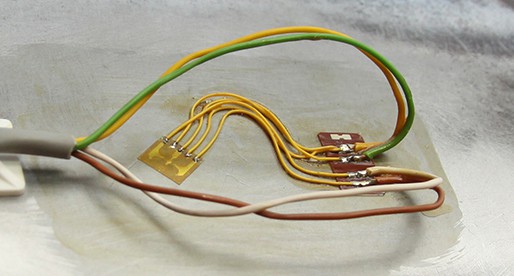

Avenue2, a consortium of Strukton and Ballast Nedam, is currently tunnelling right under Maastricht to re-route the A2 motorway. It’s a complex project, not only because the bottom of the excavation is at a depth of 22 meters below ground level, but also because of the soil characteristics and the fact that there are blocks of flats scarcely three metres from the edge of the digging work. To monitor 24/7 that the excavation is stable and that there is no danger of subsidence Avenue2, in collaboration with HBK, has installed strain gauges on the bottom layer of props in the excavation. These are used to measure the forces that the sheet piling exerts on the props. The soil characteristics are a major cause of uncertainty in the construction of the A2. Part of the ground along the 2.3 kilometre long route consists of weak marl. This is usually fairly firm soil, but the passive resistance of the bottom of the excavation can fall when the water tension in the marl increases. Furthermore, the marl can contain pockets of gravel that are holding water, as well as hollows (karst). If the resistance becomes too low or karst is encountered, water and soil can be flushed out via the bottom of the excavation. Subsidence can occur if action is not taken in time, with the possible consequence of damage to the excavation or surrounding buildings, or delays to the project. This is why Avenue2 has developed a system that can monitor the status of the soil in and around the excavation in real time.