Invisible from the outside, indispensable on the inside: Today, sensors are at home in almost all areas of industry. In the course of digitization, they play an important role in making machines more independent and processes increasingly efficient. However, measurement technology itself must also constantly reinvent itself. The life cycles of machines and plants are long, especially in the area of weighing technology.

All You Need to Know About Digitizing Analog Load Cells

This is not only due to the components’ long service life but also to strict regulations for approval and plant manufacturers, therefore, being interested in being able to sell their plants – once approved – for as long as possible. However, digital technology is also gaining ground here. In this article, you will learn how to digitize analog load cells or replace them with digital ones.

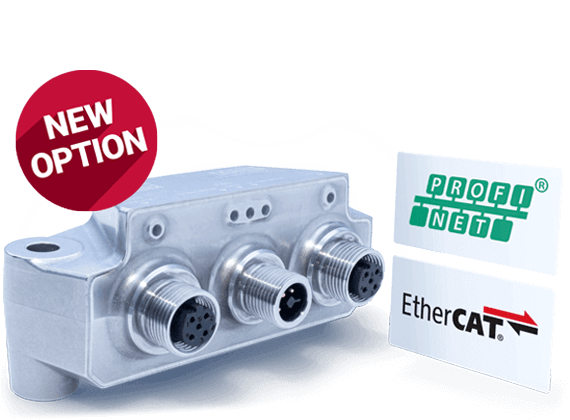

Generally, the trend toward digital sensors is noticeable across all sensor types: Whether temperature, force or torque – the digitization of sensors not only brings advantages in terms of integration into modern control systems in implementing the changeover to networked production, it also opens up new possibilities for optimizing processes such as maintenance. Instead of operators having to remember to check machines and components at regular intervals, the systems can, for example, report themselves for maintenance. Information sharing is also made easier. If desired, measurements can be obtained via a network, for instance, from portable devices such as laptops or smartphones.

Analog Signals Are More Susceptible to Interference

In the weighing technology sector, there are currently two worlds existing in parallel. On the one hand, a partly analog world that still has several years of life ahead in many production halls and, on the other hand, new digital innovations that are pushing onto the market. For instance, it is still common practice to use analog load cells in a large number of applications. Their signals are transmitted via cables, even over long distances, and then digitized to integrate them into the higher-level control system.

However, such measurement chains have a significant disadvantage compared to more up-to-date, digital solutions: The measuring signals are susceptible to interference, especially at the beginning of the measuring chain, in direct proximity to the sensor. Thus, a low-quality cable or a cable that is too long may already cause falsified measured values. However, environmental conditions such as temperature fluctuations or electromagnetic radiation can also negatively affect the signals.