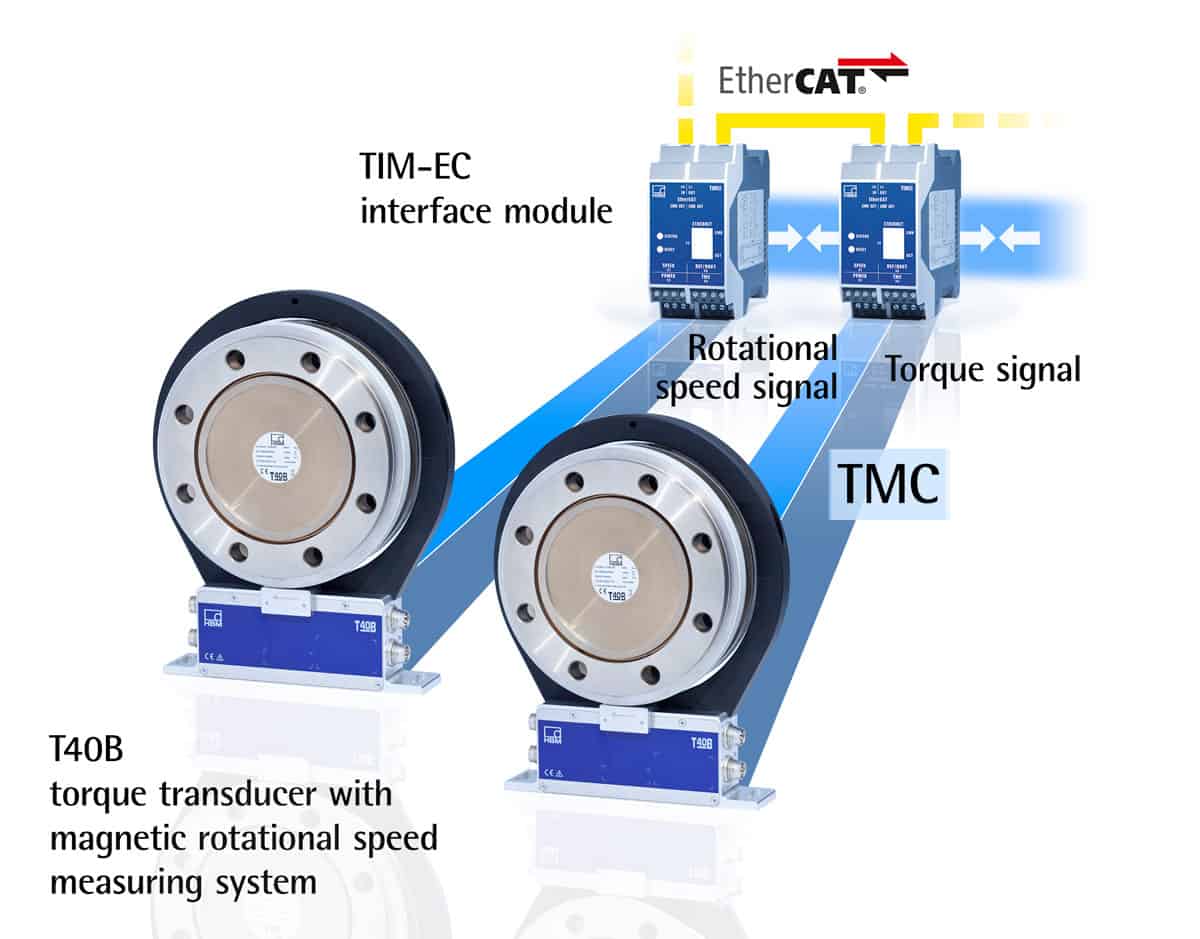

As a part of automation technology - be it interfaces, data transmission rates or integration capability - measurement technology must meet high requirements in order to keep ahead in this branch. The latest technology is necessary.