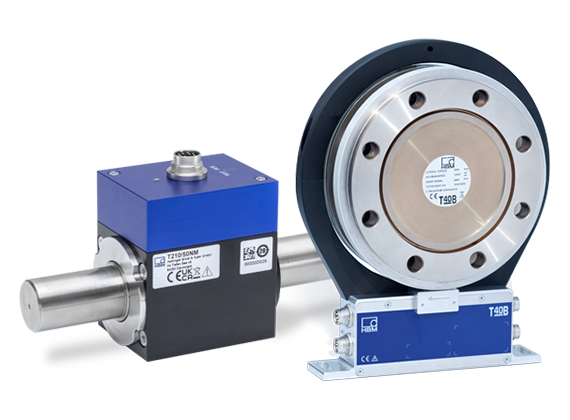

There are some things to bear in mind when selecting a suitable torque transducer. Before going into the details of technical specifications, it’s worth taking a quick look at the two different torque sensor designs: the measurement flange and the measurement shaft. Both types of sensor have advantages that are especially beneficial for particular applications.

Choosing the Right Torque Transducer: Shaft or Flange?

The Torque Measurement Shaft

The measurement shaft is a compact all-rounder for applications where maximum precision and dynamics are not a priority. Thanks to their design, shaft torque sensors can also measure very small torques – from 0.5 Nm (HBK models). For small nominal (rated) torque ranges this type takes up less space than a measurement flange and is also comparatively less expensive.

Typical applications:

- General use in test benches

- Function tests

- Measurements on micromechanical switch elements

- End-of-line testing of gear boxes, engines, motors and other components

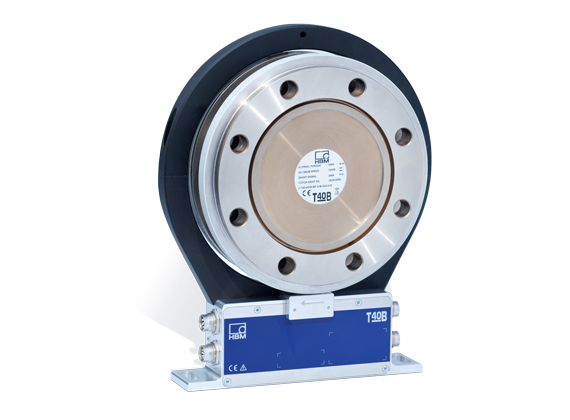

The Torque Measurement Flange

The measurement flange is short and rigid in structure. This makes it the ideal transducer for fast and dynamic measurements that require a high degree of accuracy. Additionally, torque measurement flanges are compact while also being capable of measuring very high torques. In general, they are capable of recording nominal (rated) torques up to MNm .

Typical applications:

- Electric motor, electric axle and hybrid drive testing

- Efficiency measurements

- Fatigue life analyses (endurance tests)

- End-of-line testing of gearboxes, engines, motors and components

- Standard test machines (reference transducers, transfer standards)

HBK offers both measurement shafts and measurement flanges for a large variety of applications.