No waiting time:

The torque measuring shaft T210 is immediately available from stock!

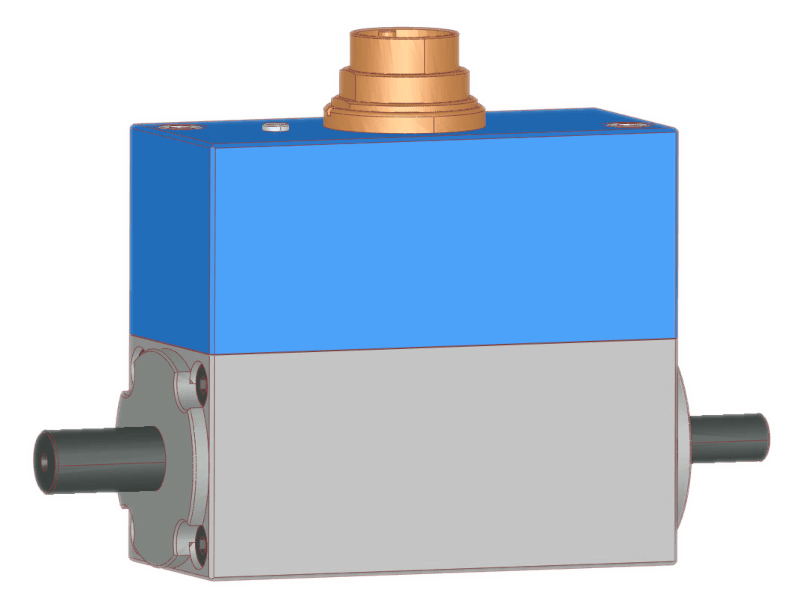

The torque transducer T210 features a precise measuring system which transmits the measurement values as well as the supply energy in a contactless way from the rotor to the stator. Additionally, the rotational speed and the angle of rotation are captured. These values are then handed over via a voltage or frequency-output. With these features the T210 shaft torque sensor is well-equipped to be used universally and is often found in End-of-Line applications or in development test benches. Finally, the round shaft ends allow for an easy and free of play integration. Thanks to its standardized design, almost all existing plants can be effortlessly retrofitted with T210.

The torque measuring shaft T210 is immediately available from stock!

Optionally available with 1024 pulses/revolution

Optionally available as a pure torque sensor without speed measurement

Torque and RPM from one device!

User-friendly integration during planning, installation and usage!

Precise and universal!

| Download the CAD step files for this product | ||

|---|---|---|

| CAD step files | ||

| Accessories CAD step files |

For more information, please refer to the data sheet or the HBMshop.

Length and width are identical for each measuring range. The height of the T210 is slightly higher – however, for most of all applications the space in this direction is not critical. The mounting hole pattern at the bottom as well as on the measuring side are identical. Though, the T210 does not feature mounting holes at the drive side.

To allow for a 1:1 replacement the diameters of the shaft ends are identical.

The frequency output (10 kHz ±5 kHz) as well as the voltage output (±10 V) basically act identical. A direct replacement should not cause challenges in most of the applications.

The measuring system now features 512 impulses per revolution.

As before there are two rectangular signals of 5 V being shifted by 90° for the measurement of the angle of rotation. Each of these signals can be used for RPM measurement. Additionally, there is a reference signal with 1 impulse per revolution allowing easier measurements at high RPM. The option to increase the signal level up to 24 V is not available anymore.

We see higher RPM, lower linearity deviation, improved temperature behavior, enlarged temperature range and an improved speed measurement system.

You tell us...