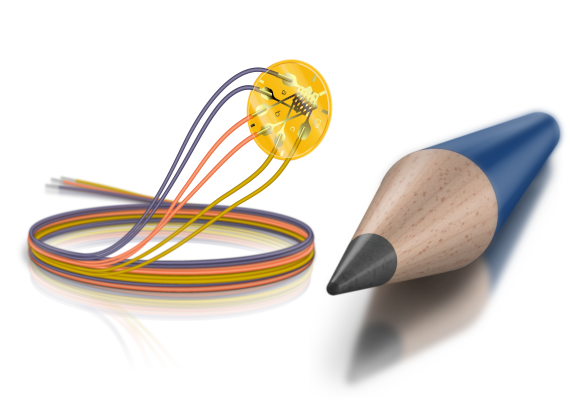

In the course of our daily lives, we have to place trust on the reliablitiy of electronic components integrated in cars, smartphones, airplanes, and countless other devices. In many of these products printed circuit boards (PCBs) are integrated. The reliability of complex electronics and overall electrical systems is a result of experienced development and intensive testing.

PCBs are exposed to mechanical and thermal impacts not only during their manufacturing process, but also during their transport and in action (for example: deformation, misuse, vibration, shock, thermal exposure).

During the manufacture of PCBs, the following malfunctions and stresses may occur:

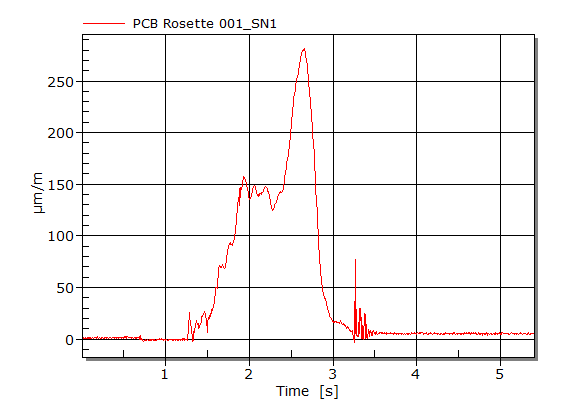

- Bending strain during the installation of connectors, power rails, cooling plates, contact pins, solder terminations, or battery holders

- Breakage during mounting of surface-mounted device (SMD), surface-mounted technology (SMT), and through-hole device (THD), through the hole (THT) and pin in hole (PIH) fitting

- Stress cracks and dislodging of solder points with ball grid arrays (BGA)

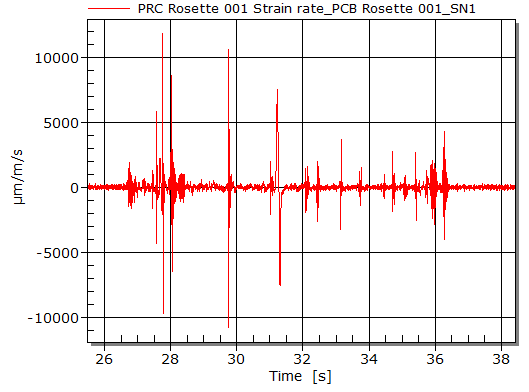

- Transient strain peaks during separation (determination of critical strains/shear strains during separation)

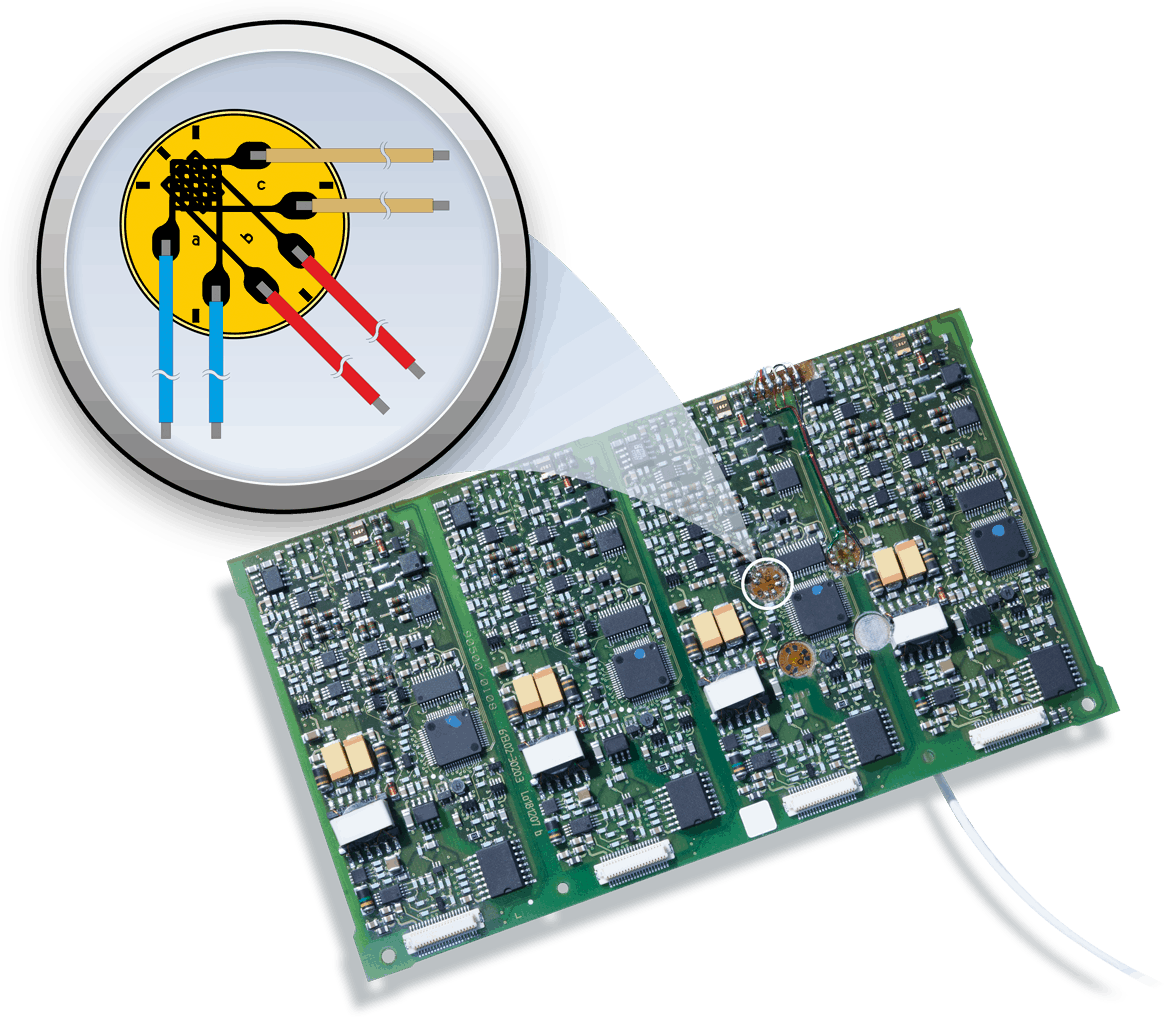

- Elevated mechanical stress (strain) that occurs due to press fitting, screw tightening, or encapsulation processes in housings

- Broken SMD capacitors due to high bending stress in other steps of the process

- Hard touchdown of the test probes during the ICT test

During transport and operation, the following impacts could lead to a malfunction:

- Mechanical load (static)

- Vibration and splicing (dynamic)

- Thermal effects resulting in cracks caused by thermal expansion (differing α values of housing, heat sink, printed circuit board, and electronic components)