Foil strain gauges are used to determine the value and direction of strain. This is achieved by a measuring grid that is usually installed on a material surface to acquire applied strain as a factor of changes in electrical resistance against the foil strain gauge’s nominal resistance and its sensitivity factor. It registers compression as a decrease in electrical resistance and elongation as an increase.

To calculate material stresses (Experimental stress analysis) the strain values are coupled with a material’s physical properties such as its Young’s modulus (Hooke’s law).

Alternate applications for strain gauges are transducers such as load cells, force-, torque- and pressure transducers.

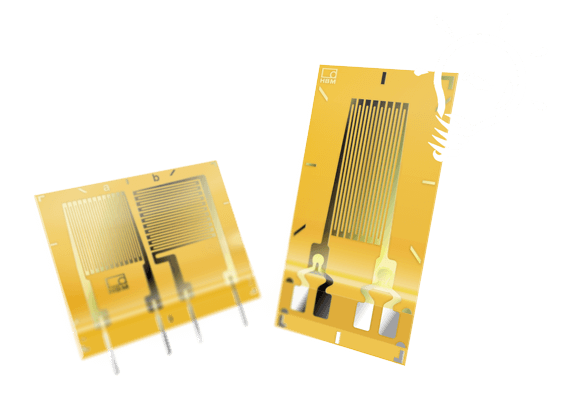

There are thousands of distinct foil strain gauges available from HBM including linear, rosette, torsion/shear, full bridge, and chain formats.

- Linear strain gauges are preferable for measuring strain across a single plane of direction

- Rosette foil strain gauges feature dual measuring grids to offset strain measurements at a 90° angle to measure biaxial stress

- Torsion/shear strain gauges feature uniquely arranged measuring grids for determining the shear stress of torsion bars

- Double linear foil strain gauges feature parallel measuring grids for acquiring perpendicular stress in bending beams

- Full bridge strain gauges feature 4 integrated measuring grids for robust strain measurements of shear stresses in tension and compression bars

- Chain foil strain gauges are equipped with a number of smaller measuring grids to acquire shear force gradients across the measuring bridge