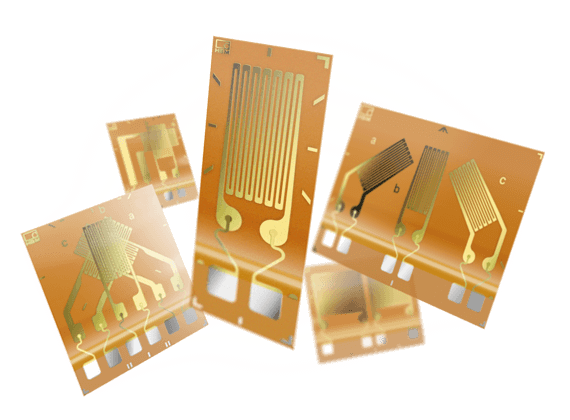

M Series Strain Gauges: For Stress Analysis of Materials with High Fatigue Strength

M series strain gauges are foil strain gauges for stress analysis of materials with high fatigue strength such as fiber composites. They can also be used in product development, for example in the aerospace or sporting goods industries.

In addition, M series strain gauges offer a very large temperature range. Due to their excellent fatigue life, M series strain gauges enable measurements to be repeated extremely frequently, also in case of high strain. Properties such as different geometries, resistance values, and measuring grid lengths can be combined to configure the ideal strain gauge—over 36 preferential strain gauges are available for immediate delivery.

- Temperature range: -200 to +300 °C

- Load cycles: Up to 10 million at +/- 2000 µm/m fatigue loading

- Measuring grid lengths: 1.5 to 6 millimeters

We offer you foil strain gauges in various geometries and sizes, each available with temperature responses adapted to the following materials:

- Ferritic steel (10.8 ppm/K; 6.0 ppm/°F); temperature matching codes: 1

- Aluminum (23 ppm/K; 12.8 ppm/°F); temperature matching codes: 3

- Austenitic steel (16 ppm/K, 8.9 ppm/°F); temperature matching codes: 5

- Silica/composite (0,5 ppm/K; 0.3 ppm/°F); temperature matching codes: 6

- Titanium and gray cast iron (9 ppm/K; 5.0 ppm/°F); temperature matching codes: 7

Insert the temperature matching code in place of the placeholder “x” to get the ordering number of the strain gage you need.

Measuring grid consists of special nickel-chromium alloy, measuring grid carrier is made of glass-fiber reinforced phenolic resin

Fast delivery for preferred strain gauge types - available from stock!

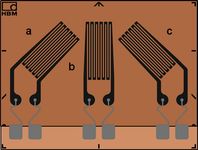

| Ordering number: | Nominal (rated) resistance | Dimensions [mm/inch] | Prefered types | |||

| Measuring grid | Carrier | ||||||

| [Ω] | a | b | c | d | |||

| 1-LM1x-1.5/350GE | 350 | 1.5 | 2.5 | 9 | 4.4 | 1 | |

| 1-LM1x-3/350GE | 350 | 3 0.118 | 3.4 0.134 | 11.8 0.465 | 5.4 0.213 | 1 | |

| 1-LM1x-6/350GE | 350 | 6 0.236 | 3.4 0.134 | 14.8 0.583 | 5.4 0.213 | 1 | |

| 1-LM1x-1.5/1K0GE | 1000 | 1.5 | 2.5 0.098 | 9 0.354 | 4.4 0.173 | 1 | |

| 1-LM1x-3/1K0GE | 1000 | 3 0.118 | 3.4 0.134 | 11.8 0.465 | 5.4 0.213 | 1 | |

| 1-LM1x-6/1K0GE | 1000 | 6 0.236 | 3.4 0.134 | 14.8 0.583 | 5.4 0.213 | 1 | |

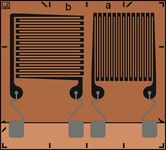

| Ordering number: | Nominal (rated) resistance | Dimensions [mm/inch] | Prefered types | |||

| Measuring grid | Carrier | ||||||

| [Ω] | a | b | c | d | |||

1-TM1x-1.5/350GE | 350 | 1.5 | 2.5 | 9.5 | 8 | 1 | |

| 1-TM1x-3/350GE | 350 | 3 0.118 | 3.4 | 11.7 0.46 | 10.6 0.417 | 1 | |

| 1-TM1x-6/350GE | 350 | 6 0.236 | 6.3 0.248 | 15 0.591 | 16.6 0.654 | 1 | |

| 1-TM1x-1.5/1K0GE | 1000 | 1.5 0.059 | 2.5 0.098 | 9.5 0.374 | 8 0.315 | 1 | |

| 1-TM1x-3/1K0GE | 1000 | 3 0.118 | 3.4 0.134 | 11.7 0.46 | 10.6 0.417 | 1 | |

| 1-TM1x-6/1K0GE | 1000 | 6 0.236 | 6.3 0.248 | 15 0.591 | 16.6 0.654 | 1 | |

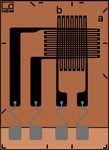

| Ordering number: | Nominal (rated) resistance | Dimensions [mm/inch] | Prefered types | |||

| Measuring grid | Carrier | ||||||

| [Ω] | a | b | c | d | |||

1-TM9x-1.5/350GE | 350 | 1.5 | 2.5 | 11.3 | 7.9 | 1 | |

| 1-TM9x-3/350GE | 350 | 3 0.118 | 3.7 0.146 | 15 0.591 | 11.7 0.46 | 1 | |

| 1-TM9x-6/350GE | 350 | 6 0.236 | 3.7 0.146 | 18 0.709 | 13 0.512 | 1 | |

| 1-TM9x-1.5/1K0GE | 1000 | 1.5 0.059 | 2.5 0.098 | 11.3 0.445 | 7.9 0.311 | 1 | |

| 1-TM9x-3/1K0GE | 1000 | 3 0.118 | 3.7 0.146 | 15 0.591 | 11.7 0.46 | 1 | |

| 1-TM9x-6/1K0GE | 1000 | 6 0.236 | 3.7 0.146 | 18 0.709 | 13 0.512 | 1 | |

| Ordering number: | Nominal (rated) resistance | Dimensions [mm/inch] | Prefered types | |||

| Measuring grid | Carrier | ||||||

| [Ω] | a | b | c | d | |||

| 1-XM4x-1.5/350GE | 350 | 1.5 | 1.5 | 10.6 | 6 | 1 |

| 1-XM4x-3/350GE | 350 | 3 0.118 | 3 0.118 | 15 0.591 | 8.2 0.323 | 1 | |

| 1-XM4x-6/350GE | 350 | 6 0.236 | 4 0.157 | 18.6 0.732 | 12.2 0.48 | 1 | |

| 1-XM4x-1.5/1K0GE | 1000 | 1.5 0.059 | 1.5 0.059 | 10.6 0.417 | 6 0.236 | 1 | |

| 1-XM4x-3/1K0GE | 1000 | 3 0.118 | 3 0.118 | 15 | 8.2 0.323 | 1 | |

| 1-XM4x-6/1K0GE | 1000 | 6 0.236 | 4 0.157 | 18.6 0.732 | 12.2 0.48 | 1 | |

| Ordering number: | Nominal (rated) resistance | Dimensions [mm/inch] | Prefered types | |||

| Measuring grid | Carrier | ||||||

| [Ω] | a | b | c | d | |||

| 1-RM8x-1.5/350GE | 350 | 1.5 | 2.5 | 11 | 13.3 | 1 | |

| 1-RM8x-3/350GE | 350 | 3 0.118 | 3.4 0.146 | 14.6 0.575 | 18.4 0.724 | 1 | |

| 1-RM8x-6/350GE | 350 | 6 0.236 | 3.4 0.146 | 17.1 0.673 | 22.5 0.886 | 1 | |

| 1-RM8x-1.5/1K0GE | 1000 | 1.5 0.059 | 2.5 0.098 | 11 0.433 | 13.3 0.524 | 1 | |

| 1-RM8x-3/1K0GE | 1000 | 3 0.118 | 3.4 0.134 | 14.6 0.575 | 18.4 0.724 | 1 | |

| 1-RM8x-6/1K0GE | 1000 | 6 0.236 | 3.4 0.134 | 17.1 0.673 | 22.5 0.886 | 1 | |

| Ordering number: | Nominal (rated) resistance | Dimensions [mm/inch] | Prefered types | |||

| Measuring grid | Carrier | ||||||

| [Ω] | a | b | c | d | |||

| 1-RM9x-1.5/350GE | 350 | 1.5 | 2.5 | 11.3 | 11.1 | 1 | |

| 1-RM9x-3/350GE | 350 | 3 0.118 | 3.7 0.146 | 15 0.591 | 16 0.63 | 1 | |

| 1-RM9x-6/350GE | 350 | 6 0.236 | 3.7 0.146 | 18 0.709 | 16 0.63 | 1 | |

| 1-RM9x-1.5/1K0GE | 1000 | 1.5 0.059 | 2.5 0.098 | 11.3 0.445 | 11.1 0.437 | 1 | |

| 1-RM9x-3/1K0GE | 1000 | 3 0.118 | 3.7 0.146 | 15 0.591 | 16 0.63 | 1 | |

1-RM9x-6/1K0GE | 1000 | 6 0.236 | 3.7 0.146 | 18 0.709 | 16 0.63 | 1 | |

Simplified Documentation and Parameterization

To optimize the measuring point documentation each strain gauge includes two stickers which can be placed next to the measuring point and near the measuring amplifier. Benefit from the parameter information directly in the measurement setup:

- QR code that directly links to the data sheet of the respective strain gauge

- The product and production batch numbers

- The k-factor and a additional space for your notes

- QR code containing the values of the individual strain gauge to simplify computer-aided parameterization or documentation with a scanner

Please note: newly produced strain gauges all come with the sticker in stock, strain gauges still in stock do not have this feature yet.

Product Literature

| Title / Description | Language | Products | Language | Content Types |

|---|---|---|---|---|

| Data Sheets | ||||

| Dehnungsmessstreifen - Katalog | German | |||

| Strain Gauges - Catalogue | English | |||

| Тензорезисторы - катало́г | Russian | |||

| Declaration of Conformity | ||||

| Strain Gauges and Accessories - Statement of Compliance | English | |||