Force transducers, or force sensors, differ from load cells in one important aspect: While load cells are installed in the weighing scale before the scale’s calibration, a force sensor is calibrated immediately after production and the result is recorded in the accompanying documents.

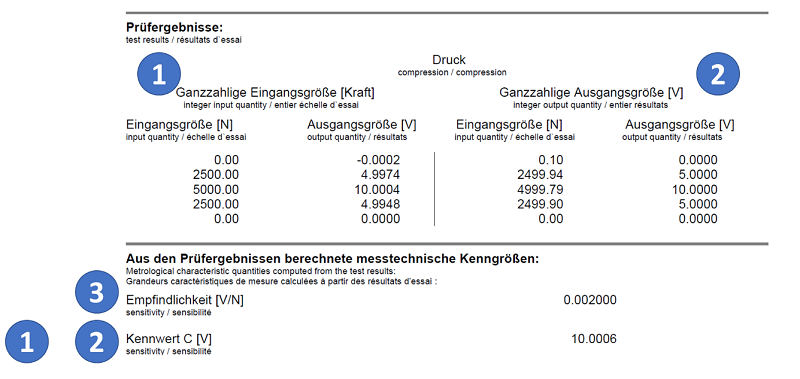

The requirement for the force transducer is, therefore, to reliably maintain the sensitivity that is determined during its calibration in the factory when used. To achieve this, the sensor must be mounted correctly. Correctly adjusting the measuring amplifier is also a very important step in the commissioning of each force sensor. This step, the so-called adjustment, ensures that the output signal of the force sensor can be interpreted correctly by your measuring amplifier system or software so that you obtain correctly measured values at the end of the day.

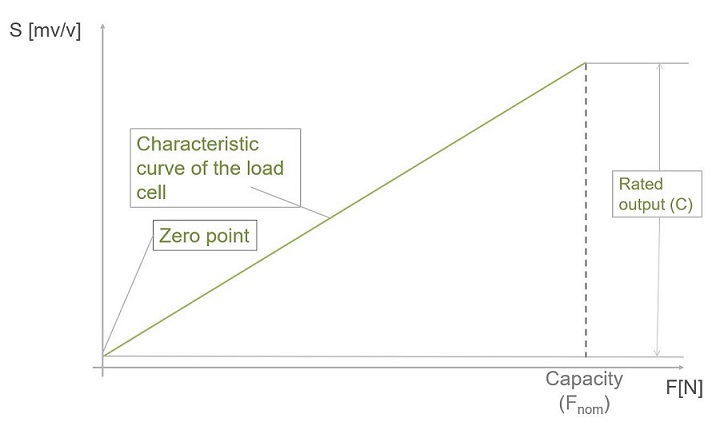

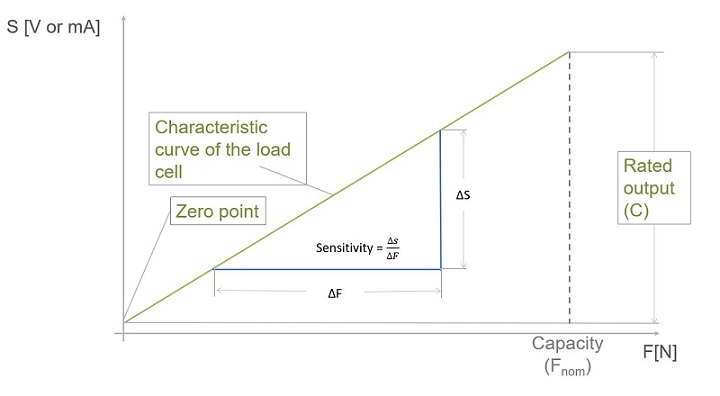

The Characteristic Curve of a Force Transducer

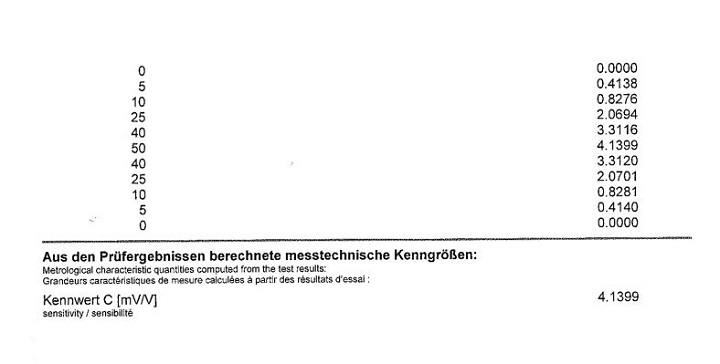

The result of the calibration measurement during production is documented and provided along with the force transducer; at HBM, this document is referred to as the "test record". The test record specifies the so-called rated output (symbol C) and has the unit mV/V.