Metal foil-type strain gauges are widely used as the main sensing principle in force, torque and pressure measurements. The vast majority of force transducers, load cells, torque transducers and ultra-high pressure transducers are based on this design and are available in a wide variety of measuring bodies.

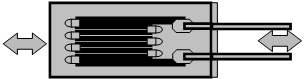

All foil-type strain gauges are based on a common principle; they use positive or negative strain to convert mechanical changes into electrical signals. In dedicated spots on the spring body, where high strain occurs under load, four strain gauges – two under positive and two under negative strain – are typically connected in a Wheatstone bridge circuit. This "double voltage divider“ with changing resistances opposite to one another, so the output voltage is nearly proportional to the deformation of the spring body.

Fig. 1. Strain gauges are connected to a Wheatstone bridge circuit to give a voltage output that enables any deformation to be easily measured.

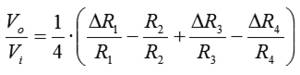

The output signal is given as a ratio between the voltage supply and the output voltage. It is calculated as follows:

Foil-type strain gauge transducers are the most accurate for determining mechanical quantities. At the same time they are the best choice to provide lowest uncertainties.

The principles of strain gauge operation are well established, meaning that full focus can be maintained on the measuring task.

Unlike many other pick-up principles, foil-type strain gauges can be built for nearly unlimited high nominal loads simply by scaling up the measuring body. Examples are force transducers in MN range, torque trasducers in MNm range and ultra-high pressure transducers in GPa range (7).

If at the same time dynamics are important, strain zones have to be designed as small as possible ensuring high stiffness (4)(5)(6).

In other applications, such as pressure transducers measuring hydrostatic pressure, there are more choices than for other mechanical quantities. Lower pressure applications, which account for the largest segment of this market, usually use capacitive or piezo-resistive MEMS solutions, especially for measurement of low pressures of a few bars. Overload resistance is particularly important for measuring high pressures that effectively excludes capacitive and piezo-resistive MEMS solutions – despite some progress with newer designs in recent years.

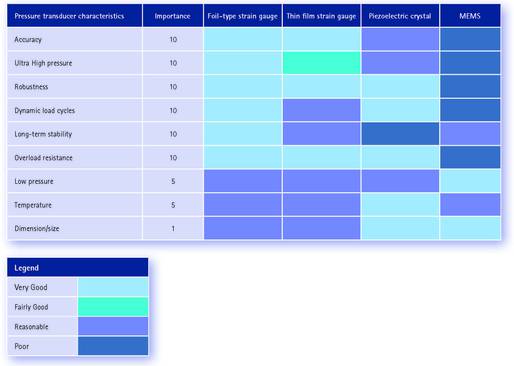

Figure 2 provides a comparison of the different types of strain gauge technologies and their suitability in pressure measurement from a number of different perspectives.

Figure 2: Comparison of different pressure measurement technologies (8)

Examining this table reveals that strain gauge based ultra-high pressure transducers are the primary choice for measurements where very high accuracy and long term stability are needed. This is especially relevant when comparing the results of various national metrology institutes in different counties (9).

It is possible to undertake a similar analysis of the different principles for every other measurable quantity. This is best when trying to design a measuring chain optimized for a particular measuring task since the selected pick-up principle is an important interface to the process or phenomena being investigated.