DIN EN ISO 376

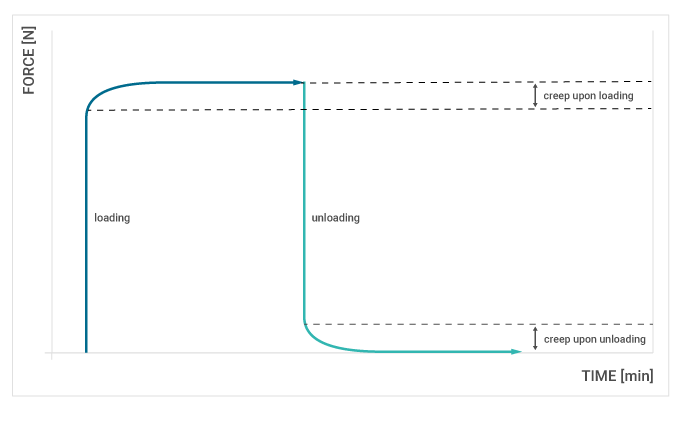

DIN EN ISO 376 describes a calibration process for force transducers or measurement chains (generally referred to as force-proving instruments in the standard), which is employed for transducers that are to be used as reference force transducers or transfer standards, or is applied when there are stringent requirements for the determination of measurement uncertainty. The procedure involves preloading with nominal (rated) force several times, step by step, loading over eight or ten load stages in three mounting positions each rotated by 120°, and a creep measurement.

Next, each calibrated force transducer is provided with a calibration certificate, which states the transducer’s class and evaluates and documents the characteristic values. The calibration certificate also contains information on the standard test machine used, the signal conditioner employed, and the ambient conditions prevailing during calibration (temperature, air pressure, etc.)

Tip: You can find an interactive calibration certificate here. The individual elements of calibration as per DIN EN ISO 376 are explained step by step.