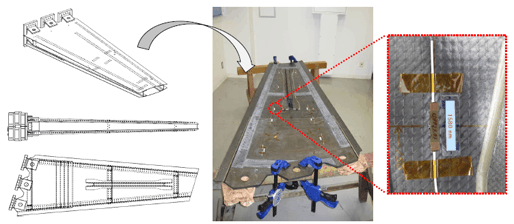

HBM’s optical strain gauge systems (Fig.3) were first used to undertake the structural testing of the ATD’s canard wing design by applying variable loads to the wing using a hydraulic actuator. One of the aims of the project was to monitor the effects of impact damage on the canard wing using 18-channel optical strain gauges (Fig.4). Researchers are also focusing on the development of a Health Monitoring System (HMS) for new wing structures using optical strain gauges.

[image missing]

Fig.4 Monitoring example of impact level and location

The decision to utilize optical strain gages, as opposed to mechanical devices, was to minimize the possibility of any risk of explosion while ensuring that electromagnetic effect (EME) concerns did not impact on the results. A total of 20 optical strain gages were distributed on the wing to give the coverage needed for the stress calculations (Fig.5).

[image missing]

Fig.5 Monitoring display of strain value and estimated strain distribution picture by pre-FEA results

Researchers working on the project were able to save a significant amount of time in fitting the optical strain gauges with HBM’s patch over the time taken to fit standard mechanical strain gauges. The optical strain gauges are suitable for both dynamic and static tests on the structure.

In addition researchers used HBM's MGCplus in combination with three of HBM’s DI410 optical strain gauge interrogators. These are 4-channel devices with a capacity of up to 1,000 measurements/sec. Two of HBM’s M416 multiplexers were also used for connecting up to 320 optical measuring points to provide fully synchronized measurement in real time. Data capture and analysis was carried out with HBM’s catman Enterprise software connected to all the devices.