Utilizing strain transducers for greater accuracy in forging

One of the world's largest automotive component suppliers, Hirschvogel Automotive Components, based in Pinghu, China, is utilizing HBM’s SLB strain transducer and MP55DP amplifier system to monitor forging forces for improved quality.

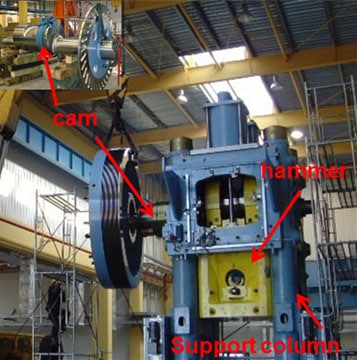

Forging is used in manufacturing to shape metal through localized compressive forces. It is carried out on a heavy-duty forging machine in which a cam mechanism transfers the rotational movement of an electric motor into the linear reciprocating motion of the hammer or so-called slide block.

High forces are needed during forging and the force applied to a work piece may exceed the nominal force of the forging machine. The working force can reach several MN: the recorded world maximum force was 800 MN. This makes forging a particularly dangerous activity both to the machine and to personnel working in the area.