HBM technology and service for building up the first German offshore wind farm

Efficiently generating electric power without polluting the environment becomes increasingly important in times of high commodity prices and growing environmental awareness among consumers. Within the scope of the OGOWin research project for building up a first prototype of a jacket-construction-type offshore wind power plant, HBM supplies and installs test and measurement equipment for a test plant in Bremerhaven, Germany. The challenge is to install the equipment such that it also withstands the extreme stresses to which the production models will be subjected later when used in rough sea conditions.

Offshore wind farms comprise many wind turbines installed far off shore in the open sea and permanently producing clean current. This is an attractive concept which, however, is not easy to implement because of the stresses resulting from wind, waves and saltwater to which the materials used are subjected. For this reason, the German Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (BMU) subsidizes the research and optimization of disarrayed foundation structures for offshore wind power plants (OGOWin) regarding material usage, the assembly process and new manufacturing methods for the carrying structure of wind power plants. Prior to the actual use of the foundation structures on the sea bed, the OGOWin project focuses on onshore research of the offshore plants.

The two main components of a wind power plant are the carrying structure (jacket + tower) and the actual nacelle with the rotor blades for generating electric power from the wind. The OGOWin project focuses on the jacket as the object of study. Researchers aim at minimizing material usage, because steel is expensive and a jacket weighs about 350 tons. In addition, the status of the wind power plant is to be continuously monitored. Maintenance cycles and the residual service life are inferred from the results.

Criteria of Selecting the Measurement Technology: Positive Experiences, Convincing Results, Competent Service

The Fraunhofer Center for Wind Energy and Marine Technology (SWMT) in Bremerhaven, Germany, is responsible for the design and layout of the test and measurement equipment at the carrying structure. HBM has built up and installed the test and measurement equipment on behalf of the Fraunhofer CWMT. HBM was chosen, not least because of the positive experiences and convincing results with FINO1, a research platform for offshore wind power for which HBM provided the test and measurement equipment (electrical strain gages installed fully waterproof) already in 2003. It had been used without any problems for several years until an exceptionally strong storm destroyed parts of the platform. Moreover, HBM has a competent and international service team enabling problems to be quickly and reliably eliminated on site. And last but not least, HBM offers both technologies from a single source so that reproducibility is guaranteed.

The Measurement Chain

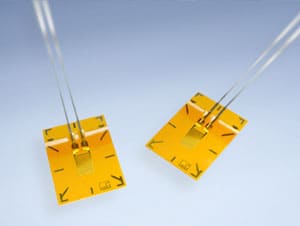

HBM's tasks in the framework of the OGOWin project include installing electrical and fiber-optical strain gages at the "stressed" points of the jacket, cabling the HBM amplifiers and transmitting the measured values to the Fraunhofer Center. The goal is to test both technologies (optical, fiber-Bragg-grating-based strain gages and electrical strain gages) with respect to reproducibility of test results and suitability for use in offshore wind power plants.

For implementing the test and measurement concept, HBM provided the required hardware and software (MGC amplifier, opto-electric interrogators, catman software) and installed about 70 strain gages on the jacket. Many measuring points were doubly configured - i.e. strain gages of both technologies were installed. The focus is on analyzing the static and dynamic behavior of the newly developed cast-iron nodes used in this design for the first time. The measuring points were covered with multiple layers to enable them to withstand many years of continuous use in a water depth of up to 40 meters. Test data is transmitted by saltwater-proof cables to the amplifier located at the foot of the tower and sent to Fraunhofer at periodic intervals. There, data is visualized, converted and analyzed using HBM's catman software.