Optical strain gauges: What you need to know

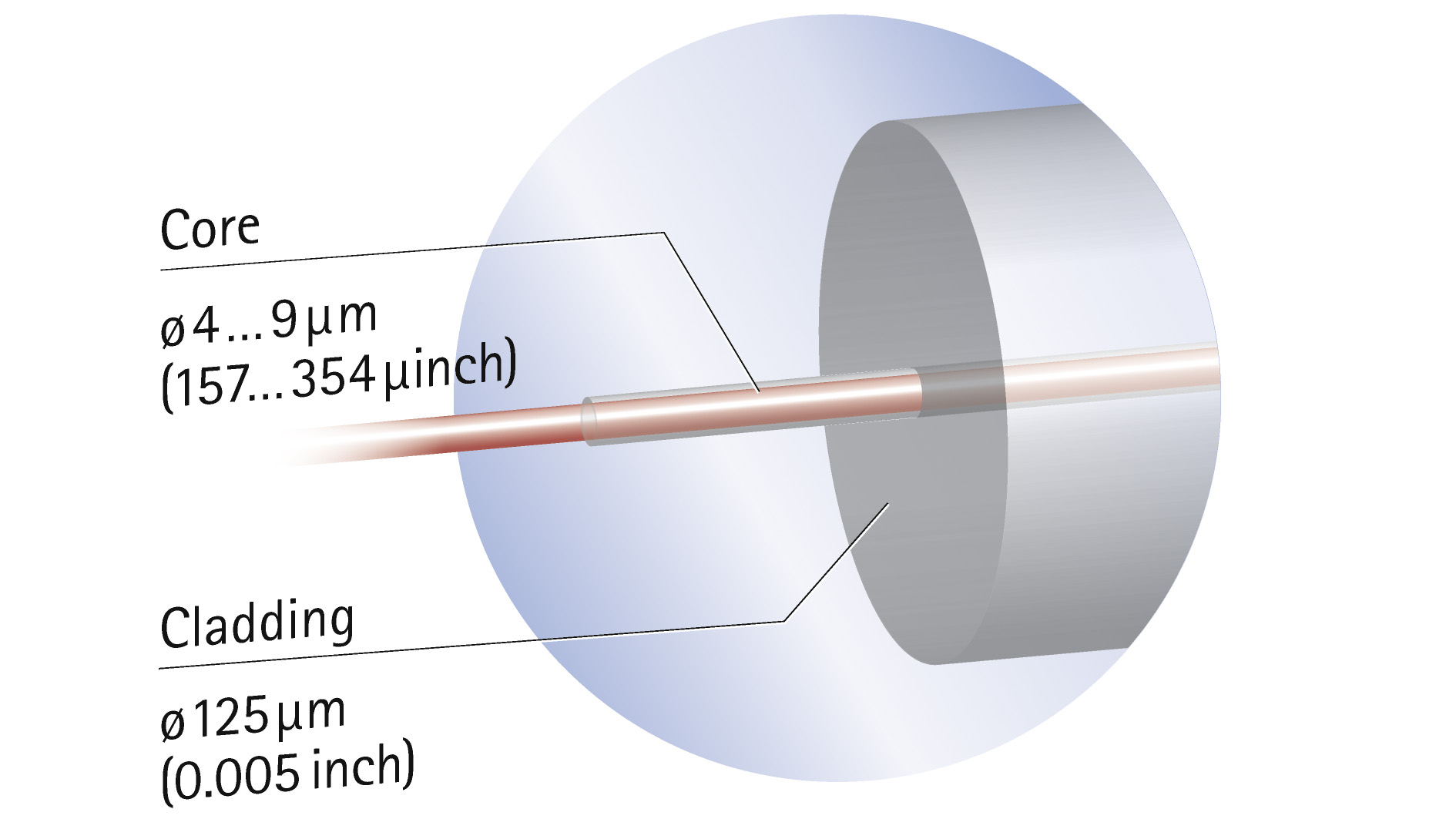

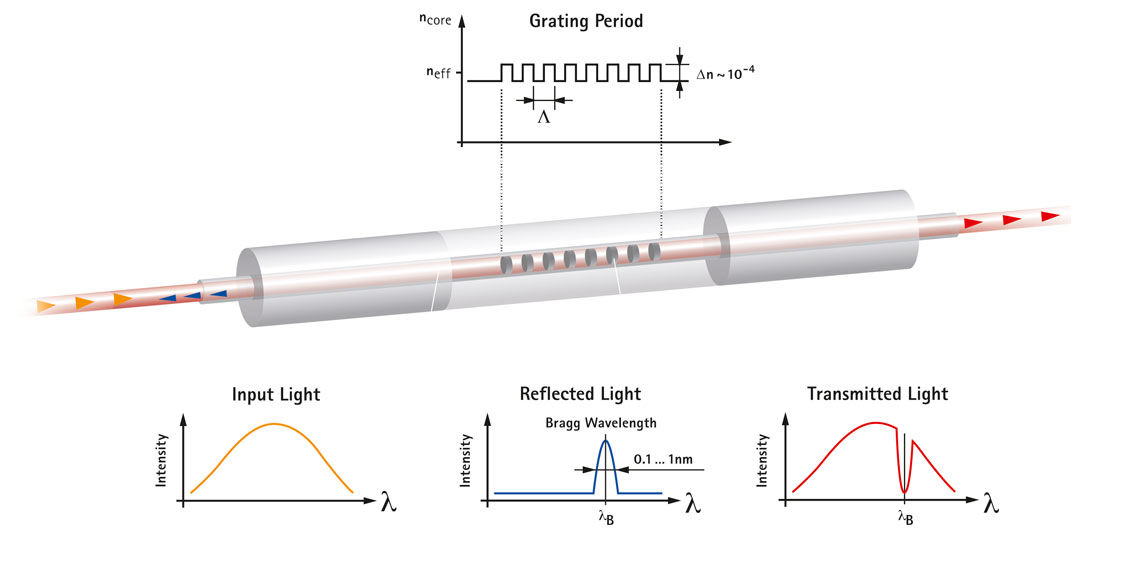

옵티컬 스트레인 게이지 (광센서 혹은 옵티컬센서 라고도 불리우는 Fiber Bragg Grating 기반의 센서)는 온도나 압력, 가속도, 변위 와 같은 다른 타입의 센서를 쉽게 통합하여 측정할 수 있습니다. 기존의 스트레인 게이지와 달리 전기가 필요없으며 광섬유를 통해 전파되는 빛을 이용하여 측정하기에 전자파 간섭의 영향을 받지 않습니다. 특정 어플리케이션에서 옵티컬 게이지가 기존 스트레인 게이지보다 측정 정확도가 뛰어난 것도 이러한 이유 때문입니다.