The Passy hydroelectric plant, the most important power plant in the Haute-Savoie department of France, generates electricity using water held back by dams and glaciers. In late 2013, major civil engineering works were planned in the vicinity of a "penstock", or pressure pipe, transporting water from a glacier, and it was necessary to ensure that these works would not have any impact on the solidity of the penstock or its attachments.

This type of pipe, often seen on mountainsides, takes the form of a large metal cylinder featuring binders (i.e. stranded ropes) installed to help withstand the internal pressure. The section that needed to be monitored for possible deformations was 40m-long and held up by 4 supports. "To implement this monitoring, we called in HBM, who had already handled an application of this type at another one of our facilities. HBM proposed a turn-key solution and took on the design, installation and data archiving. Based on its success, we adopted the same approach for this new application," explains Claire Pérot, mechanical engineer at EDF's Hydroelectric Engineering Center.

The customer

EDF - Direction Production Ingénierie

Centre d'ingénierie Hydraulique

37, rue Diderot - BP176

38042 GRENOBLE Cedex 9

Information EDF sur le projet Passy

A system in a challenging environment

Monitoring was provided by traditional foil strain gauges. These strain gauges, 16 in total, were installed with the support of a company specializing in works on these kinds of sites, which require safety precautions for technicians exposed to falling hazards, etc. "In order to access the deformation data of interest to us, we positioned strain gauge in generator configuration along the penstock, to the right of the penstock supports, supplemented with 2 strain gauges (located at 3 o'clock and 9 o'clock) 2 m uphill from each support. We mathematically combine the data provided by these different strain gauges to arrive at the desired synthesis values," adds Claire Pérot.

The water running through the penstock originates from the glacier and is around 5ºC (41ºF), in both summer and winter. It does not vary much, so there are no major temperature compensation issues to deal with, except when EDF needs to empty the penstock. In summer, the ambient temperature can rise to 30ºC (86ºF), or even higher. So taking temperature readings on the penstock allows us to compensate for variations in extensometric measurements.

"The strain gauges are wired in half-bridge circuits with a thermal compensation strain gauge to take temperature variations into account. Because of the significant distance between the strain gauges and the control unit (up to 80 m at the greatest distance), it was necessary to compensate for line lengths, which we did by using a 5-wire circuit," explains Pascal Chaffot of HBK France's Engineering department, who was in charge of implementing the application. In addition to the penstock temperature mentioned above, measurements were also taken for the ambient air temperature and the control unit's internal temperature.

The Control Unit

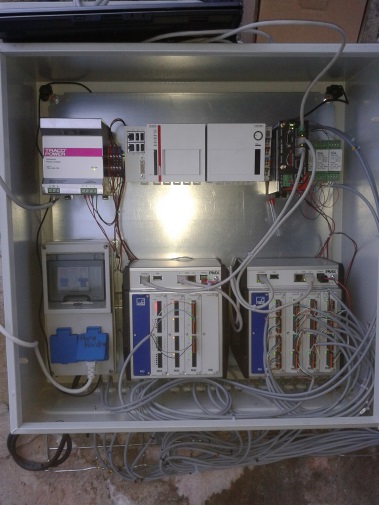

The control unit, located in the vicinity of the penstock, is subject to significant temperature fluctuations, enduring both the harshness of winter and the scorching heat of summer. To obtain the measurements, HBM installed two PMX chassis, suitable for use between -10 and 60°C (14 to 140ºF). The sampling frequency (up to 38.4 kHz) and the resolution (24-bit) are more than adequate for applications of this kind. The digitized data are transmitted over an Ethernet connection to a rugged industrial PC manufactured by Beckhoff. The PC is fitted with HBM's catman software, here configured to perform monitoring tasks. "Actually, HBM does have other devices suitable for this application, but given that the application is not expected to evolve, we proposed a 'strictly minimal' solution," notes Pascal Chaffot.

HBM stores the data

The data are transmitted to an HBM server by a 3G router by Sixnet, a company acquired several years ago by Red Lion, a member of the Spectris Group (along with HBM). When predefined thresholds are exceeded, EDF is alerted immediately by email. Otherwise, the contract stipulates that a results summary will be sent out every month in Excel format. In this application, HBM will not be conducting the data analysis because EDF wanted to handle this itself, but that is a service HBM could also provide.

As we have seen, HBM handled the entirety of this application, starting from the schedule of requirements drafted with EDF. Although the instrumentation is quite conventional in terms of product selection, its installation in a difficult environment took a great deal of expertise in strain gauge positioning. This called for working at high altitudes, with specialized operators. You also have to know to make allowances for the fact that you are installing devices on structures which are often oxidized, which also requires a certain amount of experience. It was even necessary to install protectors on the cables to prevent damage from attacks by birds of prey, which are common on the mountain.