Weighing Technology Solutions for Wind Turbines: Cost-Effective Planning and Reduced Downtimes

The past several years have seen two major trends in wind energy development:

- A migration from onshore to offshore wind parks

- The development of increasingly large structures that are needed in offshore operational conditions to meet the demand for vastly improved energy generation efficiency.

These developments make reliably weighing certain wind turbine components indispensable. Precise weighing is a prerequisite for determining the structural support components’ overall weight and cost-effectively planning logistical processes. Costly downtimes can be prevented through the precise weighing and optimization of critical components such as rotor blades and gears.

HBM provides weighing technology solutions for the following applications

One-Stop Service for the Weighing of Wind Turbine Structures

Weighing of rotor blades

Weighing of gears

One-Stop Service Provider for Weighing Wind Turbine Structures

A frequent challenge that wind turbine operators have to face is the requirement to determine the structural support components’ overall weight of so delays can be minimized and costs significantly reduced. Adequate support equipment, such as cranes and transport vessels, which is a significant cost factor, needs to be allocated prior to installation. However, the structural support components of a series can substantially vary in terms of weight due to manufacturing tolerances. Hence, the weight cannot be determined through calculation using, for instance, the Finite Element Method.

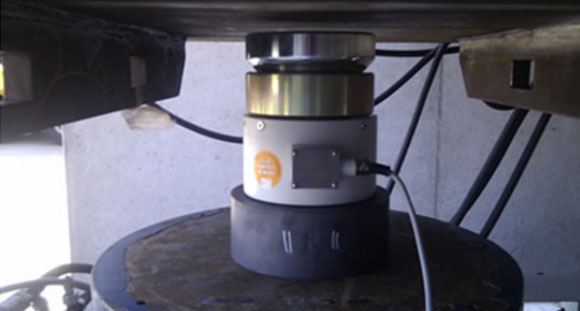

HBM is a one-stop service provider for weighing offshore wind turbines and often uses C18 reference compressive force transducers with up to 5 MN capacity per sensor. These force transducers offer excellent repeatability and are optionally available with a Class 0.5 DAkkS calibration certificate as perISO 376:201. Alternatively, extremely compact type C6A force transducers can also be used. These are designed for handling compressive forces up to 2 MN. These transducers are suitable for utilization in harsh environments. They are maintenance-free and can even be installed in difficult-to-access areas. The service is provided on site (as fast "in-situ” weighing) and requires very little time. Additionally, HBM’s service team checks the calculations before concluding the project.

HBM has been deeply involved in wind projects for fifteen years and has been a key partner in some 20 large-scale projects over that period. Alpha Ventus, Germany’s first wind park, comprised six wind turbines constructed with a jacket structure and another six wind turbines with a Tripod structure. HBM was a key participant in the initial FINO and RAVE research within the Alpha Ventus framework, which paved the way for Germany’s first offshore wind park.

Do you know about your support structure’s dead weight?

The HBM Services:

- Reference compressive force transducers up to 5 MN load capacity per cell

- Classification option with DKD calibration certificate per ISO376: Class 0.5

- Excellent repeatability guaranteed

Your benefits:

- Quick “in situ” weighing service for wind turbines

- Double check of your calculations

- Allocate ships and transport vessels prior to installation: Minimize delays and reduce your costs.

Balancing: Weighing of rotor blades

An imbalance in a wind turbine rotor results in eccentricity when the rotor blades are turning. If this imbalance is not rectified, it might lead to the loosening of individual parts. The rotor blades must be balanced and all of them should have the same weight. If the target weight is not attained, masses need to be added or removed. Software enables calculating this state of equilibrium.

Extremely precise load cells need to be attached to the rotor blade’s root and tip to facilitate precise weighing of the rotor blades. This requires very precise load cells. Since a measurement process can take up to two hours, load cells with an extremely low creep are required. Z7A shear beam load cells are well suited to be used in this application due to their particularly robust design. They are available with accuracy class C3 i.e. with 3000 divisions in accordance with OIML R60. The Z7A load cell is made of galvanized steel and has an IP67 degree of protection. Additionally, it has a low installation height and complies with EMC requirements as per the EN45501. Their maximum capacities range from 500 kg to 10 t.

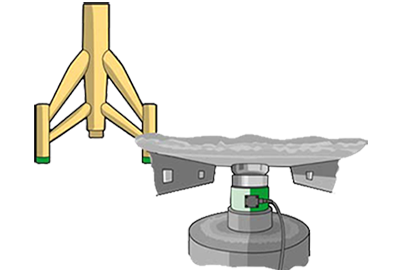

Weighing of gears, the core element of the gearbox

Wind turbine failure results in downtimes going up to several weeks and high replacement costs, especially in offshore applications. In most cases, the entire gearbox needs to be replaced. The gears are situated at the gearbox's core. Precisely manufacturing the gears is essential to the gearbox’s service life as a whole. The gears’ weight is also considered a key parameter for determining production quality. Similar to the method for support structures, gears are weighed according to the 3-point-method, which involves installing the gears on three load cells arranged at angles of 120 degrees from each other and a precision amplifier for obtaining the sum of the three partial weights.

Benefits of HBM Weighing Technology Solutions

More cost-effective logistical processes

Optimized components

Reduced downtimes

Longer service life