SEAT Tests Vehicles Faster With HBM’s Autonomous DAQ System

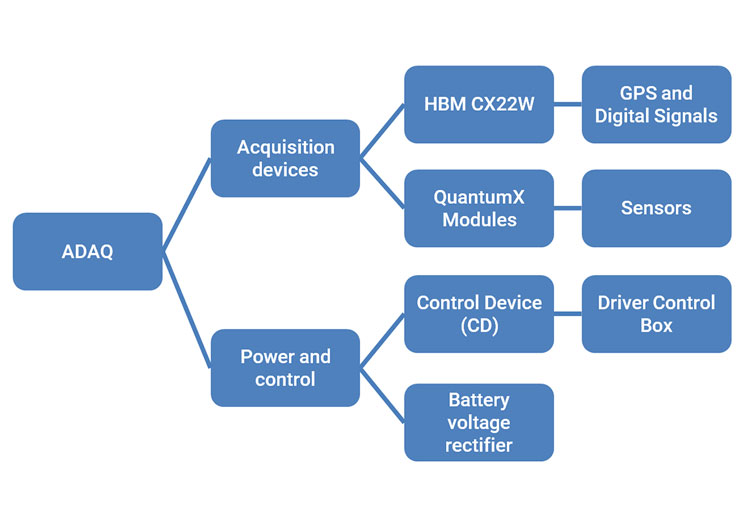

Volkswagen Group specifications require that vehicles are tested during the development phase at SEAT in order to ensure that quality and durability standards are met. The challenge for the SEAT team was to set up a data acquisition (DAQ) system that is fast enough to provide more precise control over the instrumented parts and the entire data acquisition. The team developed an autonomous acquisition, communication and analysis process that meets all requirements – the ADAQ system.

Together with the Polytechnic University of Catalonia, SEAT has developed a system for an Autonomous Data AcQuisition process, also called ADAQ. It is comprised of QuantumX DAQ modules, catman software and an electronic circuit that guarantees both the power supply for all devices and the vehicle-pilot interaction. The following DAQ systems and sensors were used: the QuantumX MX840B universal module, the MX1615B strain gauge module and one CX22B-W datarecorder, thermocouples, accelerometers, strain gauge bridges, displacement sensors, and, in addition, 14 CAN channels and GPS. Due to the wide range of conditions in which the vehicle is likely to be tested, the QuantumX equipment was securely mounted in the vehicle.