KY: ひずみグラディアント確認用のKYひずみゲージチェーン

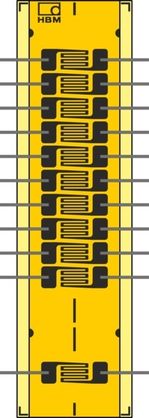

チェーンタイプのひずみゲージ(SG)のKY1、KY2、KY3、KY4、KY5、KY6、KY7、KY8、KY9は、同一のキャリア箔上に等間隔に配置された10~15個の非常に小さい計測グリッドから構成されています。 SGチェーンはひずみグラディアント(勾配)を決定するのに特に向いています。

また、計測グリッド方向が交互に変化する複数のロゼットゲージからなるHBMのSGチェーンを使用すると、2軸のひずみ状態のグラディアント(勾配)を決定できます。 SGチェーンの温度応答は顧客仕様に対応可能です。 SGチェーンの公称(定格)抵抗値は120Ωです。

SGチェーンによる計測の詳細情報は、「An Introduction to Measurements Using Strain Gauges(ひずみゲージによる計測の入門)」を御参照ください。

計測グリッドはコンスタンタンでできており、計測グリッドを保持している材料はポリイミドです。

Measuring grid consists of constantan, measuring grid carrier is polymide

Fast delivery for preferred strain gauge types - available from stock!

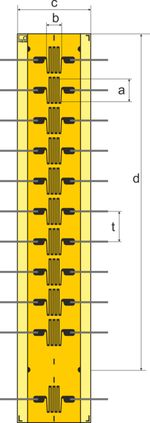

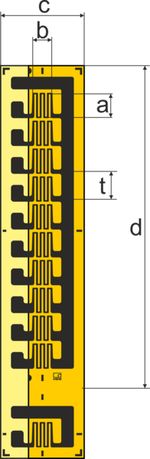

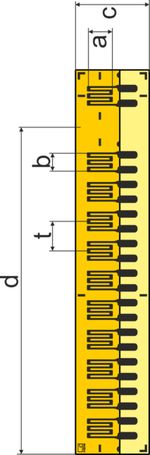

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals | Preferred types | |||||||||||

Measuring grid | Carrier | Pitch | |||||||||||||||

Ω | a | b | c | d | t | ||||||||||||

1-KY1x-1/120# | 120 | 0.6 0.024 | 1 0.039 | 7.2 0.283 | 14.5 0.571 | 1 0.039 | 2 | LS7 | 1 | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

| 1-KY1x-2/120 | 120 | 1.5 0.059 | 1.3 0.051 | 6.7 0.264 | 24.5 0.965 | 2 0.079 | 2.5 | LS7 | 1 | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

1-KY1x-4/120 | 120 | 3 0.118 | 2.1 0.083 | 9.7 0.387 | 44.5 1.752 | 4 0.157 | 5 | LS7 | 1 | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

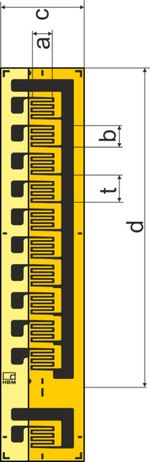

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals | Preferred types | |||||||||||

Measuring grid | Carrier | Pitch | |||||||||||||||

Ω | a | b | c | d | t | ||||||||||||

1-KY2x-1/120# | 120 | 0.8 0.031 | 0.8 0.031 | 6.9 0.272 | 15 0.591 | 1 0.039 | 1.5 | LS7 | 1 | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

1-KY2x-2/120 | 120 | 1.7 0.067 | 1.7 0.067 | 9.5 0.374 | 27 1.063 | 2 0.079 | 3.5 | LS7 | 1 | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals

| Preferred types | ||||||||||||

Measuring grid | Carrier | Pitch | ||||||||||||||||

Ω | a | b | c | d | t | |||||||||||||

1-KY3x-4/120 | 120 | 1.2 | 1.3 0.051 | 8.3 0.327 | 24 0.945 | 4 | 2.5 | LS7 | - | |||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||||||||||

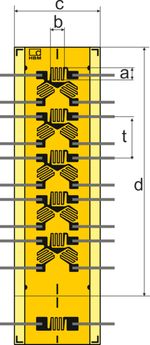

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals | Preferred types | |||||||||||

Measuring grid | Carrier | Pitch | |||||||||||||||

Ω | a | b | c | d | t | ||||||||||||

1-KY4x-2/120 | 120 | 1.2 | 1.3 0.051 | 9.2 0.362 | 24.5 0.965 | 2 0.079 | 2.5 | LS7 | - | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

1-KY4x-4/120 | 120 | 3 | 3 0.118 | 11.5 0.453 | 44.5 1.752 | 4 0.157 | 6 | LS5 | 1 | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

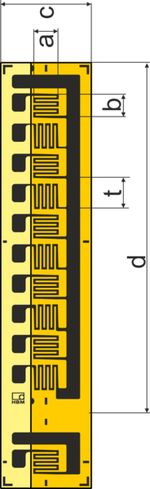

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals

| Preferred types | |||||||||||

Measuring grid | Carrier | Pitch | |||||||||||||||

Ω | a | b | c | d | t | ||||||||||||

1-KY5x-1/120# | 120 | 0.6 | 1.2 0.047 | 5.6 0.22 | 12.8 0.504 | 1 0.039 | 1.5 | - | - | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

1-KY5x-2/120 | 120 | 1.5 | 1.4 0.055 | 6 0.236 | 22.8 0.898 | 2 0.079 | 2.5 | - | - | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals

| Preferred types | |||||||||||

Measuring grid | Carrier | Pitch | |||||||||||||||

Ω | a | b | c | d | t | ||||||||||||

1-KY6x-1/120# | 120 | 0.8 | 0.7 0.028 | 5.6 0.22 | 12.8 0.504 | 1 0.039 | 1.2 | - | - | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

1-KY6x-2/120 | 120 | 1.3 | 1.6 0.063 | 6 0.236 | 22.8 0.898 | 2 0.079 | 2.5 | - | - | ||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||||||||||

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals

| Preferred types | ||||||||||||

Measuring grid | Carrier | Pitch | ||||||||||||||||

Ω | a | b | c | d | t | |||||||||||||

1-KY7x-2/120 | 120 | 1.3 | 1.5 0.059 | 6 0.236 | 22.8 0.898 | 2 0.079 | 2.5 | - | - | |||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||||||||||

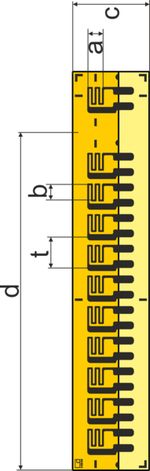

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals

| Preferred types | ||||||||||||

Measuring grid | Carrier | Pitch | ||||||||||||||||

Ω | a | b | c | d | t | |||||||||||||

1-KY8x-2/120 | 120 | 1 | 1 0.039 | 5 0.197 | 21.7 0.854 | 2 0.079 | 2 | - | - | |||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||||||||||

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Vmax | Solder terminals

| Preferred types | ||||||||||||

Measuring grid | Carrier | Pitch | ||||||||||||||||

Ω | a | b | c | d | t | |||||||||||||

1-KY9x-2/120 | 120 | 1.2 | 1.2 0.047 | 5 0.197 | 21.7 0.854 | 2 0.079 | 2 | - | - | |||||||||

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||||||||||

Simplified Documentation and Parameterization

To optimize the measuring point documentation each strain gauge includes two stickers which can be placed next to the measuring point and near the measuring amplifier. Benefit from the parameter information directly in the measurement setup:

- QR code that directly links to the data sheet of the respective strain gauge

- The product and production batch numbers

- The k-factor and a additional space for your notes

- QR code containing the values of the individual strain gauge to simplify computer-aided parameterization or documentation with a scanner

Please note: newly produced strain gauges all come with the sticker in stock, strain gauges still in stock do not have this feature yet.

技術資料ダウンロード

| タイトル/詳細 | 言語 | 製品 | 言語 | 技術資料のタイプ |

|---|---|---|---|---|

| データシート | ||||

| Dehnungsmessstreifen - Katalog | German | |||

| Strain Gauges - Catalogue | English | |||

| Тензорезисторы - катало́г | Russian | |||

| Declaration of Conformity | ||||

| Strain Gauges and Accessories - Statement of Compliance | English | |||

| Tech Notes | ||||

| Determine the thermal expansion coefficient | English | |||

| Wärmeausdehnungskoeffizient bestimmen | German | |||