KY: Chaînettes de jauges pour déterminer des gradients de contrainte

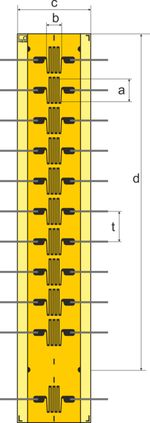

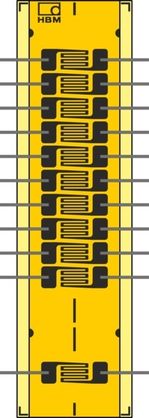

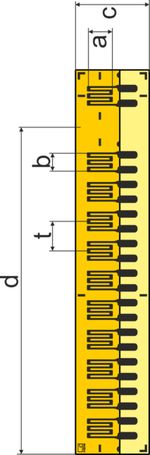

Les chaînettes de jauges de contrainte KY1, KY2, KY3, KY4, KY5, KY6, KY7, KY8 et KY9 se composent de 10 ou 15 grilles de mesure très petites, placées sur un même support à intervalle constant avec en plus une jauge de compensation. Les chaînettes sont particulièrement destinées pour déterminer des gradients de contrainte.

HBM fournit également des chaînettes de rosettes multiples et avec des grilles de mesure ayant des directions alternativement différentes, pour permettre de déterminer également des gradients de contraintes bi-axiales. Les réponses en température des chaînettes sont adaptées aux spécifications du client. L’impédance nominale des chaînettes est de 120 ohms.

Pour plus d'informations détaillées sur les chaînettes, vous pouvez vous référer à notre publication technique "An Introduction to Measurements Using Strain Gauges".

La grille de mesure est en constantan et le support des grilles est en polyimide.

Measuring grid consists of constantan, measuring grid carrier is polymide

Fast delivery for preferred strain gauge types - available from stock!

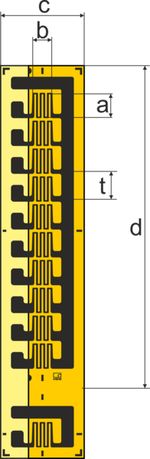

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals | Preferred types | |||||||||||

Measuring grid | Carrier | Pitch | |||||||||||||||

Ω | a | b | c | d | t | ||||||||||||

1-KY1x-1/120# | 120 | 0.6 0.024 | 1 0.039 | 7.2 0.283 | 14.5 0.571 | 1 0.039 | 2 | LS7 | 1 | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

| 1-KY1x-2/120 | 120 | 1.5 0.059 | 1.3 0.051 | 6.7 0.264 | 24.5 0.965 | 2 0.079 | 2.5 | LS7 | 1 | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

1-KY1x-4/120 | 120 | 3 0.118 | 2.1 0.083 | 9.7 0.387 | 44.5 1.752 | 4 0.157 | 5 | LS7 | 1 | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

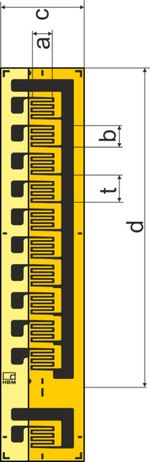

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals | Preferred types | |||||||||||

Measuring grid | Carrier | Pitch | |||||||||||||||

Ω | a | b | c | d | t | ||||||||||||

1-KY2x-1/120# | 120 | 0.8 0.031 | 0.8 0.031 | 6.9 0.272 | 15 0.591 | 1 0.039 | 1.5 | LS7 | 1 | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

1-KY2x-2/120 | 120 | 1.7 0.067 | 1.7 0.067 | 9.5 0.374 | 27 1.063 | 2 0.079 | 3.5 | LS7 | 1 | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals

| Preferred types | ||||||||||||

Measuring grid | Carrier | Pitch | ||||||||||||||||

Ω | a | b | c | d | t | |||||||||||||

1-KY3x-4/120 | 120 | 1.2 | 1.3 0.051 | 8.3 0.327 | 24 0.945 | 4 | 2.5 | LS7 | - | |||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||||||||||

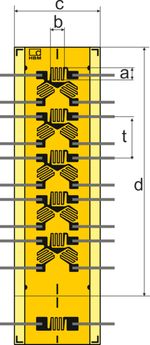

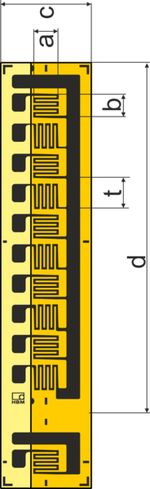

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals | Preferred types | |||||||||||

Measuring grid | Carrier | Pitch | |||||||||||||||

Ω | a | b | c | d | t | ||||||||||||

1-KY4x-2/120 | 120 | 1.2 | 1.3 0.051 | 9.2 0.362 | 24.5 0.965 | 2 0.079 | 2.5 | LS7 | - | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

1-KY4x-4/120 | 120 | 3 | 3 0.118 | 11.5 0.453 | 44.5 1.752 | 4 0.157 | 6 | LS5 | 1 | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals

| Preferred types | |||||||||||

Measuring grid | Carrier | Pitch | |||||||||||||||

Ω | a | b | c | d | t | ||||||||||||

1-KY5x-1/120# | 120 | 0.6 | 1.2 0.047 | 5.6 0.22 | 12.8 0.504 | 1 0.039 | 1.5 | - | - | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

1-KY5x-2/120 | 120 | 1.5 | 1.4 0.055 | 6 0.236 | 22.8 0.898 | 2 0.079 | 2.5 | - | - | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

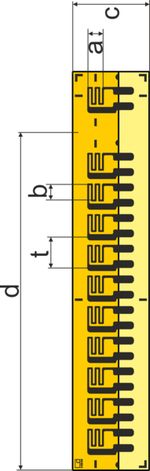

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals

| Preferred types | ||||

Measuring grid | Carrier | Pitch | ||||||||

Ω | a | b | c | d | t | |||||

1-KY6x-1/120# | 120 | 0.8 | 0.7 0.028 | 5.6 0.22 | 12.8 0.504 | 1 0.039 | 1.2 | - | - | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-KY6x-2/120 | 120 | 1.3 | 1.6 0.063 | 6 0.236 | 22.8 0.898 | 2 0.079 | 2.5 | - | - | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals

| Preferred types | ||||||||||||

Measuring grid | Carrier | Pitch | ||||||||||||||||

Ω | a | b | c | d | t | |||||||||||||

1-KY7x-2/120 | 120 | 1.3 | 1.5 0.059 | 6 0.236 | 22.8 0.898 | 2 0.079 | 2.5 | - | - | |||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||||||||||

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals

| Preferred types | ||||||||||||

Measuring grid | Carrier | Pitch | ||||||||||||||||

Ω | a | b | c | d | t | |||||||||||||

1-KY8x-2/120 | 120 | 1 | 1 0.039 | 5 0.197 | 21.7 0.854 | 2 0.079 | 2 | - | - | |||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||||||||||

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals

| Preferred types | ||||||||||||

Measuring grid | Carrier | Pitch | ||||||||||||||||

Ω | a | b | c | d | t | |||||||||||||

1-KY9x-2/120 | 120 | 1.2 | 1.2 0.047 | 5 0.197 | 21.7 0.854 | 2 0.079 | 2 | - | - | |||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||||||||||

Simplified Documentation and Parameterization

To optimize the measuring point documentation each strain gauge includes two stickers which can be placed next to the measuring point and near the measuring amplifier. Benefit from the parameter information directly in the measurement setup:

- QR code that directly links to the data sheet of the respective strain gauge

- The product and production batch numbers

- The k-factor and a additional space for your notes

- QR code containing the values of the individual strain gauge to simplify computer-aided parameterization or documentation with a scanner

Please note: newly produced strain gauges all come with the sticker in stock, strain gauges still in stock do not have this feature yet.