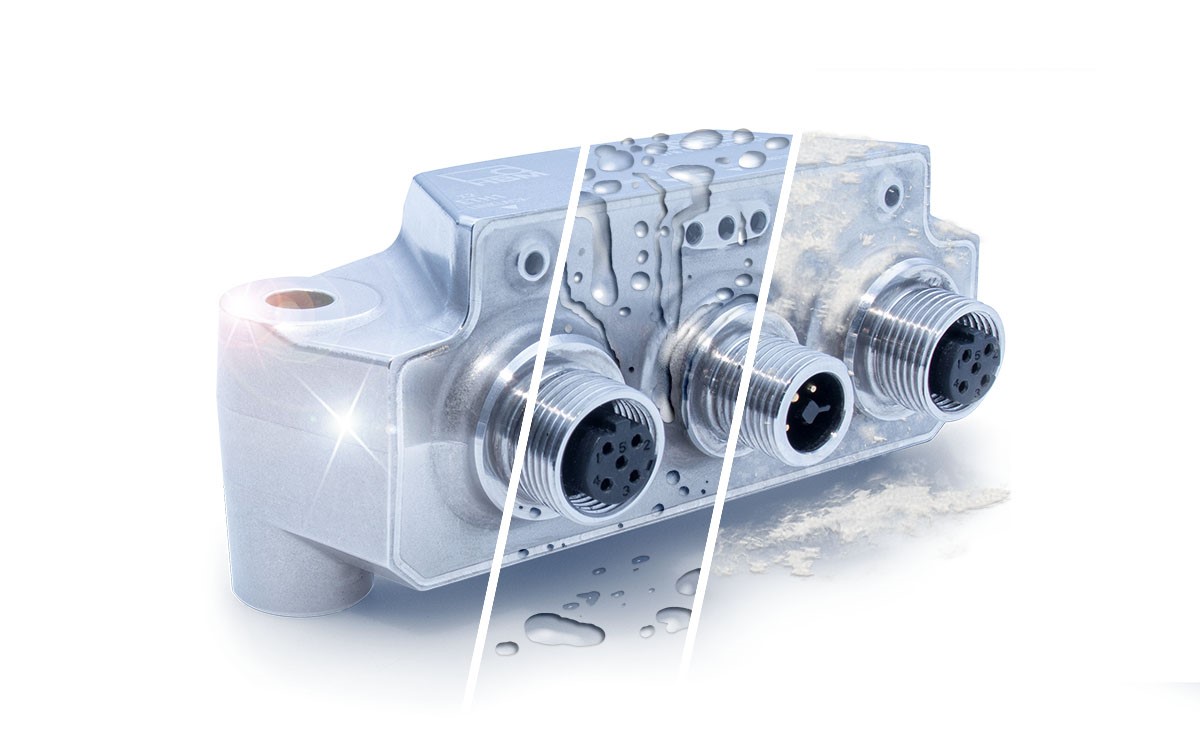

The DSE sensor electronics digitizes every analog load cell and it is extremely easy and thorough to clean it. Thomas Langer, Product Manager at HBM rightly remarks: "Due to its special design, virtually no germs or dirt can deposit on the DSE’s surface.” This feature makes it ideal to be used in aseptic filling machines. "Also, the smooth surface meets the high standards for applications in the pharmaceutical industry. In this case, DSE can help to avoid cross-contamination of various active ingredients and thus improve the safety of pharmaceutical products and drugs.

Consumers demand gently and healthily prepared food that can be stored over a long time. New technologies for the food industry, such as aseptic filling systems, allow food to be packaged almost aseptically without preservatives and heat treatment and thus, to have a shelf life of up to two years. They preserve valuable ingredients and vitamins. Hygiene is a challenge in the design of aseptic systems. To ensure that packaged foods such as milk, oils or juices do not spoil prematurely, the filling zone must be as free of micro-organisms as possible. This requires machine components, particularly easy to be cleaned thoroughly. HBM's DSE weighing electronics, designed in compliance with hygienic principles, is the ideal solution for this issue.