Measures to improve EMC

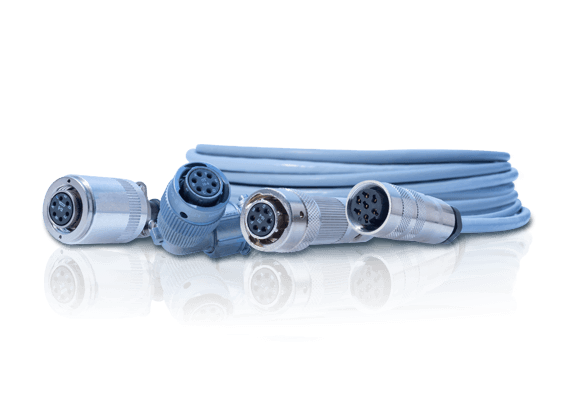

The sensor cable’s shield is galvanically connected to the sensor housing and amplifier housing, creating a Faraday cage to achieve a high standard. Therefore, all components of the measurement chain are shielded. HBM offers a double-shielded cable (type 139B), particularly immune to interference in cases where extremely strong electromagnetic fields occur.

Cable assembly requires a high standard of cleanliness and protection. Make sure to thoroughly clean the installation surfaces by removing remaining fluxing agent, safely shield the installation from high-frequency interference signals, and create proper solder joints. Detailed work specifications are provided for cable assembly to ensure full protection from electromagnetic interference and a high standard in production. Measuring leads produced in this way ensure reliable results in any environment.