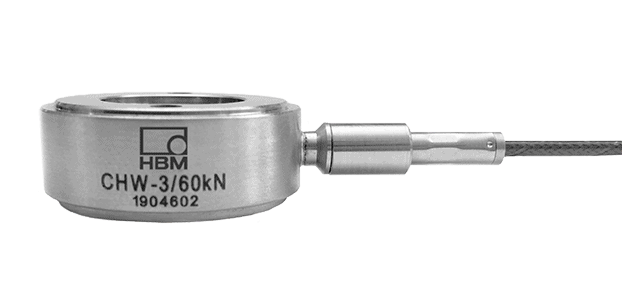

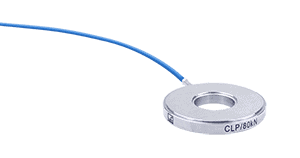

The decision of whether to use piezoelectric force sensors or sensors based on strain gauges depends on the application. Piezoelectric sensors are preferable, particularly when the application has one of the following requirements:

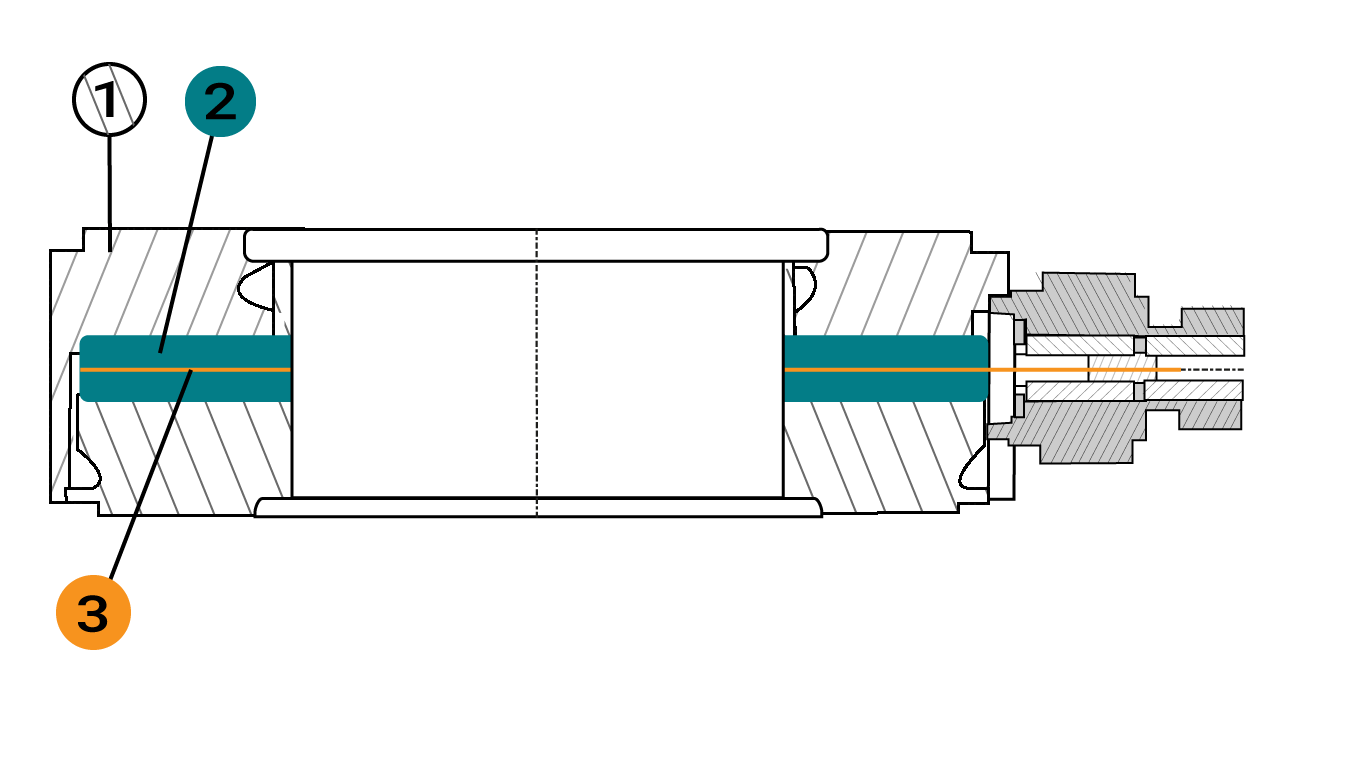

- Confined space for sensor installation

- Measurement of small forces with a high initial load

- Wide measuring range

- Measurement at extraordinarily high temperatures (up to 300 °C)

- Extreme overload stability

- High dynamics

Strain gauge-based sensors, too, offer advantages over piezoelectric force sensors; for instance, they enable tensile force to be measured and often are more economical. In addition, they provide better accuracy, drift-free measurement, and static calibration. When it comes to reference measurements, there is no alternative to strain gauge measurement technology.

We recommend checking, in any case, which transducer meets the requirements of the measuring task at hand in the best and most cost-effective way. When the decision to use a piezoelectric sensor has been made, there remains the question of which force transducer is the right one. In the following, we will take a closer look at the typical fields of application to enable you to make the right choice.