2種類の抵抗値(350 Ωと1000 Ω)

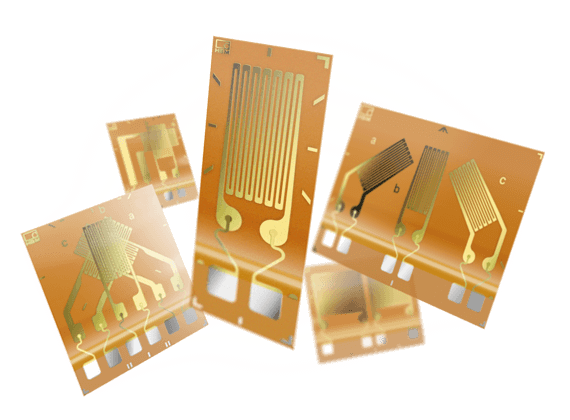

ひずみゲージMシリーズは、ファイバコンポジットなどの高い疲労強度を持つ材料のストレス分析に役立つ箔タイプのひずみゲージです。航空宇宙やスポーツ用品業界での商品開発に使用できます。

また、ひずみゲージMシリーズは、非常に広い計測温度範囲で使用できます。ひずみゲージMシリーズの疲労寿命は非常に長いので、極めて高頻繁で計測を行えます。大ひずみでもその耐久性は変わりません。形状、抵抗値、計測グリッド長などの特性を必要に合わせて組み合わせ、理想的なひずみゲージを構成できます。HBMでは36種類以上の標準ひずみゲージを提供しています。

- 温度範囲: -200 ~ +300 ℃

- 負荷サイクル: 最大1000万回 (±2000 μm/mの疲労荷重で)

- 計測グリッド長: 1.5~6 mm

We offer you foil strain gauges in various geometries and sizes, each available with temperature responses adapted to the following materials:

- Ferritic steel (10.8 ppm/K; 6.0 ppm/°F); temperature matching codes: 1

- Aluminum (23 ppm/K; 12.8 ppm/°F); temperature matching codes: 3

- Austenitic steel (16 ppm/K, 8.9 ppm/°F); temperature matching codes: 5

- Silica/composite (0,5 ppm/K; 0.3 ppm/°F); temperature matching codes: 6

- Titanium and gray cast iron (9 ppm/K; 5.0 ppm/°F); temperature matching codes: 7

Insert the temperature matching code in place of the placeholder “x” to get the ordering number of the strain gage you need.

特別なニッケル・クロム合金製の計測格子, グラスファイバで強化したフェノール樹脂製のキャリア使用

Fast delivery for preferred strain gauge types - available from stock!

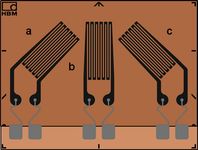

| Ordering number: | Nominal (rated) resistance | Dimensions [mm/inch] | Prefered types | |||

| Measuring grid | Carrier | ||||||

| [Ω] | a | b | c | d | |||

| 1-LM1x-1.5/350GE | 350 | 1.5 | 2.5 | 9 | 4.4 | 1 | |

| 1-LM1x-3/350GE | 350 | 3 0.118 | 3.4 0.134 | 11.8 0.465 | 5.4 0.213 | 1 | |

| 1-LM1x-6/350GE | 350 | 6 0.236 | 3.4 0.134 | 14.8 0.583 | 5.4 0.213 | 1 | |

| 1-LM1x-1.5/1K0GE | 1000 | 1.5 | 2.5 0.098 | 9 0.354 | 4.4 0.173 | 1 | |

| 1-LM1x-3/1K0GE | 1000 | 3 0.118 | 3.4 0.134 | 11.8 0.465 | 5.4 0.213 | 1 | |

| 1-LM1x-6/1K0GE | 1000 | 6 0.236 | 3.4 0.134 | 14.8 0.583 | 5.4 0.213 | 1 | |

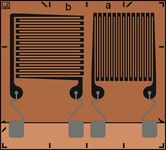

| Ordering number: | Nominal (rated) resistance | Dimensions [mm/inch] | Prefered types | |||

| Measuring grid | Carrier | ||||||

| [Ω] | a | b | c | d | |||

1-TM1x-1.5/350GE | 350 | 1.5 | 2.5 | 9.5 | 8 | 1 | |

| 1-TM1x-3/350GE | 350 | 3 0.118 | 3.4 | 11.7 0.46 | 10.6 0.417 | 1 | |

| 1-TM1x-6/350GE | 350 | 6 0.236 | 6.3 0.248 | 15 0.591 | 16.6 0.654 | 1 | |

| 1-TM1x-1.5/1K0GE | 1000 | 1.5 0.059 | 2.5 0.098 | 9.5 0.374 | 8 0.315 | 1 | |

| 1-TM1x-3/1K0GE | 1000 | 3 0.118 | 3.4 0.134 | 11.7 0.46 | 10.6 0.417 | 1 | |

| 1-TM1x-6/1K0GE | 1000 | 6 0.236 | 6.3 0.248 | 15 0.591 | 16.6 0.654 | 1 | |

| Ordering number: | Nominal (rated) resistance | Dimensions [mm/inch] | Prefered types | |||

| Measuring grid | Carrier | ||||||

| [Ω] | a | b | c | d | |||

1-TM9x-1.5/350GE | 350 | 1.5 | 2.5 | 11.3 | 7.9 | 1 | |

| 1-TM9x-3/350GE | 350 | 3 0.118 | 3.7 0.146 | 15 0.591 | 11.7 0.46 | 1 | |

| 1-TM9x-6/350GE | 350 | 6 0.236 | 3.7 0.146 | 18 0.709 | 13 0.512 | 1 | |

| 1-TM9x-1.5/1K0GE | 1000 | 1.5 0.059 | 2.5 0.098 | 11.3 0.445 | 7.9 0.311 | 1 | |

| 1-TM9x-3/1K0GE | 1000 | 3 0.118 | 3.7 0.146 | 15 0.591 | 11.7 0.46 | 1 | |

| 1-TM9x-6/1K0GE | 1000 | 6 0.236 | 3.7 0.146 | 18 0.709 | 13 0.512 | 1 | |

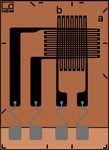

| Ordering number: | Nominal (rated) resistance | Dimensions [mm/inch] | Prefered types | |||

| Measuring grid | Carrier | ||||||

| [Ω] | a | b | c | d | |||

| 1-XM4x-1.5/350GE | 350 | 1.5 | 1.5 | 10.6 | 6 | 1 |

| 1-XM4x-3/350GE | 350 | 3 0.118 | 3 0.118 | 15 0.591 | 8.2 0.323 | 1 | |

| 1-XM4x-6/350GE | 350 | 6 0.236 | 4 0.157 | 18.6 0.732 | 12.2 0.48 | 1 | |

| 1-XM4x-1.5/1K0GE | 1000 | 1.5 0.059 | 1.5 0.059 | 10.6 0.417 | 6 0.236 | 1 | |

| 1-XM4x-3/1K0GE | 1000 | 3 0.118 | 3 0.118 | 15 | 8.2 0.323 | 1 | |

| 1-XM4x-6/1K0GE | 1000 | 6 0.236 | 4 0.157 | 18.6 0.732 | 12.2 0.48 | 1 | |

| Ordering number: | Nominal (rated) resistance | Dimensions [mm/inch] | Prefered types | |||

| Measuring grid | Carrier | ||||||

| [Ω] | a | b | c | d | |||

| 1-RM8x-1.5/350GE | 350 | 1.5 | 2.5 | 11 | 13.3 | 1 | |

| 1-RM8x-3/350GE | 350 | 3 0.118 | 3.4 0.146 | 14.6 0.575 | 18.4 0.724 | 1 | |

| 1-RM8x-6/350GE | 350 | 6 0.236 | 3.4 0.146 | 17.1 0.673 | 22.5 0.886 | 1 | |

| 1-RM8x-1.5/1K0GE | 1000 | 1.5 0.059 | 2.5 0.098 | 11 0.433 | 13.3 0.524 | 1 | |

| 1-RM8x-3/1K0GE | 1000 | 3 0.118 | 3.4 0.134 | 14.6 0.575 | 18.4 0.724 | 1 | |

| 1-RM8x-6/1K0GE | 1000 | 6 0.236 | 3.4 0.134 | 17.1 0.673 | 22.5 0.886 | 1 | |

| Ordering number: | Nominal (rated) resistance | Dimensions [mm/inch] | Prefered types | |||

| Measuring grid | Carrier | ||||||

| [Ω] | a | b | c | d | |||

| 1-RM9x-1.5/350GE | 350 | 1.5 | 2.5 | 11.3 | 11.1 | 1 | |

| 1-RM9x-3/350GE | 350 | 3 0.118 | 3.7 0.146 | 15 0.591 | 16 0.63 | 1 | |

| 1-RM9x-6/350GE | 350 | 6 0.236 | 3.7 0.146 | 18 0.709 | 16 0.63 | 1 | |

| 1-RM9x-1.5/1K0GE | 1000 | 1.5 0.059 | 2.5 0.098 | 11.3 0.445 | 11.1 0.437 | 1 | |

| 1-RM9x-3/1K0GE | 1000 | 3 0.118 | 3.7 0.146 | 15 0.591 | 16 0.63 | 1 | |

1-RM9x-6/1K0GE | 1000 | 6 0.236 | 3.7 0.146 | 18 0.709 | 16 0.63 | 1 | |

Simplified Documentation and Parameterization

To optimize the measuring point documentation each strain gauge includes two stickers which can be placed next to the measuring point and near the measuring amplifier. Benefit from the parameter information directly in the measurement setup:

- QR code that directly links to the data sheet of the respective strain gauge

- The product and production batch numbers

- The k-factor and a additional space for your notes

- QR code containing the values of the individual strain gauge to simplify computer-aided parameterization or documentation with a scanner

Please note: newly produced strain gauges all come with the sticker in stock, strain gauges still in stock do not have this feature yet.

技術資料ダウンロード

| タイトル/詳細 | 言語 | 製品 | 言語 | 技術資料のタイプ |

|---|---|---|---|---|

| データシート | ||||

| Dehnungsmessstreifen - Katalog | German | |||

| Strain Gauges - Catalogue | English | |||

| Тензорезисторы - катало́г | Russian | |||

| Declaration of Conformity | ||||

| Strain Gauges and Accessories - Statement of Compliance | English | |||