BORBET has specialized in high-quality aluminum wheels with fascinating design. The family-run business was founded in 1881 and has been producing light-alloy wheels since 1977 supplying renowned automotive companies. BORBET produces aluminum wheels that enable the passion for driving to be experienced all over the world. Visit the BORBET website

BORBET: Aluminum alloy wheels - tested with QuantumX MX410 data acquisition modules

Shorter development times - this is the aim of all technology companies worldwide. BORBET, the world's leading manufacturer of aluminum wheels shows how it is done: Using a smart system of efficient tests. Always on board: HBM measurement technology - for example, the highly dynamic QuantumX MX410 measuring amplifier.

Aluminum wheels have a noble look, whether they have sporty, dynamic or classical appearance. Optical tuning of a car is emotional, it expresses passion, enthusiasm and pride, i.e. the owner's personal style.

BORBET's range of products comprises about 2,000 different light-alloy variants, with new designs being added all the time. That is exactly where a major advantage of aluminum wheels is found. Design creativity is only limited by size specifications. The size of the brake that is built in, the offset of the OEM wheel as well as the rolling circumference of OEM tires determine the lower limit. They are predefined, since tachometers and sensors have been adapted to these parameters. In between, aesthetic dreams become true, because the aluminum casting method enables optics and function to be substantially better matched than with steel wheels.

Mathematics and rigid testing make beauty safe

It goes without saying that the delicate looking aluminum version needs to be as reliable and sturdy and to withstand the same loads as its more rugged looking relative made of steel.

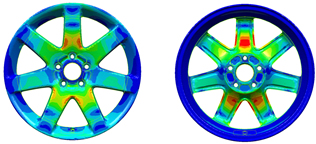

First of all, a wheel is a safety component. Technical know-how, mathematics, physics and extensive strength tests turn creative design into "safe beauties". Developers simulate the newly designed wheel using the finite element method (FEM), a recognized calculation method in solid-state simulation.

Computations are based on Hooke's Law. It describes the relationship between the acting force and the resulting deformation in a solid's elastic range. When a force acts on an elastic body, it is either extended or shortened, with mechanical stress occurring in the material.

In a solid's elastic range, this relationship is linear, i.e. occurring mechanical stress is directly dependent on the material-specific modulus of elasticity and the strain. The modulus of elasticity or Young's modulus is a constant that specifies how easy or hard it is to elastically deform a material. Young's modulus for aluminum alloys, for example, is 70 - 75 kN/mm² while for elastomers (rubber) it only ranges between 0.01 to 0.1 kN/mm².

Hooke's Law:

The finite element method discretizes a continuous domain into a defined/finite set of sub-domains, also called elements.

Every element is described by an equation that mathematically captures the element's mechanical facts. The elements are linked with their neighboring nodes. In other words: if a force acts on an element, it also acts, in a modified form, on the neighboring elements.

Mechanical stresses and their interaction are described at any point in the entire structure by the interplay of all element equations. The resulting structural analysis provides first information about the theoretical load profile. The points for which the maximum loading has been calculated are marked by a special color indicating potential weak spots.

Structural analysis

Tough 10,000 km correspond to 300,000 km

According to the guidelines of several German automotive manufacturers, a wheel needs to have a so-called rated lifetime of 300,000 km, which are simulated over 10,000 km during the biaxial wheel test.

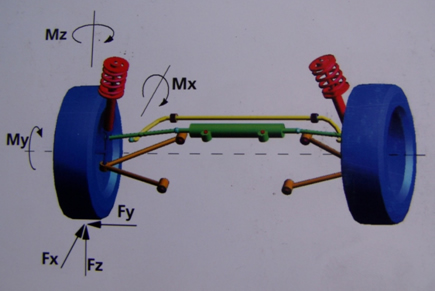

During its mileage of 300,000 km all over Europe, a wheel experiences driving conditions characterized by diverse typical stresses resulting in damage that are reproduced in a special 98-stage test cycle (Europazyklus). The wheel is subjected to these loads over about 10,000 km on the test stand, virtually in fast motion, to simulate 300,000 km on European roads and their typical conditions. Testing in the test stand significantly shortens development cycles and enables required modifications of the design or of production processes to be promptly implemented.

Forces and moments

If a front axle has a permissible static axle load of 1,000 kg this means that each wheel has a static load capacity of 500 kg. In addition to the static load resulting from the vehicle itself a wheel needs to withstand, the dynamic forces and moments caused by driving represent the main influencing factors; these include driving straight or around curves, poor stretches of road as well as special stresses such as driving over curbstones or thresholds.

Quality assurance through fatigue testing

Biaxial wheel tests are primarily used for developing new wheels. Fatigue testing is another type of endurance testing. The forces acting on the wheel were the vertical force and the horizontal lateral force resulting from static friction of the tire when driving around a curve. The maximum bending moment is calculated from these two forces and can be used as the basis for the tests.

Depending on the type of vehicle, real bending moments for cars or vans range between 2.5 kNm and about 10 kNm. The TÜV guideline for aluminum cast car wheels requires that 200,000 load cycles at 75% bending moment and 1,800,000 load cycles at 50% bending moment need to pass the test without any cracks. After the required load cycles, the surface is inspected for cracks. Fatigue testing also assures quality in production.

Optimization for enhanced energy balance

Durability testing also involves determining potential safety margins. Testing of a wheel, as a safety component, proves its durability for the intended rated lifetime of 300,000 km (car) and, in addition, provides knowledge allowing optimization of the amounts of material for producing the wheel.

According to the principle: as strong as required, using as few material as possible. Less material, i.e. light-weight design, means less unsprung mass; the vehicle can be driven faster and, at the same time, needs less fuel. Light-weight design directly contributes to reducing emissions during driving.

Another major contribution is that aluminum is saved, because producing aluminum is very energy intensive, however the material can easily be melted down to secondary material again. Considering the many millions of wheels produced by the Borbet group every year, every gram of material saved directly contributes to saving energy and making products environmentally compatible.

Conclusion

HBM measurement technology makes a decisive contribution to bringing the aesthetics and fascinating design of aluminum wheels in line with function and safety. Local strains determined through test and measurement provide important knowledge about the durability of materials and the different stresses acting on the wheel and result in savings in material and enhanced energy efficiency.

The decision for HBM

"HBM, to me, is the leading expert in the field of measurement technology. HBM absolutely lives up to its excellent reputation on the market. We were provided with professional consulting, our questions were quickly and comprehensively answered and we efficiently found a solution that works well. The QuantumX MX410 is convenient to handle, easy to use and at the same time very powerful and compact. Of course we also use HBM strain gauges provided that our customers do not have any other requirements in their specifications."

Franz-Josef Völlmecke, Head of Borbet's Test Shop Hochsauerland

Theory and practice team up

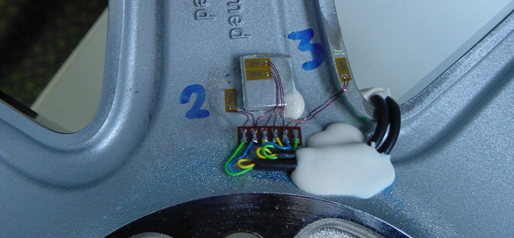

The simulation assumes favorable conditions. Subsequent practical tests investigate whether the theoretical findings can be verified by test results. For this purpose, strain gauges (SG) are installed in the area of the calculated maximum load. Strain gauges respond to tensile or compressive force with a change in electrical resistance.

Strain gauge installed on a test specimen

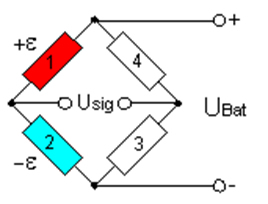

These changes are too small to allow direct analysis, therefore, strain gauges are operated in bridge circuits.

Diagram of a bridge circuit

The strain ε is calculated using the following equation:

After installation of the strain gauges, the aluminum wheels undergo fatigue testing or biaxial wheel testing. Biaxial wheel tests show the actual structural properties of newly developed wheels; biaxial wheel tests have virtually transferred the test track into the laboratory.

Since the wheels rotate in the test stands, the signals are transmitted to the QuantumX MX410 measuring amplifier via wireless telemetry. This compact, four-channel amplifier has been specially developed for acquiring and analyzing highly dynamic, mechanical processes.

Every channel of the MX410 universal module supports six transducer technologies and offers sampling rates of up to 96 kHz/channel with 24 bit resolution.

It provides the highly precise results that are required for acquiring highly dynamic forces and accelerations. The conditioned measurement signal is available as both a digital value and an analog signal. The MX410 can thus be easily connected to different analysis systems. It uses both Ethernet and FireWire for communication. Results can be recorded, visualized and analyzed on a PC using, for example, catmanAP software.