Estimating the measurement uncertainty for zero-point related measurements

In these measurements, the zero point is important. These are typically long-term measurements on buildings and fatigue tests on components. If the zero point changes during measurement tasks of this type, the result is an additional measurement error. The measurement uncertainties already discussed in the last part of this series must be added to the ones noted in this section.

Thermal expansion of the DUT, temperature response of the strain gauge

The material being measured has a coefficient of thermal expansion. The thermal expansion will not be measured, as it is simply the result of temperature as an influence quantity. The measuring grid also has a coefficient of thermal expansion as well as a temperature coefficient of the specific electrical resistance. Since only strains induced by loading are of interest in ESA, the strain gauges that are offered are adapted to the thermal expansion of specific materials. However, all these temperature coefficients are themselves a function of the temperature so this compensation will not be entirely successful. The remaining deviation ΔƐ can be calculated with a polynomial. The coefficients of the polynomial are determined batch-specifically and are specified by the manufacturer on the strain gauge package.

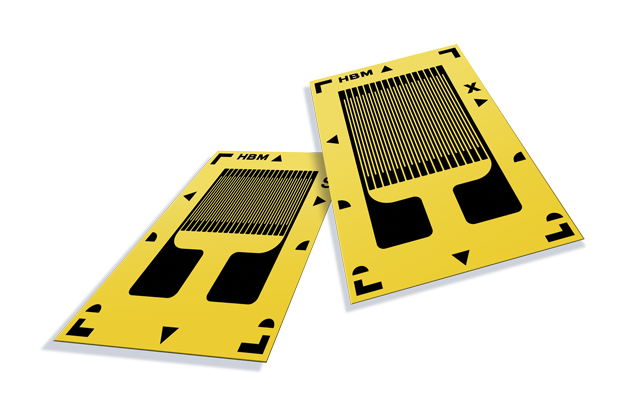

An example of a strain gauge (HBM type LY-6/120) can be found here.

The current should be inserted in °C (but without dimensions). Then the remaining deviation (apparent strain) will be determined in μm/m. For a temperature of 30 °C, the resulting apparent strain is -4.4 μm/m.

If the ambient temperature deviates significantly more from the reference temperature (20 °C) or if the strain gauge is actually adjusted incorrectly, much greater deviations will occur. These are systemic in nature and can be eliminated by calculations (online as well). On the other hand, the equation already exhibits an uncertainty that increases by 0.3 μm/m per Kelvin of temperature difference from 20 °C. At a temperature of 30 °C, the uncertainty of the polynomial is 3 μm/m.

The only requirements for the correction calculation are to know the thermal expansion coefficient of the material and the ambient temperature.

Self-heating

Self-heating

This refers to the increase in temperature resulting from converted electrical power in the strain gauge. The heat output is determined as follows:

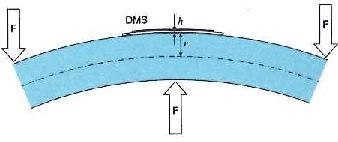

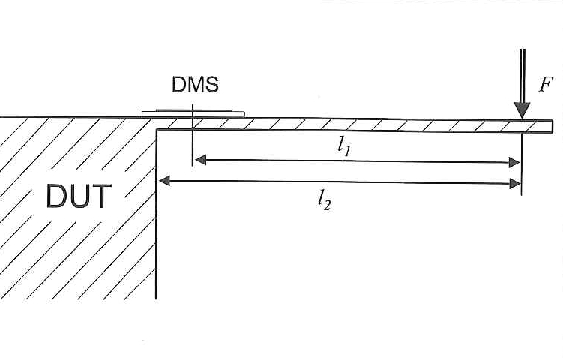

For a root mean square value of 5 V for the bridge excitation voltage and a 120 Ω strain gauge the resulting heat output is 52 mW. A strain gauge with a measuring grid length of 6 mm applied with a thin layer of adhesive on steel or aluminum is able to give off the heat sufficiently to the measurement object. A small temperature difference will nevertheless arise between the strain gauge and measurement object, which will lead to an apparent strain (see above):

If the temperature of the adjusted strain gauge is just one Kelvin above the material temperature, there is already an apparent strain of -11 μm/m (ferritic steel) or -23 μm/m (aluminum). The measurement uncertainty can be roughly determined with a simple experiment - the excitation voltage is connected while the load is not applied to the component. In the temperature increase phase, the measured value will drift slightly (zero drift). The greatest difference between measured values during this thermal compensating process corresponds roughly to the maximum expected deviation.

Lower excitation voltages provide a remedy (1 V generates only 2 mW). Strain gauges with higher resistances are also advantageous in this respect.

For components with poor heat conductance (plastics, etc.) and when very small strain gauges are used, lowering the excitation voltage is indispensable. Caution is always advised when working with rapidly changing temperatures. Compensation effects resulting from adjusting the metal foil of the strain gauge to the material being examined have a time constant.