How HBM measurement technology helped Trasko Automatyka Sp. z o.o. develop an assembly line immune to electromagnetic noise

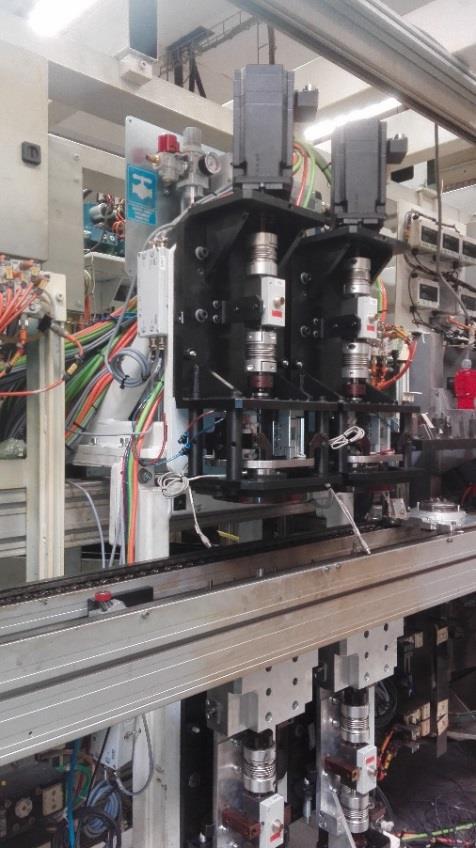

Did you know that HBM’s measurement technology consists of a special shielding concept, making it immune to electromagnetic interferences of any kind? By using the special shielding concept from HBM, Polish automation company Trasko Automatyka Sp. z o.o. was able to develop an assembly line with torque control units providing safe and clear results for quality control. In a previous setup using equipment from other suppliers, this assembly line was heavily affected by electromagnetic noise causing severe problems for the end-of-line quality control.

The challenge: A consistent shielded system

By facing the task of re-building and re-designing the assembly line, Trasko Automatyka Sp. z o.o. did a full review and check of the control systems used. One big challenge was the creation of a consistent system, considering the many parts, devices, control units, robots and mechanics used. For the measurement systems used, this means that they should be well shielded but not emit electromagnetic noise from themselves.

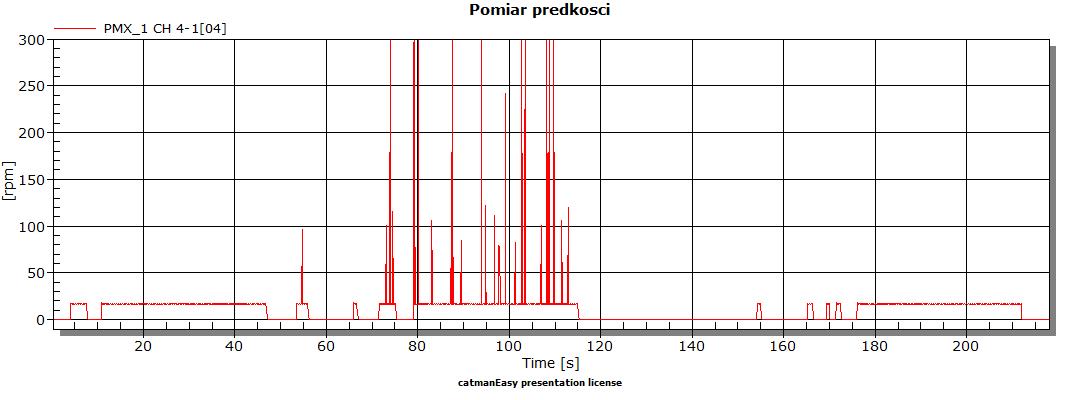

The strong influence of electromagnetic noise on the torque measurement results caused by missing accuracy of the sensor as well as insufficient shielding can be seen in this chart:

HBM’s solution: The Greenline shielding design

By using the HBM measurement technology with its special shielding concept against electromagnetic interferences, Trasko Automatyka Sp. z o.o. was able to set up a process control system providing reliable results.

They used the following setup:

- A T20WN torque sensor for measuring signals

- The PMX signal conditioning system for production control

- The catman software for measurement visualization and analysis

- Special double-shielded cables to connect the different parts of the measurement chain.

Protecting measurement systems against electromagnetic interference has been a long-time specialty of HBM products. For example, all electrical/electrotechnical components of the complete measuring chain are tested and technical safety issues are analyzed in HBM’s accredited in-house laboratory, thus ensuring that all normative requirements are satisfied.

Finally, a decisive factor for successfully building an “immune” measurement chain in the assembly line was the use of a special shielding design (“HBM Greenline”), ensuring safe and failure-free operation. Greenline-protected equipment neither emits any disturbances into the environment nor excessively loads the mains power supply.

Using this setup, the complete measuring chain is fully enclosed in a Faraday cage through the unique design of the cable shield. The cable shield is flattened, connected to the transducer housing, and routed to the amplifier housing through conductive connectors. These measures substantially reduce the effects of electromagnetic disturbances. Following are practical hints on how to ensure the shielding design:

All components of the measuring chain (including all cable joints, such as connectors and couplings) have to be surrounded by a closed, EMC-tested shield. Shield transitions must be realized in the form of flattened, closed and low-impedance joints. This is ensured if original HBM connectors are used.

An important feature is the separate shielding covering the wires for the sensor and the second shielding for the amplifier. To gain perfect EMI protection, the amplifier as well as the second shield have to be connected to the ground. This guarantees a complete separation from the EMI. This principle is stated in the HBM “Greenline Concept” as a fundamental design for robust and secure measurement.

Safe and stable measurement results with HBM

Thanks to the introduction of a solution based on HBM’s products, customers gain certainty and get back the quality check on the highest level. The PMX amplifier proved itself in harsh environment with electromagnetic interferences and guaranteed reliable measurement results and improvement of production’s results.

A variety of control-measurement electronics occurs in an industrial environment, and thus, electromagnetic interferences force usage of equipment which fulfils the requirements of standard [1] for immunity and emission regarding the electromagnetic compatibility of electrical devices working at voltage lower than 1000V AC or 1500V DC used in industrial processes. The additional aspect interfering the work of devices is also the usage of data transfer on Wi-Fi, Bluetooth, RFID etc. interfaces that leads to interferences in radio frequencies within a range of 9 kHz up to 400GHz.

The operation in such ranges of frequencies also leads to electromagnetic interferences. To fulfil those requirements, one should choose a control-measurement equipment which has test certificates of EMC standards.

Photos provided by Trasko Automatyka Sp. z o.o. company (www.trasko.eu)

Analysis of measurement results: Biuro Inżynierskie Maciej Zajączkowski