2. High-Power Traction Battery System

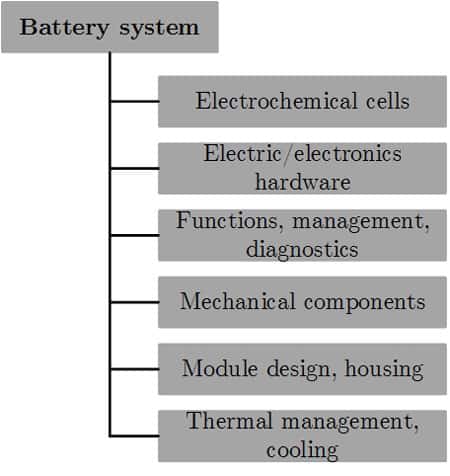

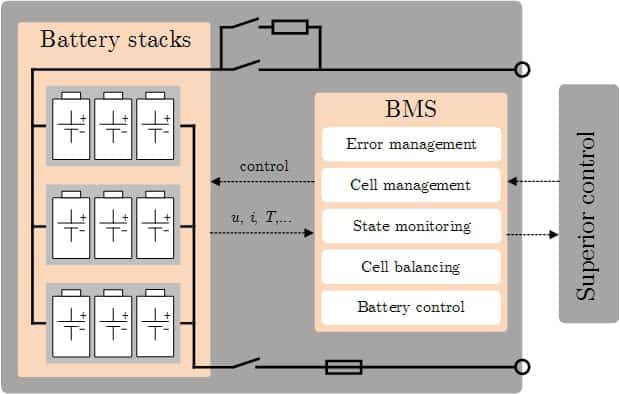

The following considerations only refer to the lithium-ion battery, because this technology has the potential to fulfil the demands of energy and power density today for its application in electric vehicles (EVs) [1]. As figures 1 and 2 reveal, a battery system consists of various complex subsystems. These individual components have to be closely coordinated with each other to guarantee a safe and optimum operation. With the interconnection of the single electrochemical cells, high system voltages and capacities can be achieved. To reach the total voltage and current requirements of the battery pack, the pack contains many discrete cells connected in series and parallel. For the application in traction batteries, the packs can contain several hundred single cells. Typically the large stack of cells is grouped into smaller stacks called modules. Within each module, the cells are welded together to complete the electrical path for the flow of current. Several of these modules are placed into the battery pack. The modules can also include cooling mechanisms, temperature monitors, and other devices like cell balancing. Cell balancing is important for the life of the battery system because without the balancing system, the individual cell voltages will drift apart over time. This result in a rapid decrease in the capacity of the total pack [2].