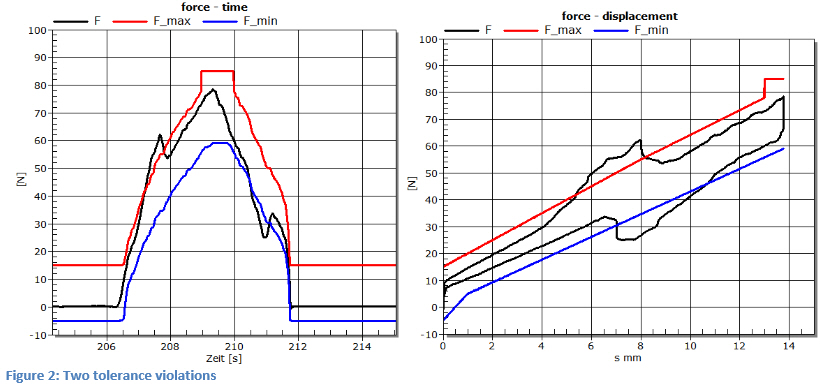

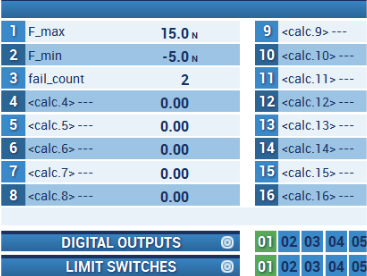

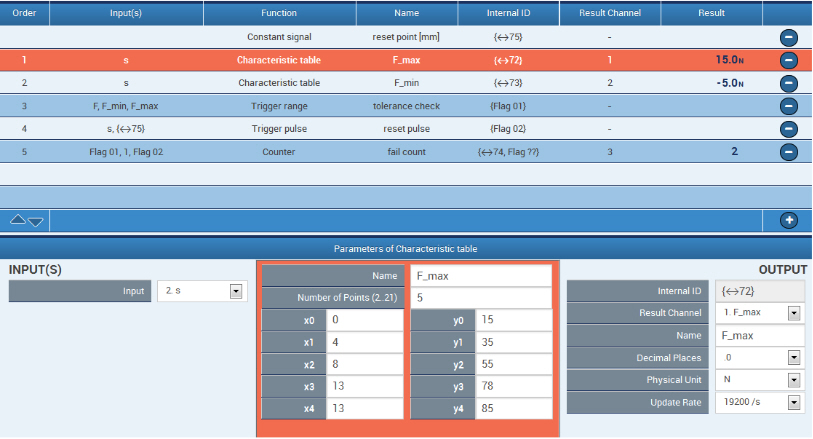

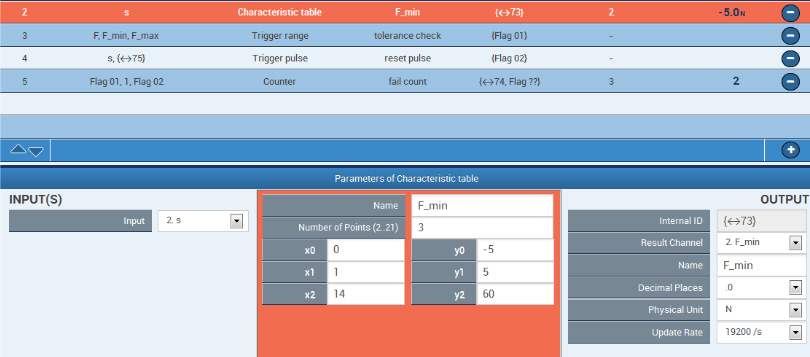

The measured force F is checked against an upper and a lower tolerance (F_max and F_min). Two value tables return tolerance values depending on the measured displacements. The diagram shows the force/time curve and the force/displacementcurve of a stroke movement with no violations of the tolerance limits.

Checking force against a tolerance band with PMX

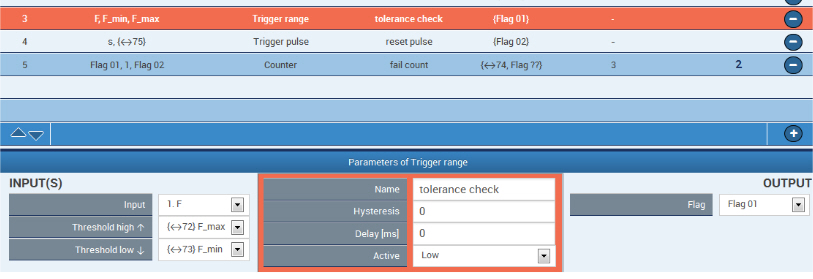

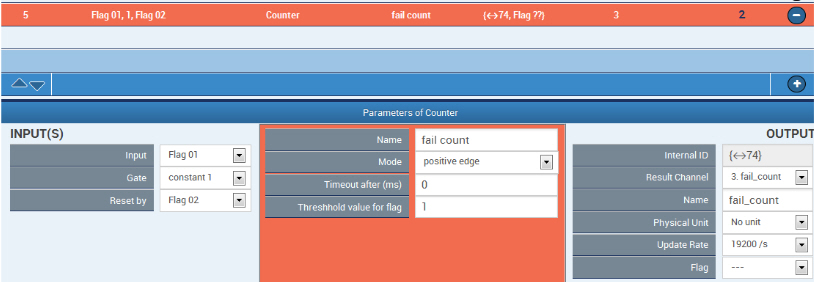

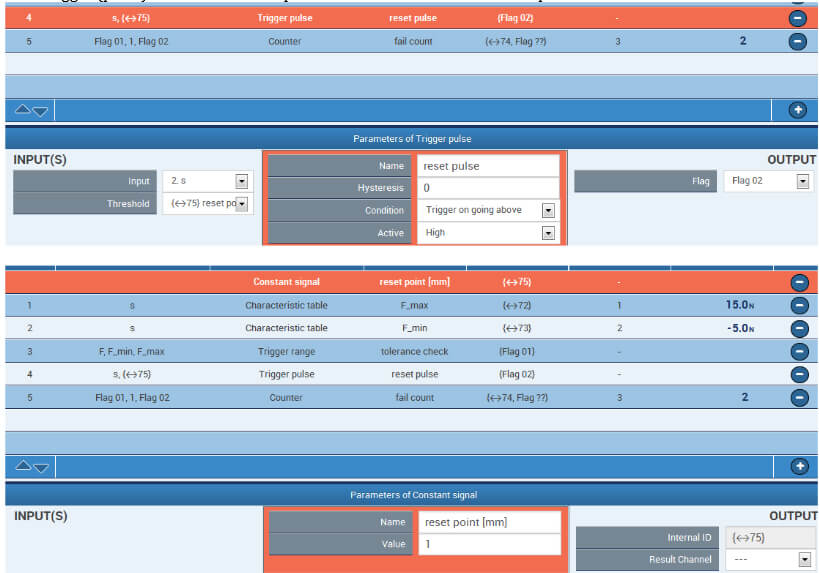

During a stroke movement with measurement of force and displacement, the force is continuously checked against a tolerance band. The tolerance limits are defined according to displacement. A counter counts the tolerance violations and a digital output reports if the counter state is greater than zero. The counter state is automatically deleted at the beginning of each stroke movement.

(The necessary glyphs are available beginning with firmware version 1.34.)

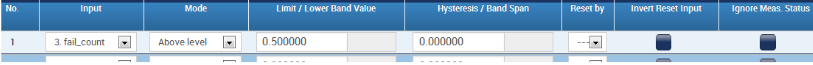

Limit switch No. 1 detects counter states >= 1:

Disclaimer

These examples are simply for the purpose of illustration. They cannot be used as the basis for any warranty or liability claims.