The challenge: A new material monitoring system

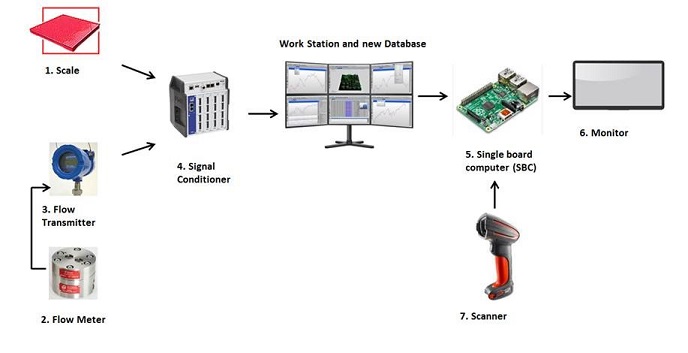

Sean Minogue, a structural engineer in Sea Ray’s product development and engineering group, came aboard in 2012, charged with updating many of the shop floor processes at Brunswick’s multiple boat-building facilities, all focused on cost and weight savings and on allowing them to build boats to higher tolerances. The previous methods used to monitor consumption of fiberglass and resin were something less than ideal. For example, tracking fiberglass consumption required monitoring the revolutions of a wheel around which the fiberglass filaments were wound; resin consumption was calculated based on the output of a stroke counter linked to a pneumatic pump. Even when both devices were operational, they tended to be inefficient and not particularly exact.

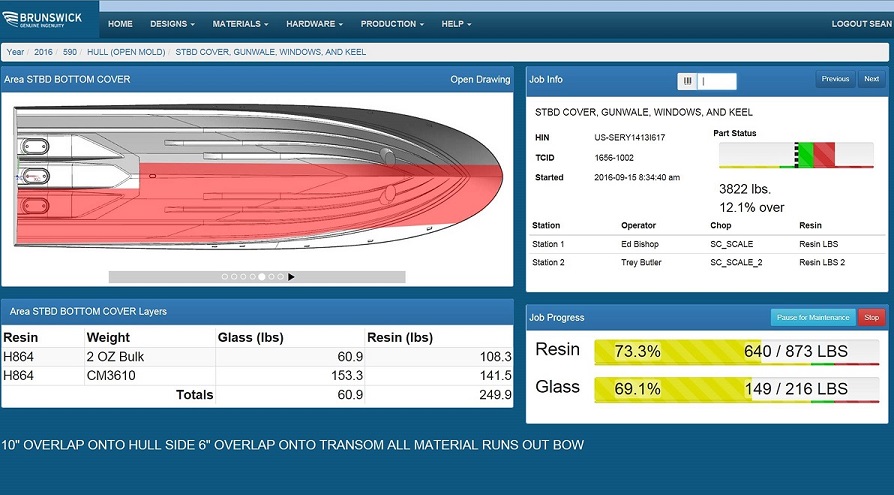

In his proposal for a new system, Minogue explained, “The system will track resin, chop, and other bulk material usage by part. This gives us the much needed visibility of our work in progress by comparing usage to requirement data in real-time. The system is expandable to track pull weight data, SKUs, labor hours, cure cycles, takt time (average time between the start of production of one unit and the start of production of the next one), historical weight data, and most of all, provides live target data to the operators.”