How is strain measured?

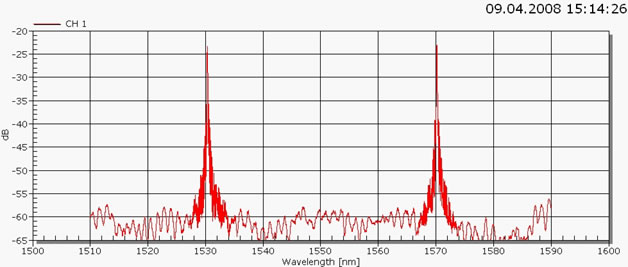

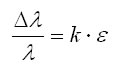

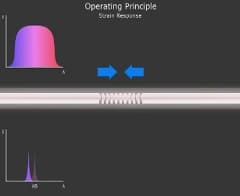

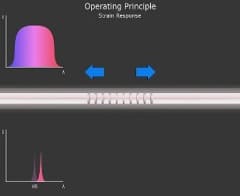

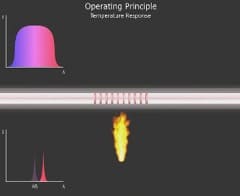

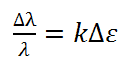

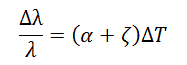

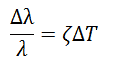

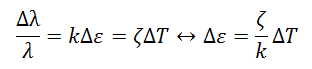

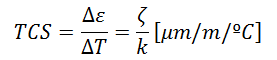

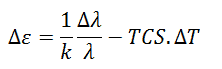

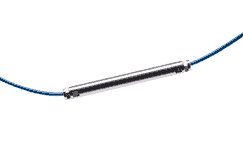

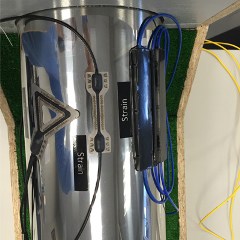

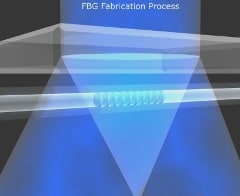

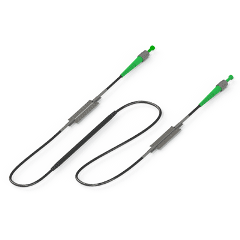

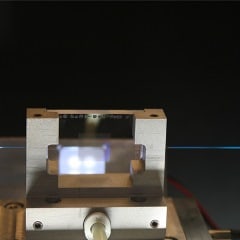

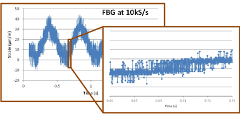

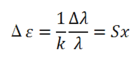

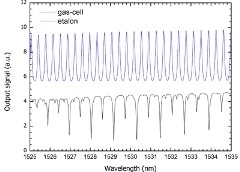

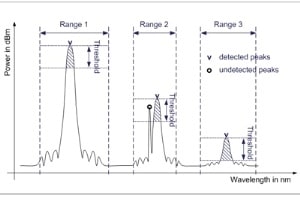

The values measured by the optical interrogator (data acquisition system) are the peak wavelengths of the narrow spectrum reflected by the fiber Bragg grating sensor. When strain at the optical strain sensor causes the wavelength to change, the interrogator detects a change in the peak wavelength that is proportional to the strain.

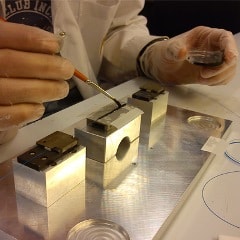

The gauge factor or the sensor sensitivity specified on the sensor packaging is used as the proportionality factor.

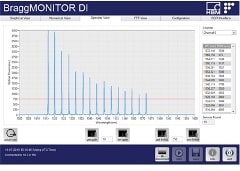

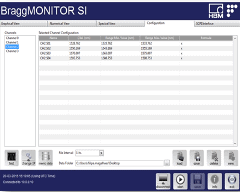

HBM FiberSensing interrogators can be used with the available graphical user interfaces, such as the BraggMONITOR, and powerful acquisition and data analysis software, i.e. catman®.