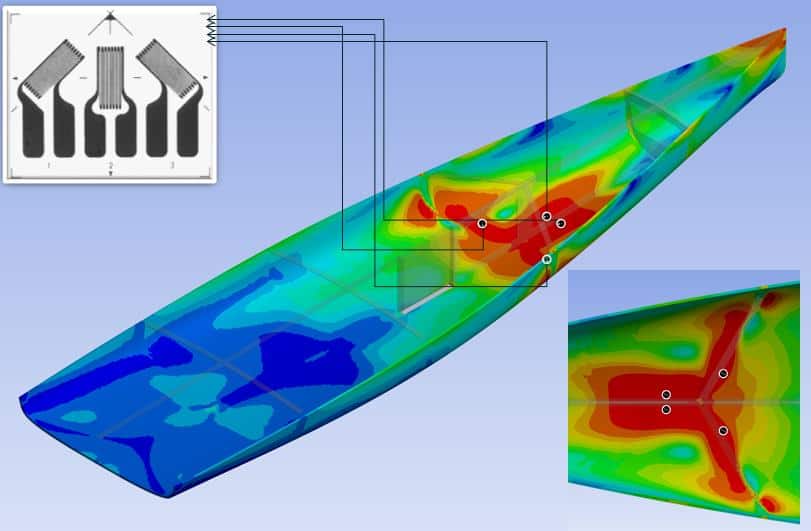

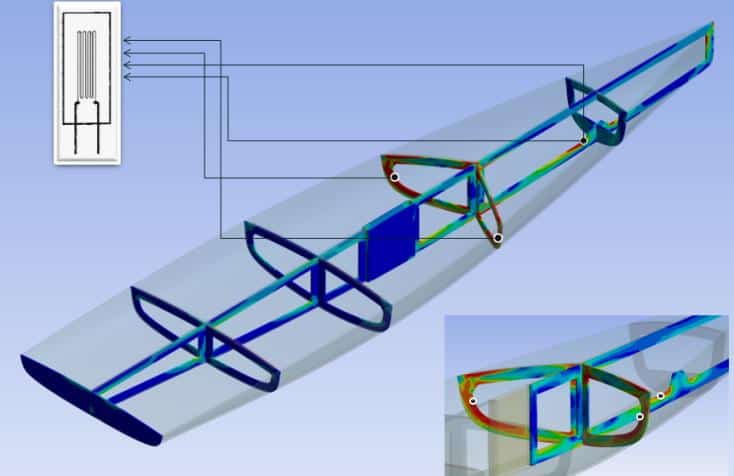

Strain Gauges

Strain gauges (often also referred to as strain gages) are the key asset for measuring fatigue and testing materials for better and safer products. Whether it is in structural durability testing, structural health monitoring, or the production of OEM transducers, HBK's optical and electrical strain gauges are the first choice.