Both fatigue tests and static tests are undertaken by S&DT. Fatigue tests take much longer to complete than static tests and are based on data trending which looks for changes in the structural response over time. These can easily signify the possibility of cracks or other in-service related conditions.

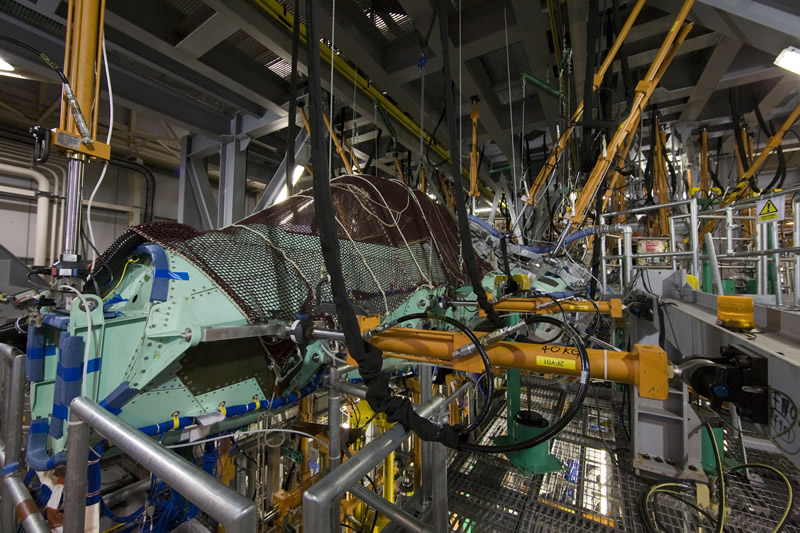

The tests are undertaken by applying various loads to different structural components in an accelerated timeframe to reproduce potential operational damage. Complex PC-based test control and data acquisition systems are used to control how the forces are applied to the different test structures and the responses carefully monitored. Test specimens are usually instrumented with strain gauges enabling real-time recording of strains generated.

S&DT’s structural tests utilise HBM’s equipment to capture and analyse data. The equipment includes a data acquisition system from HBM comprising catman® Enterprise software connected to 32 MGCplus devices distributed in eight cabinets across the test rig. The HBM equipment is fully synchronised giving BAE Systems one of the world’s largest structural DAQ systems.

The MGCplus supports a wide spectrum of sensors, transducers, fieldbus connections and standard PC interfaces making it a suitable choice for this application. The modular design ensures that it can be easily expanded or modified should BAE Systems’ requirements change.

The catman® Enterprise software suite is specifically developed for high channel-count measurements using the MGCplus DAQ system while its dedicated Measurement Data Server (MDS) performs the actual measurement enabling monitoring and evaluation in real-time. This set-up gives test engineers access to some 3,800 channels populated with HBM’s ML801 cards and AP815 connection boards terminating in RJ45 connectors for data acquisition.