With testing well under way, the client had additional requirements for testing and was questioning whether the equipment that had been selected could provide the necessary measurement data and accurate results. HBM was quickly brought in to take the required measurements using strain gauges and a data logging system to prevent delays in the work and potential reworking.

The project consisted of testing a machined pipe for injection valves for use in oil and gas wells as well as assisting the client with verifying calculations carried out using FEM analysis. Due to extreme conditions in the well, the verification points were difficult to reach, and all the equipment and calculations had to be quality assured.

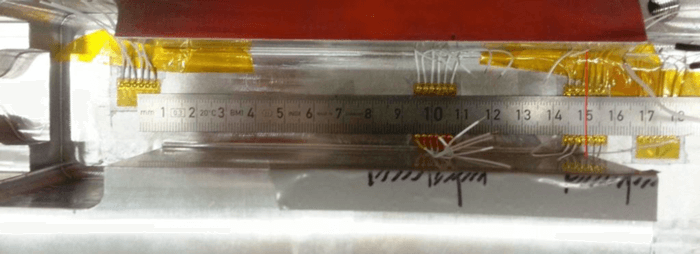

With HBM’s help, extra strain gauges were installed at the verification points. To ensure accurate measurement data, the measuring points on the pipe were cleaned, sanded down and polished before the strain gauges were fitted. In total, 11 strain gauges were placed on the pipe using quick-drying glue and were connected to the QuantumX amplifier.

Once all the strain gauges were in place, the pipe was pressurized up to 690 bar in stages using N2. The client also wanted to leak-test a component on the pipe, so therefore gas (rather than liquid) was used in the testing. HBM’s catmanEasy software was used to adjust the necessary settings on the amplifier and to log data from the strain gauges and other sensors during testing. The measurements could be directly compared with the client’s calculations, saving them a lot of subsequent redesign and calculation work.

“HBM did an excellent job. They were fast, efficient, and even flexible when we needed additional help. We were pleased that HBM could assist us on short notice and help out with analysis and expert assistance during the testing. It saved us from a potentially disappointing outcome for our client.”

Gunleik Sandsmark, IRIS’s project manager.

Successful installation

Both IRIS and its client were extremely pleased with the assistance they received from HBM:

“HBM did an excellent job. They were fast, efficient, and even flexible when we needed additional help. We were pleased that HBM could assist us on short notice and help out with analysis and expert assistance during the testing. It saved us from a potentially disappointing outcome for our client,” says Gunleik Sandsmark, IRIS’s project manager.

Thanks to good communication and instruction, the client can be assured that the right measurements were taken and the results were accurate. The strain gauges and the logging provided assurance that the pipe was of the required quality and the strength of the pipe was able to be approved on the spot. With a measurement accuracy of ±3 percent, it was concluded that the installation was a success.

IRIS has always used HBM as a supplier ever since the institute was established, and thinks of HBM as being reliable, experienced and of high quality.

“Our client is very satisfied with the delivery and is likely to use HBM in new projects,” concludes Sandsmark.