Long-standing Expert in Thermal Testing

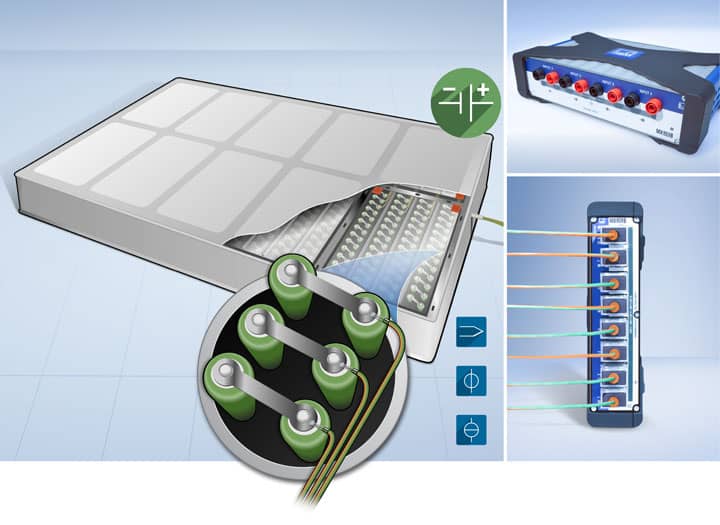

HBK develops and offers the necessary components for thermal validation measurement chains for years. These solutions are covered by electrical, optical, or combined - hybrid - measurement chains.

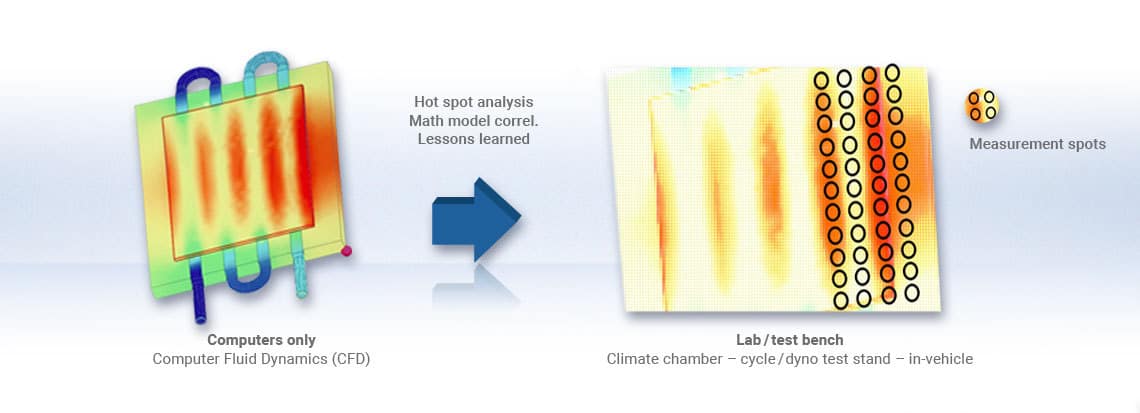

Already combustion engines must deal with the fact that power generates heat. With the electrification of mobility and the upcoming need to develop thermal testing methods also here, HBK looked at existing processes and refined them from a new perspective. Thus, all the experience and knowledge has been processed and adapted to also become a specialist for eMobility thermal testing and within this, for battery testing.

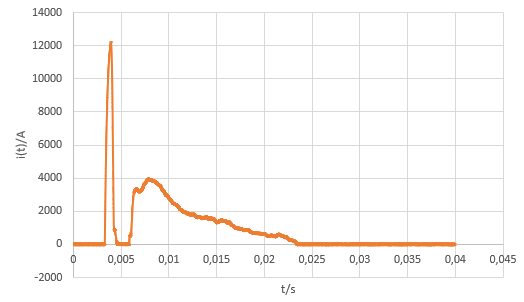

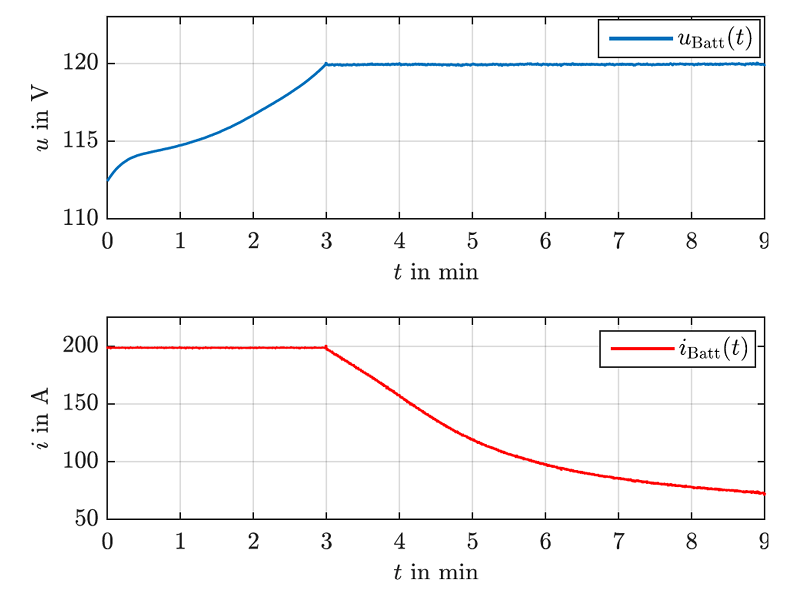

The HBK energy storage thermal testing system measures parameters including voltage, current, temperature, humidity, cooling flow, pressure, and talk-to-battery management system. Calculations are made for power, efficiency, hot spot monitoring, visualization, and analysis. Automation deals with test control and safety.

An HBK data acquisition and analysis solution provides thermocouple measurements for the exterior of the electric drive train and for investigation deep into the battery, including cell voltages, overall voltage, and current measurement. Universal inputs cover universal flow, pressure, humidity, and other required parameters.

HBK is your cost-effective, one-stop-shop solution provider for thermal, mechanical, and electrical test specimen analysis.