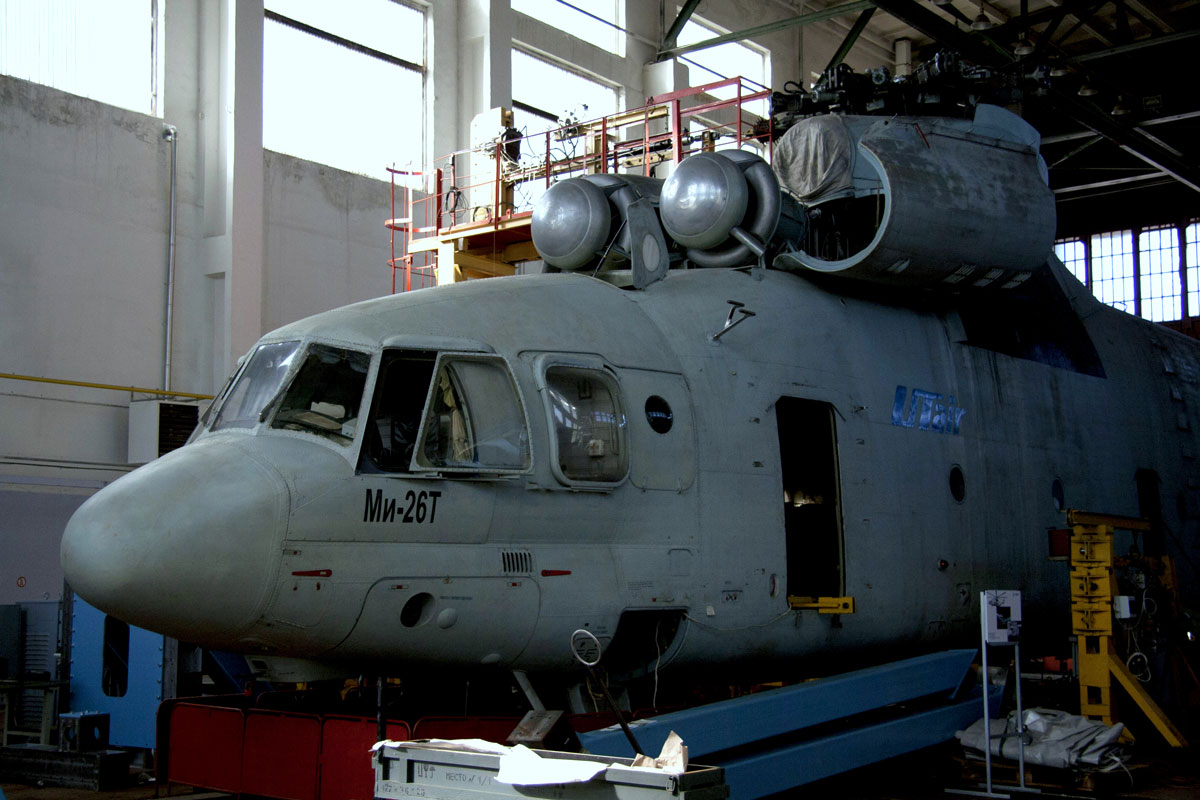

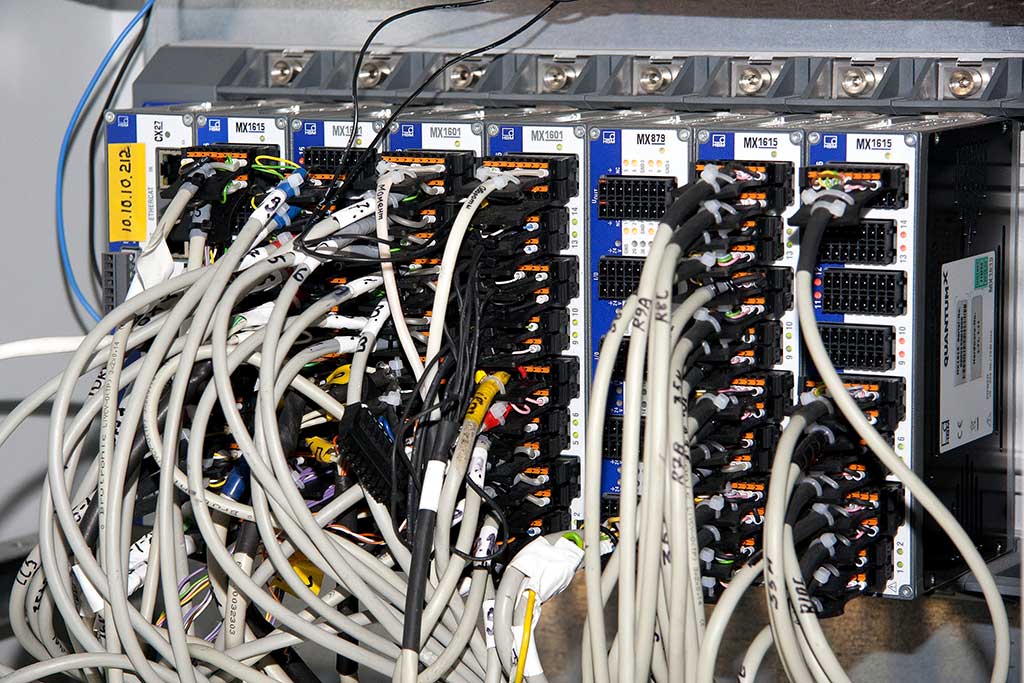

Structural testing of airframes with QuantumX at AVIATEST

AVIATEST: Takeoff with QuantumX

Aviation nowadays is one of the key transport industries carrying millions of passengers on a daily basis. Needless to say safety in the air is a top priority and Latvian company AVIATEST has been carrying out rigorous and comprehensive aircraft tests for decades. State of the art technology is of crucial importance in performing such sophisticated tasks and HBM's data acquisition system QuantumX is an integral part of the company's daily work.

Back in the days of the Soviet Union, AVIATEST usually performed full-scale tests with a dozen of Soviet U-built planes and helicopters. Nowadays it’s all about the specialization - AVIATEST tends to focus on different longevity, resources and static strength tests.

Established more than forty years ago AVIATEST now cooperates with aviation companies based in the European Union as well as Russia. Similarly to Latvian aviation as a whole, AVIATEST aims to serve as a bridge between the West and the East.