Easy to install, fast to develop: The SP4 footprint simplifies the construction of weighing systems

Changes can occur in the industry every day, whether through new legal requirements or because industry standards become more stringent. In many cases, developments are also based on the requests of customers who, for example, want to change their cleaning concept, adjust their nominal load or increase accuracy. As a result, engineers have to regularly review and re-design their machines and systems, as a new load cell usually requires changes to the additional space reserved for it.

As new developments always involve a lot of money, time and effort, HBK decided to strike at the root of the problem and established the SP4M footprint as an industry standard.

What does "footprint" mean?

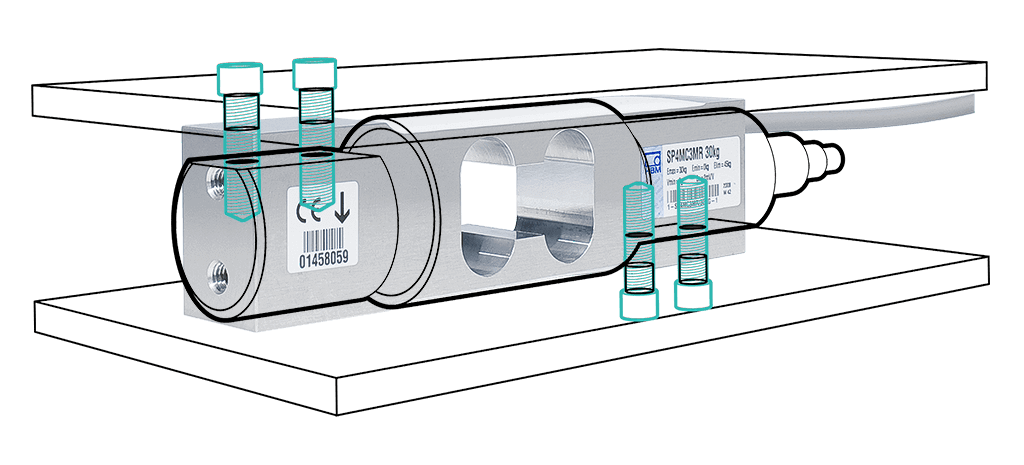

A footprint describes the dimensions of a load cell that are decisive for the installation: the dimensions of the upper and lower stop faces, the position and spacing of the threads for the screw joint and the thread sizes. For the SP4 footprint, this means 150 mm in length, 25 mm in width, six thread size M6 holes for installation, as well as another M6 thread and a fine thread for the integration of an overload stop.

"It is one of the best-selling single point load cells on the market. The load cell has been so successful that other manufacturers have also adopted the dimensions of the SP4M – and build their products accordingly to this day": Thomas Langer, International Product Manager for Weighing Technology at HBK.

HBK has established the SP4 footprint as a cross-industry standard for single point load cells. The uniform size of the load cells helps machine, scale and plant builders to remain flexible and save time and costs during development, as load cells with the same footprint can be exchanged without any design adjustments. In addition, systems can be easily upgraded with technology from HBK, the global test and measurement technology leader, as the SP4 footprint format is used by many measurement technology manufacturers in the industry.

The SP4 footprint allows easy adaptation of weighing systems to different requirements such as nominal load, degree of protection and accuracy class.

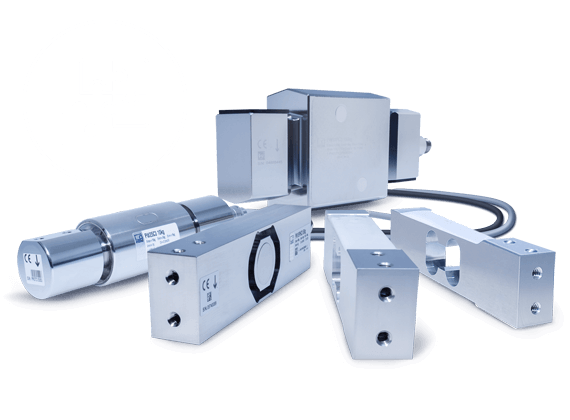

The various SP4 footprint models

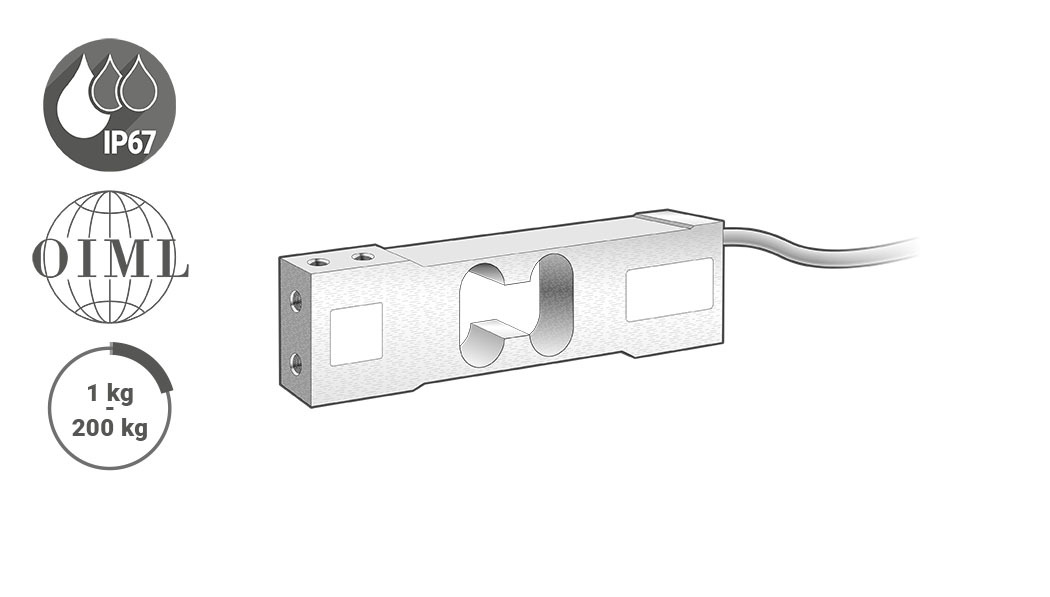

Universal: SP4M

- Maximum capacity 1 kg ... 200 kg

With its cost-effective aluminium body and an accuracy class of up to C6MR, as well as a minimum verification interval (Y) of up to 20,000, the SP4M is the first choice when a legal-for-trade single point load cell is required.

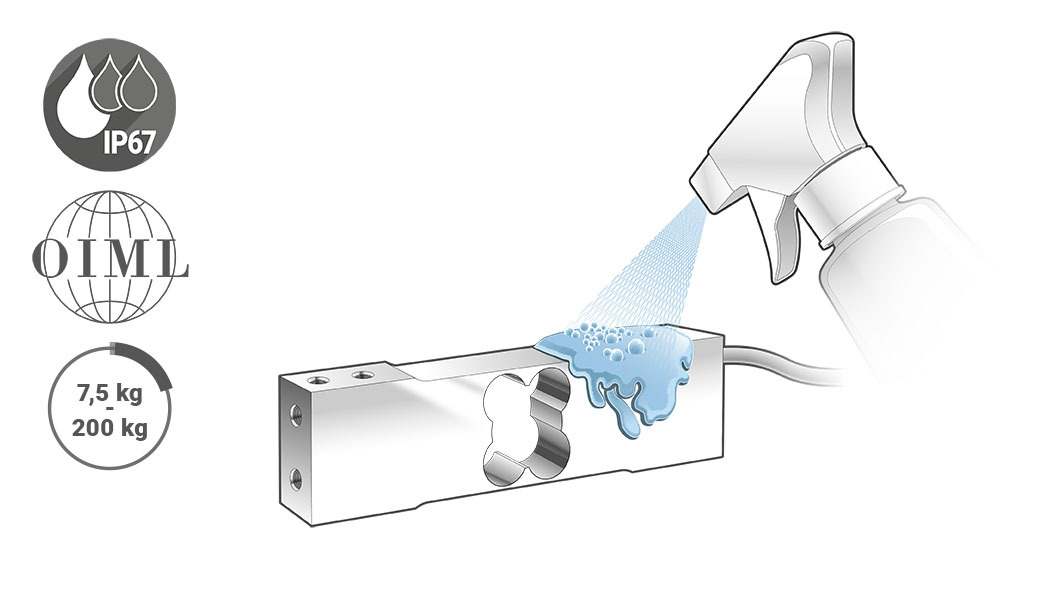

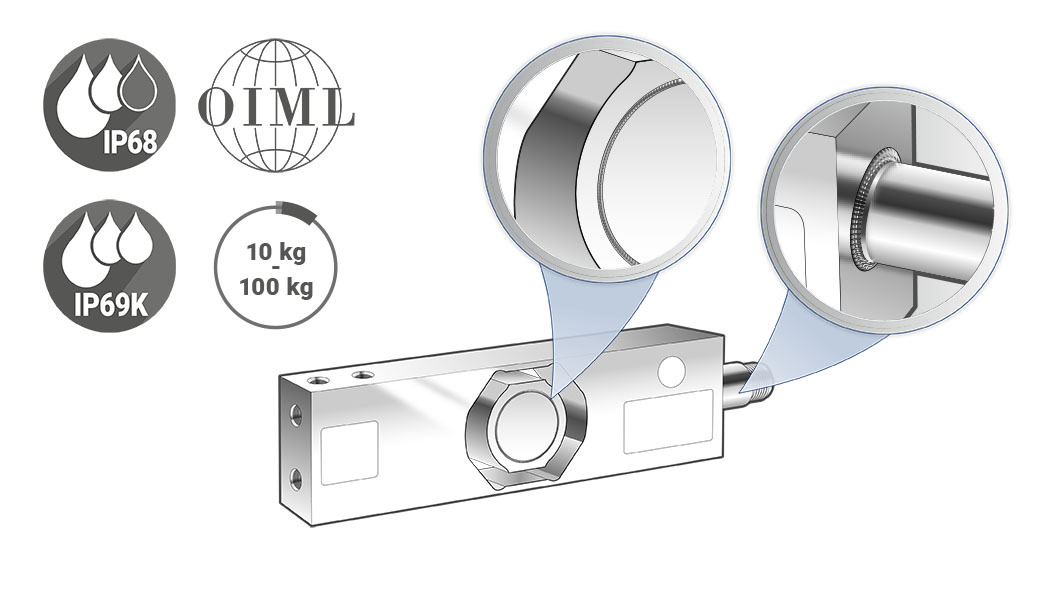

For rough use: PW15B

- Maximum capacity 7.5 kg ... 200 kg

HBK’s PW15B single point load cell has a corrosion-resistant measuring body made of 1.4545 stainless steel to withstand aggressive chemical cleaning agents in the long term.

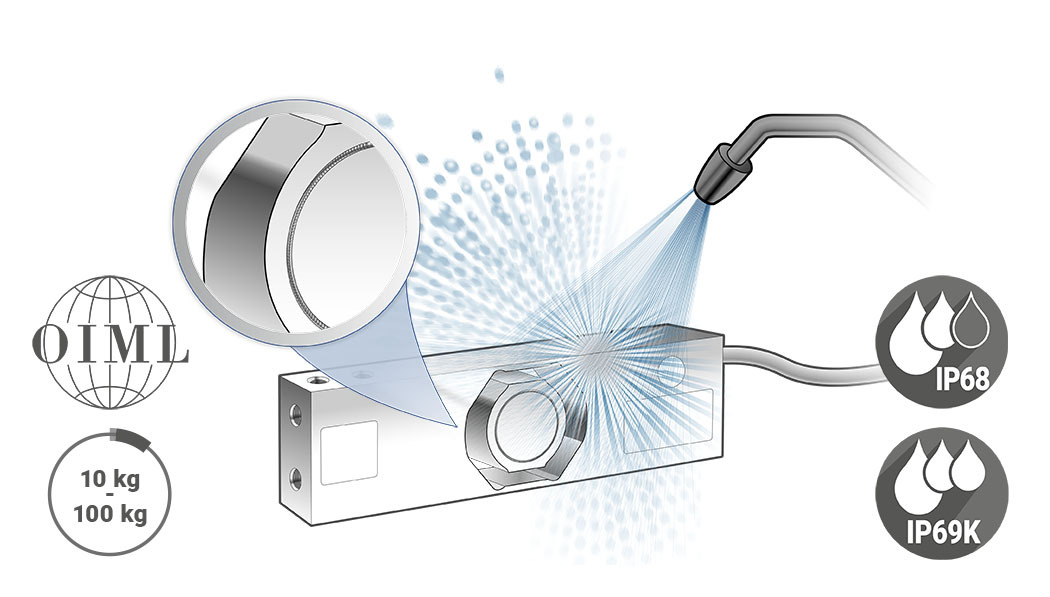

Absolutely waterproof: PW15AH

- Maximum capacity 10 kg ... 100 kg

Due to its hermetic encapsulation and IP68/IP69K degree of protection, the PW15AH can be used in harsh environments and also withstands high-pressure cleaning. HBK tests every PW15AH over 100 hours at 1 m water depth to ensure maximum quality.

Flexible and well protected: PW15PH

- Maximum capacity 10 kg ... 100 kg

The PW15PH is identical in design to the PW15AH, but due to its device plug instead of a permanently installed cable, the HBK load cell can be installed and removed quickly and easily.

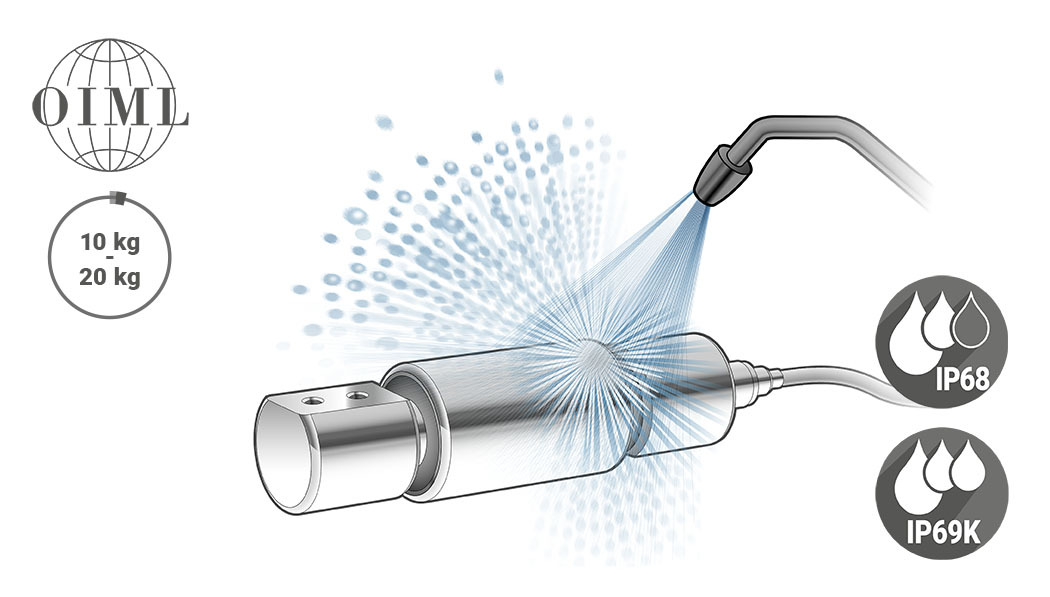

Easy to clean: PW25

- Maximum capacity 10 kg ... 20 kg

The dimensions of the "easy-to-clean” PW25 from HBK comply with the SP4 footprint. Dirt and dust cannot stick to the electropolished rounded surface, and water simply drains off, almost like the Lotus effect – ideal for high hygienic requirements.

Hygienic: PW37P

- Maximum capacity 50 kg… 200 kg

The EHEDG-certified PW37P meets the highest hygiene requirements, which is required, for example, in the food industry. Due to its particularly smooth surface (electropolished to a roughness of 0.8 μm), liquids roll right off and due to the use of 1.4545 stainless steel, the PW37P withstands aggressive cleaning agents. The optimized geometry ensures that liquids roll right off, and no dirt or product residues can accumulate.