Adhesive bonds cannot be tested completely non-destructively. This gives motivation to permanently monitor bonded joints to record their structural condition and to ensure reliable force transmission.

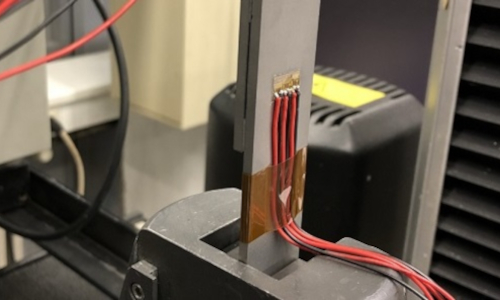

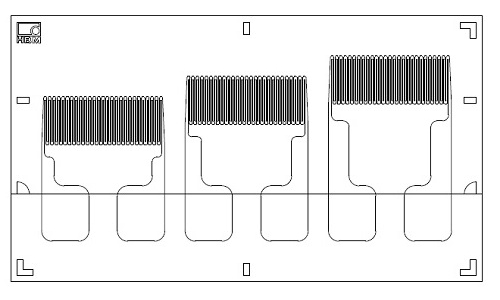

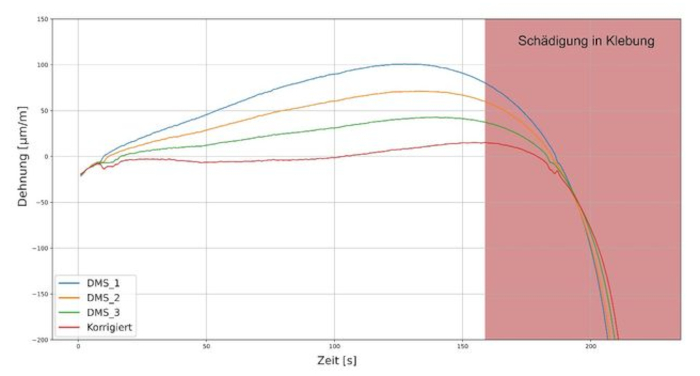

Such monitoring can already be accomplished very easily with a single strain gauge, which is bonded to the component in a particularly damage-sensitive position, the so-called zero strain point[1]. This special position, a simple overlap bonding on the surface of the joined parts, is characterized by the fact that there are no strains if bonding is not damaged. As soon as damage occurs, the strain distribution shifts, and a clear measurement signal can be recorded.

The challenge of this promising SHM approach is to position the strain gauge as accurately as possible in the previously calculated position. However, both small misplacements (<200 µm) and variations in bond thickness cause a shift in the measurement signal. The resulting change in strain must then be corrected.