Iron Bird Testing by HBM: Acquire All Data in One Sync

Digital fly-by-wire is state of the art in all modern aircraft and spacecraft. The mandatory requirement is zero fault: Malfunction during operation is by no means acceptable. Therefore, the combined functionality, performance, and reliability of flight control, digital network buses, and electrical or hydraulic actuators need to be thoroughly tested from component-level to full-scale under all possible flight conditions.

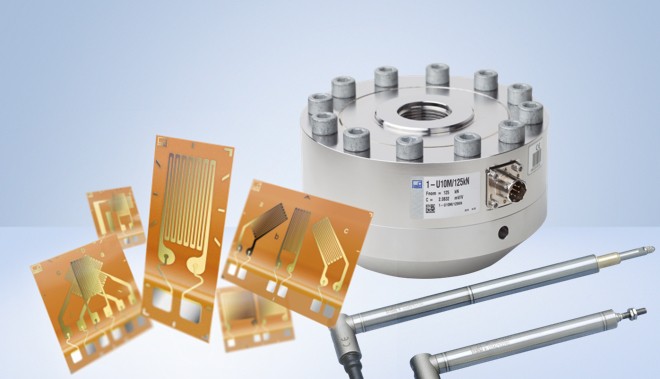

Full-scale iron bird testing is impressive: A mock-up of all the above listed components of the entire aircraft or spacecraft is placed on a giant test rig, the iron bird, making sure that the distances between the components correspond to the actual vehicle to be built. Digital avionics bus data like the common ARINC429 or MIL-STD-1553, but also others, such as ARINC664P7 (AFDX®) or ARINC825 are acquired synchronously with analog sensor data like strain gauges and force transducers.

Actuators are equipped with additional sensors measuring strain, force, displacement, and inclination. All digital and analog data need to be acquired, synchronized, visualized in live displays, and stored in a single file during the “virtual flights”.

Also, data from the load control system, taking care of simulating the flight condition like aerodynamic load, is important to interpret the test. All these data help to understand the flawless functionality of the whole flight control system to get the certificate of airworthiness, but also to qualify new developments before introduction.

HBM offers a tightly integrated solution acquiring analog sensor and digital data in one go and have it in a single data file.