Nothing suitable for you?

If you are interested in customized optical sensors or rosettes, please contact us.

We'll be happy to advise you!

If you have any questions regarding the webinar topic or would like to be contacted by one of our technical experts, please click here.

Interested in Optical Technology? Sign up!

We keep you updated with news on HBM optical technology.

Railway Maintenance Approaches

Reacting, when limits are exceeded.

► safety: avoiding crashes and extensive damages

Reacting, before limits are exceeded.

► limit wear and tear, avoid breakdowns and unplanned down time.

Early maintenance planning; high-quality data for prognoses with low dispersion.

► action, not reaction

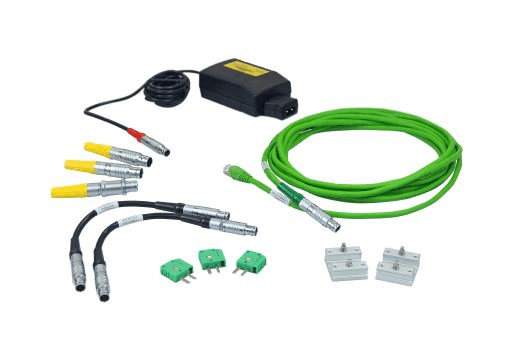

SomatXR Accessories - Test

SomatXR provides you supplementary accessories for your measurement applications and projects.

-

Rugged UPS (Uninterruptible Power Supply): UPX002

-

Multi GNSS receiver: GPS-USB-18HZ

-

Rugged quarter bridge adapter: SCM-R-SG120/350/1000

-

Rugged thermocouple adapter: SCM-R-TCK/E/J/T

-

Rugged BNC adapter: KAB430-0.3

-

Space-saving angular system cables: KAB272-W-0.2 and KAB294-W-5

-

Mounting elements, system and sensor cables, power supplies and further accessories

Questions from Webinar Participants

Optical Sensors are available with different types of cables that offer different levels of protection. Depending on the environment they will be in might require further protection. For example, on cables that are embedded in concrete it is advisable to use flexible tubes for the cable path; on cables that are deployed on a surface inside a bridge deck either a flexible tube, half a cane or a cable path tray could be fitting solutions.

This is a tricky question to answer as the type of sensors and structure to monitor will change this value. But to our experience, for a system mainly consisting of strain and temperature measurements, on a regular structure that does not require special protections, nor long distances this number would be around 60 measuring points.

The optical interrogators from HBK (DAQ) needs to be connected to a PC for configuring and data saving. There are models, however, that can be then disconnected from the PC and operate as standalone and record data internally (FS22 Static).

Check for further details on our product page FS22 Industrial BraggMETER.

No. The stated sampling rate is the same despite the number of sensors that are connected. All sensors can be acquired simultaneously and in parallel at the maximum acquisition rate.

On the QuantumX MXFS BraggMETER module, two acquiring rates will be available that can be configured by the user: 100S/S and 2000S/S. On top of the set acquisition rate, different sampling rates can be defined on the device by down sampling.

The acquisition rate defines the sweeping speed of the laser as per each sample one complete sweep on the overall wavelength spectrum is needed.

The sampling rate corresponds to the number of samples that are made available which is also user definable.

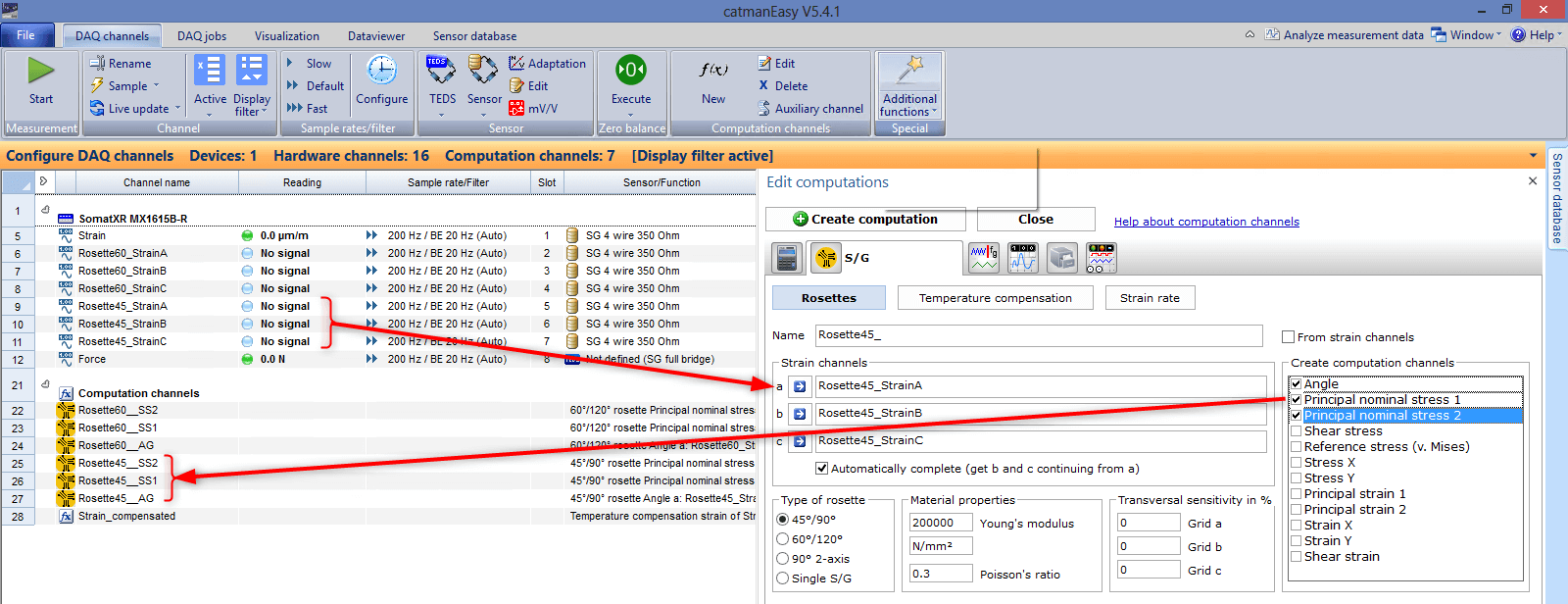

At the moment, QuantumX MXFS is compatible with catman AP but not with catman Enterprise. Please contact HBM if you have the need for this compatibility.

Catman 5.4.1 is the first version of catman that supports the QuantumX MXFS optical interrogator.

The QuantumX MXFS is compatible with FBG based sensors from any supplier, as long as these are not based on special FBG’s (example: phase-shifted FBG, long period FBG…).

It measures peaks with different reflectivities, within the available dynamic range.

Sensors embedded in concrete do need special care during installation namely because:

- Sensors have to be installed at a late stage of the construction works on the structure (as close as possible to the concreting operation) which means that they have to be installed while regular construction work is occurring and most times on critical and quite intense timing

- Sensors and cables are “fragile” elements and workers must be aware of their existence as well as be sensible to this.

- Concrete pouring is a tough process. Depending on the type of concrete and on the method used for the operation.

So, on the sensor location there are some care that can be taken to prevent damage from the whole process. For example:

- Using a tight net covering the sensor that will ensure that bigger aggregates from the concrete mixture will not hit the sensor hard

- Ensuring that the vibration process is not harming the sensors by using the vibrator at safe distances from the sensors

- Embedding the sensor location in concrete in advance to the whole operation to grant a controlled process over the sensor

On the cable paths, care must also be taken, and we always suggest the use of tubes for protecting the cables.

Attention must also be payed to the exiting of the cables from the concrete.

Again, several strategies can be used, and care is needed in all of them especially during the formwork removal to ensure that cables are not damaged with the process. A damaged cable close to the exiting from the concrete is impossible to repair...

Yes. We have teams within HBK that support the installation almost worldwide.

Yes, we have projects running in India for Structural Health Monitoring using Fiber Bragg Grating technology.

Yes, HBK currently offers off the shelf solutions based on FBG for measuring Strain, Temperature, Displacement, Tilt and Acceleration.

HBM FiberSensing supplies cables with several FBG sensors in line which can be strain sensors and/or temperature sensors.

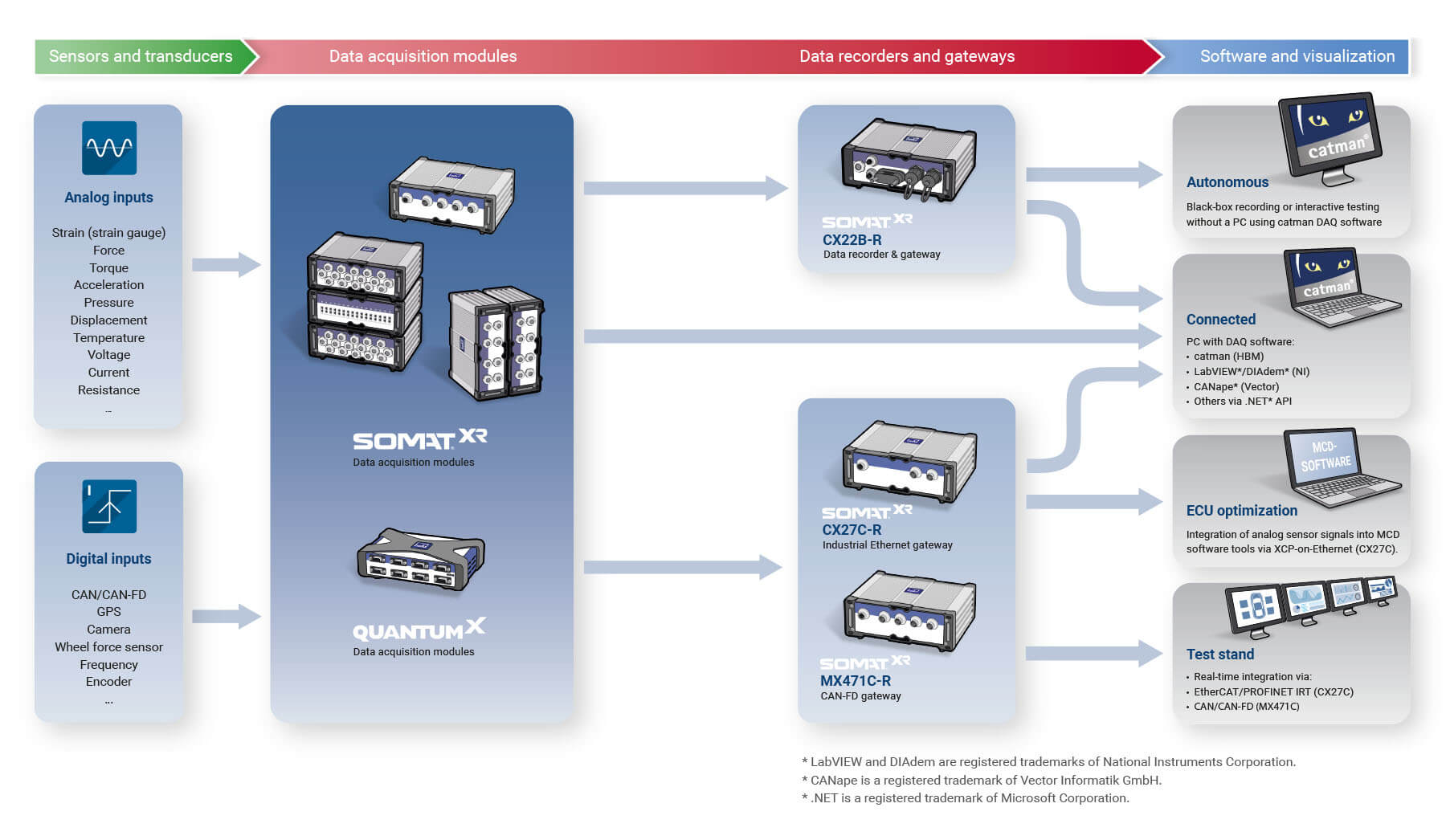

SomatXR - Your Individual Data Acquisition System

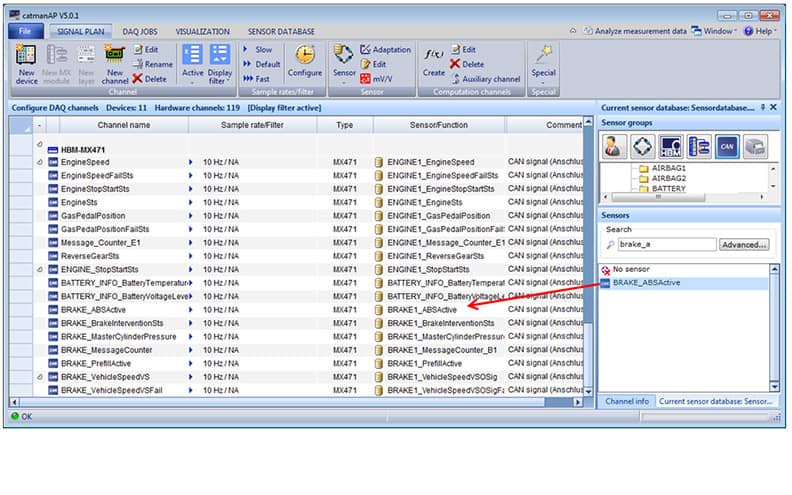

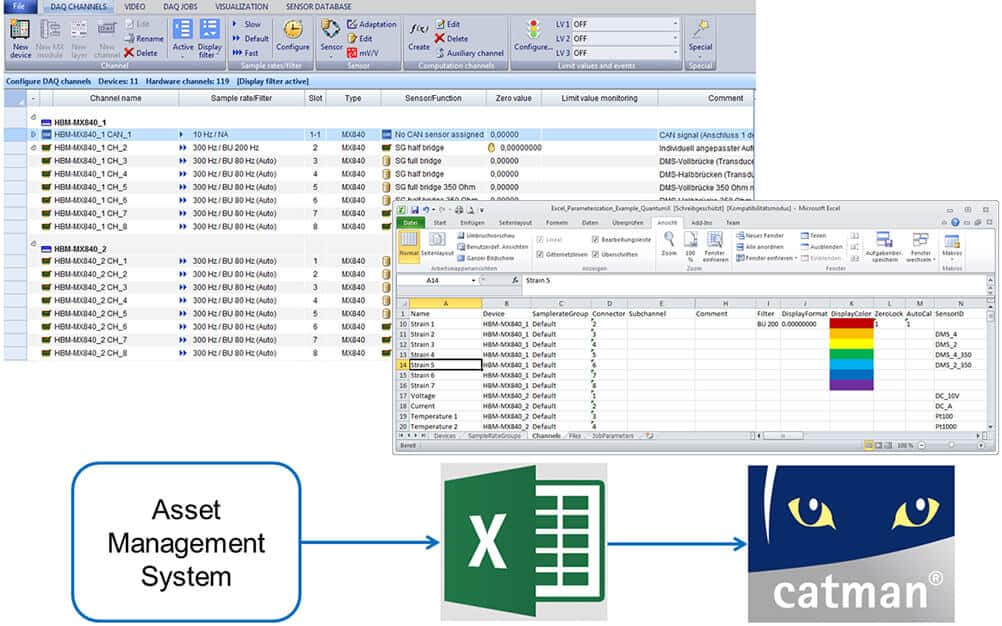

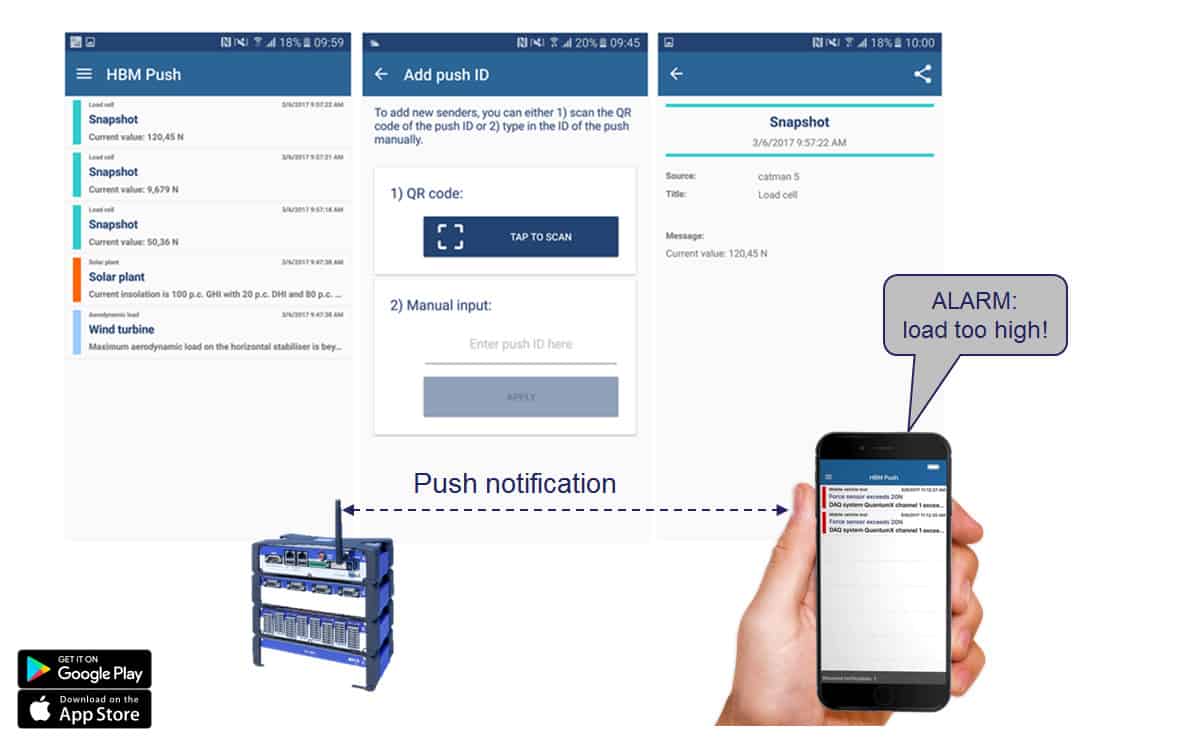

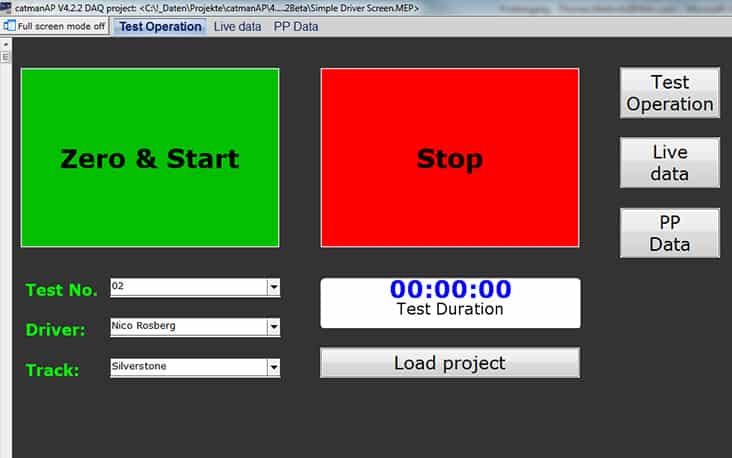

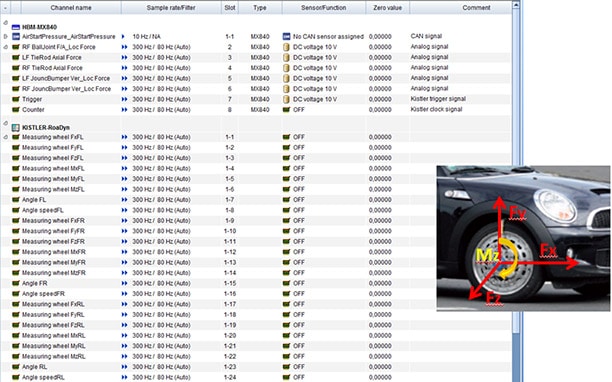

The modular architecture of the SomatXR DAQ allows you to implement your own measurement system – with a data recorder and catman DAQ software or with a connected PC and catman data acquisition software. In addition, SomatXR modules can be integrated into test bench applications or ECU optimization software in various ways and flexibly combined with QuantumX modules.

Discover the flexibility of SomatXR:

Check out all SomatXR setups.