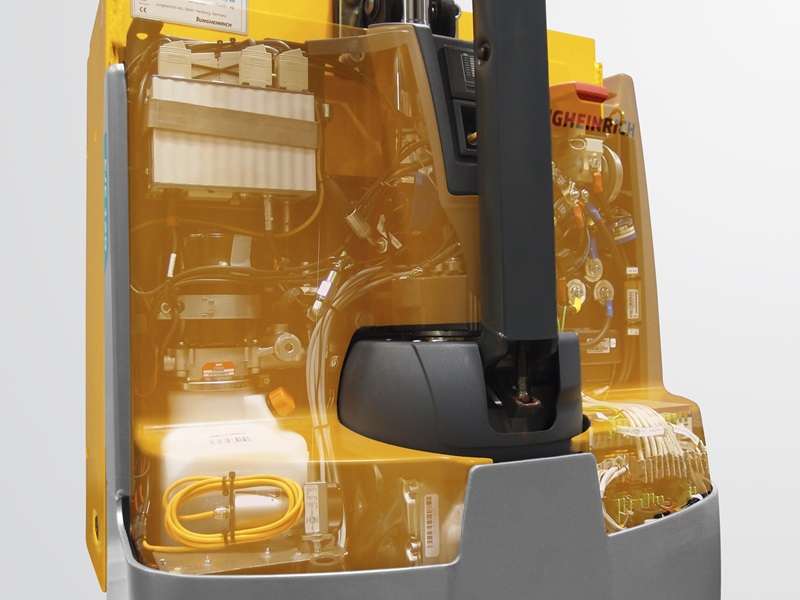

QuantumX “Undercover Operation”: HBM Enables Jungheinrich to Take Product Quality to the Next Level

Jungheinrich is a world leader in fork lift truck, warehouse, and material flow technology. The listed company provides innovative warehouse logistics solutions offering high functionality, reliability, and excellent quality. These are the result of extensive testing prior to and also after the market launch of new products. Jungheinrich, for instance, relies on extensive product testing at the customers’ premises. The insights about actual loads in day-to-day operation gained under real conditions are not only used to validate the values forecast during product development, the specialists also use the practical test results to continuously improve their products.

For measurement and analysis, Jungheinrich relies on high-performance solutions from HBM such as the universal QuantumX data acquisition system.