Introduction

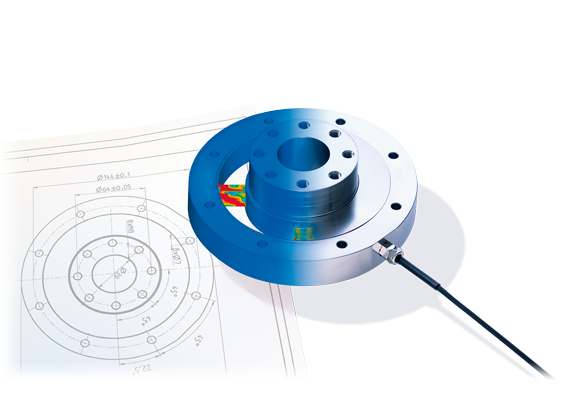

HBM provides custom-engineered solutions for a wide variety of OEM applications that have a unique and demanding need to measure load, force, pressure, weight, or torque including strain gauges for custom transducer manufacturers. HBM also offers OEM gauging services through customer-supplied parts. This paper will explain the process behind a customdesigned sensor solution from initial scope to perfor mance definition, through the design and build cycle, to verification and validation. The basics of a strain gauge based custom sensor design will be explained as well as how HBM engineers create a high-performance sensor

that fits the customer’s equipment, rather than forcing the equipment to fit the sensor.

HBM has more than 60 years in the measuring, testing, analysis, and custom sensor industry. The company provides OEM sensors to industries such as automotive, aerospace, agriculture, heavy equipment, on- and off-highway vehicles, civil engineering, energy, process weighing, and medical.

A successful project track for an OEM process begins within the first 30 days when the customer and HBM have an introductory web conference to cover the scope of the project including obstacles that might be presented. Then, HBM engineers complete an initial concept drawing, perform FEA analysis, and submit the specs to the customer for review. Modification or approval of concept drawings is finalized and a quotation for prototypes and production is submitted. From there, the prototypes are built at HBM’s Marlboro, MA location. The prototypes are fully tested and validated and are then shipped to the customer for their own testing and validation.