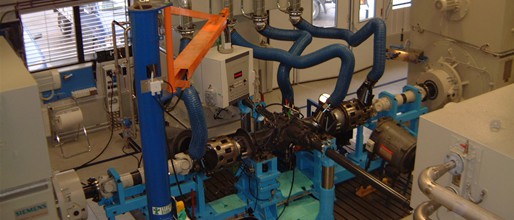

Powertrain Testing with HBM Torque Transducers

Testing of drives and power trains is a key task in vehicle development. Especially in view of the required substantial increases in efficiency next-generation cars and large utility vehicles need to offer, it is essential that every motor and every drive are precisely tested.

Torque measurement is a key criterion for measurements in the power train. Nearly all automobile manufacturers, testing houses and test stand developers worldwide rely on sensors from HBM when measuring torque. HBM's non-contacting torque transducers guarantee outstanding precision, ease of use (freedom from maintenance) and smooth integration with automation environments thanks to digital technology.

Benefit from a wide range of torque sensors suited to different requirements, up to maximum precision, maximum rotational speed and maximum speed. The ideal complement: The modules of HBM's QuantumX universal amplifier system, for precise and reliable data acquisition.