What is the WRSGC?

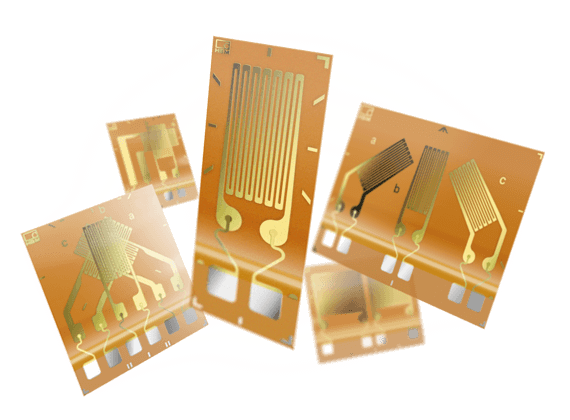

The Western Regional Strain Gage Committee is a consortium of companies and government agencies mostly from the Western United States devoted to the promotion of a free interchange of information about strain measurement techniques using strain gauges.

The Committee is a technical division of the Society for Experimental Mechanics (SEM), which was founded in 1943. The members of the WRSGC range from strain gauge, transducer and instrumentation manufacturers such as HBK, aircraft companies, national laboratories, propulsion engine manufacturers, government facilities as well as aerospace research and development firms.

Sandro Di Natale

Sandro Di Natale Malte Grieme

Malte Grieme Farnborough, UK, September 28, 2022; Tempe, AZ, USA, October 19, 2022.

Farnborough, UK, September 28, 2022; Tempe, AZ, USA, October 19, 2022. Online, October 19, 2021

Online, October 19, 2021 Online, April 20, 2021

Online, April 20, 2021 Online, October 7, 2020

Online, October 7, 2020 St. Louis, September 10, 2019

St. Louis, September 10, 2019