Measuring Systems During Development

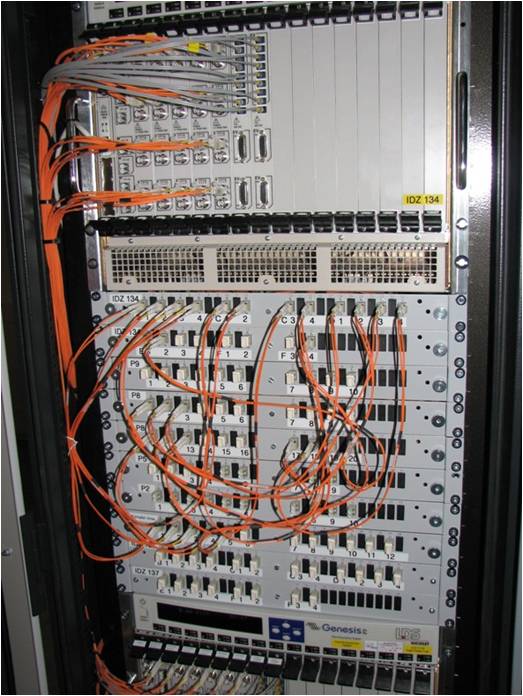

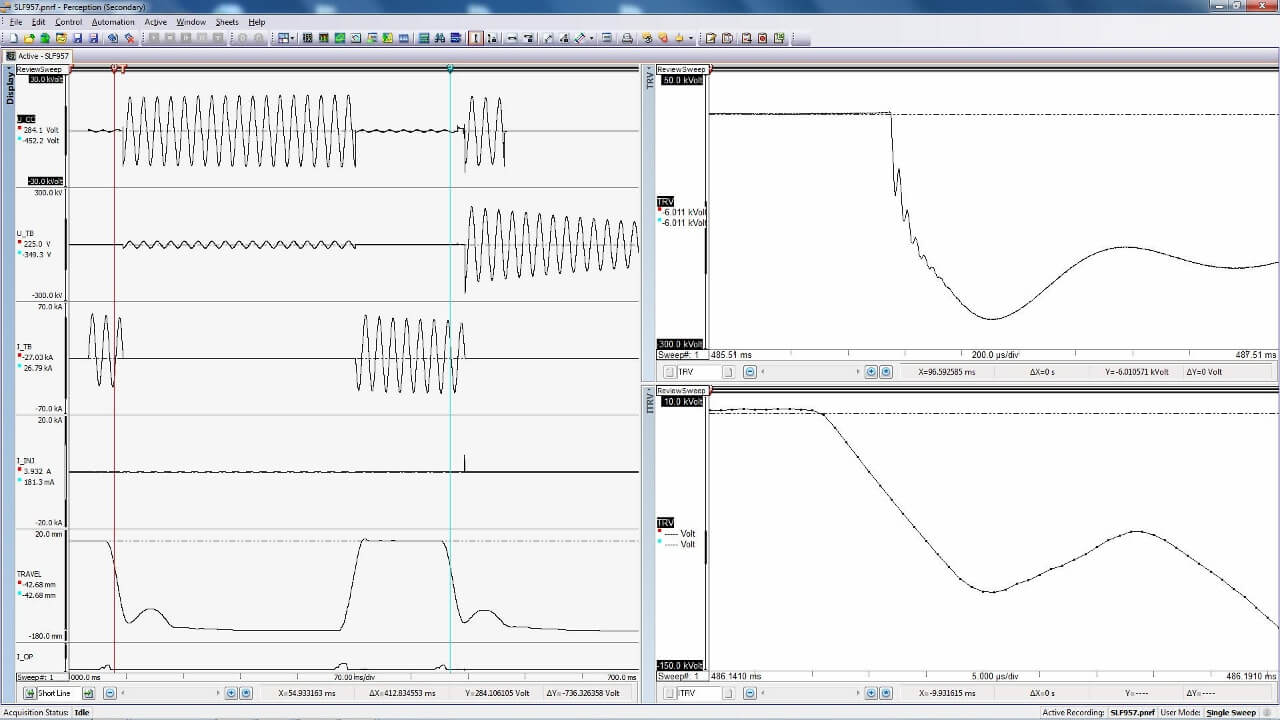

The extreme stresses and high sampling rates (up to 100 mega samples per second) are clearly very challenging for the tools used. Back in the 1980s, ABB was already pioneering the design of digital test data systems. This early work formed the basis of what today has become a commercial product – the HBM Genesis HighSpeed family for transient logging of data. ABB still works closely with HBM as it develops the system, now in its ninth generation.

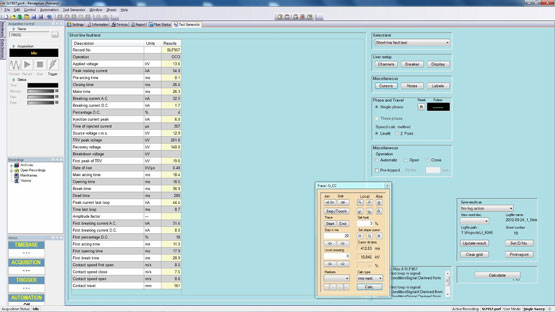

"It's important to us that the system is still being developed by a commercial enterprise with a large number of other users, and that we can access support and updates. We now use Genesis and Perception in all our labs, and we have a healthy dialog with HBM with regard to improvements. It's reassuring to have a uniform and effective set of tools that are constantly being updated," adds Kjell Korhonen.

Flexible System

The laboratory has access to four measuring racks of the Genesis HighSpeed system. The system is flexible because the required modules can be plugged directly into the rack. For large-scale tests, multiple measuring racks can be combined.

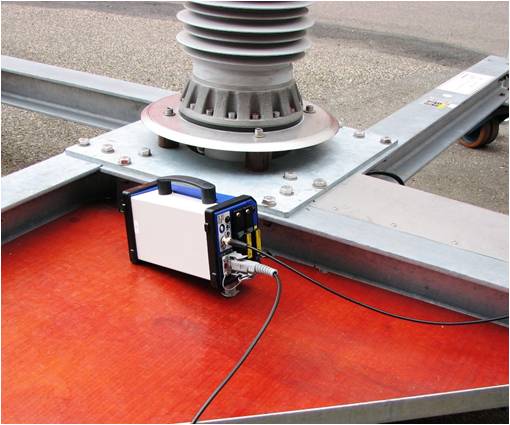

Each measuring rack has space for a receiver card with four channels each. Fiber optic cables link the channels to digitizers, which convert the signal from analog to digital and pass it on to the Perception software for verification and processing. The laboratory and the test equipment at Ludvika are operated in two shifts with around 30 highly qualified engineers.